Plant managers, who may be deterred by the initial cost of variable frequency drives (VFD), may find a new fact sheet released by Motor Decisions Matter a useful way to assess the many benefits of this technology. VFDs are devices that improve the efficiency of electric motor-driven systems by varying motor input frequency and voltage to control motor speed. Energy costs are 95 percent of the motor total cost of ownership, but VFDs can dramatically reduce the electricity a motor system uses. In order to achieve these savings, plant managers need appropriate information to match VFDs to the motor system application.

That’s where the fact sheet comes in handy. The following information is targeted to business decision makers as well as staff at other levels. It simplifies what could be a complex decision given competing business priorities, by laying out the situations in which VFDs are most beneficial. For facilities that move air or water, it’s worth the time to take a look at this fact sheet and assess the costs and benefits of VFDs.

MODERNIZE YOUR MOTOR SYSTEMS

Running motors at full speed when it’s not required is a waste of energy and money. A variable frequency drive is a widely used device that reduces motor speed to match a driven load by controlling the frequency (Hz) and Volts/Hz ratio supplied to the motor.

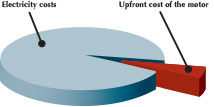

SHRINK THE ELECTRICITY PIE

A whopping 95 percent of the cost-of-ownership of a motor is the cost of electricity. When implemented correctly, VFDs reduce these costs and can provide other benefits as well. Improved process controls can bypass capability in an emergency or failure and also offer protection from overload currents. Other benefits include noise reduction and extended motor equipment life.

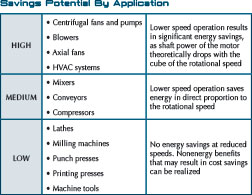

MATCH CORRECTLY TO ACHIEVE OPTIMAL SAVINGS

A variable frequency drive must be paired correctly with existing equipment in order to achieve optimal electricity savings. Generally, VFDs have lower savings potential in applications that require constant torque and constant speed. Lower savings potential also exists for high static pressure installations and soft start only applications.

GETTING STARTED

Many operations managers are unaware that some utilities offer technical and financial assistance for variable frequency drives on fans and pumps used in HVAC, chillers, pumps, and many other applications. A good next step would be for prospective users to ask their local utility, motor service center, or motor distributor to help identify opportunities for VFDs in their plant or facility. Online resources, such as those found on the MDM website (www.motorsmatter.org) can also provide VFD case studies, assessment tools, and links to utility programs throughout the United States and Canada.

Many market segments are already benefiting from the energy and cost savings of variable frequency drive technology. The range of applications include all aspects of the economy and all types of users. VFDs can be found at work in commercial buildings, food processing, grocery stores, cold storage, hospitals, schools and universities, industrial processes, water and wastewater treatment, and irrigation. For any facility routinely moves air or water, it is worth the time to assess the costs and benefits of installing a VFD.

CASE IN POINT: LAYFIELD GROUP

Layfield Group, a large plastic manufacturer, worked with utility BC Hydro in 2012 to improve the efficiency of its facilities. Using a BC Hydro incentive program, Layfield Group replaced several single-speed air compressors with one variable frequency drive model. The VFD model was projected to save 120,000 kWh of energy and about $7400 per year.

CONCLUSION

Managing a plant requires multiple decisions to achieve business goals. Optimizing motor systems to reduce costs is just one of them, but considering appropriate use of VFDs can significantly reduce costs. Many utilities throughout the US and Canada offer financial incentives to end users who install these devices to improve the efficiency of motor-driven systems. ■

For More Information

Walker Larsen is CEE’s industrial program manager and can be reached at wlarsen@cee1.org. Motor Decisions MatterSM is a sponsored project of the Consortium for Energy Efficiency. Email questions to mdminfo@cee1.org, and visit the Motor Decisions Matter website at www.motorsmatter.org to see other fact sheets, read case studies, or learn more about how VFDs can help boost your bottom line.

MODERN PUMPING TODAY, January 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!