By Chris Brand, ABB

Oman Cement Company (OCC) has built on a long-term ABB relationship with the installation of state-of-the-art digital solutions. ABB Ability™ System 800xA will optimize performance on all three process lines as OCC continues to supply the country’s construction industry. ABB has built on a forty-year relationship with leading cement producer Oman Cement Company SAOG in delivering the latest digital control systems to boost operational efficiency, increase availability, lower costs, and drive sustainability.

HEAVY WORK

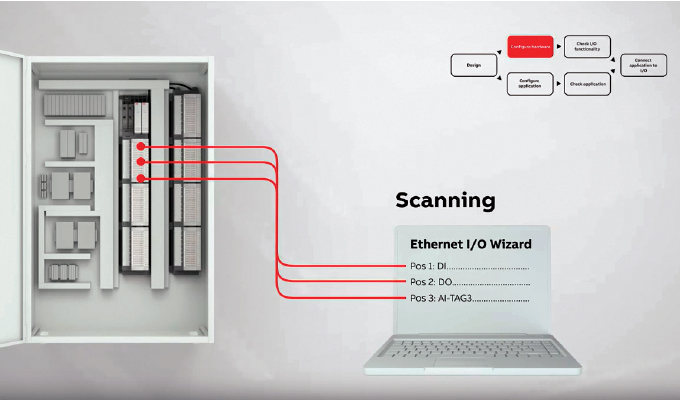

The Muscat-based cement factory, which has an annual cement production of 3.8 million tons, now has the latest version of ABB Ability System 800xA, which integrates its three process lines into the single digital platform. ABB has also replaced older controllers in their final lifecycle phase with AC800M models.

Teams from Oman Cement Company and ABB Switzerland collaborated to complete the engineering, supply, installation, and commissioning of the ABB systems. ABB secured two separate contracts for the work with OCC, a company that has been a customer since 1978.

“Cement production is a core industry for Oman, serving and enabling a self-sufficient construction industry,” says Bashar Al Farsi, head of instrumentation and control, OCC. “With the long-term support of ABB, we have added to this strength and look forward to continued success, now with the latest digital control system across our three process lines. We have already identified time and cost savings, and will drive towards greater efficiencies and sustainability targets as we aim to be the number one cement manufacturing company in the Sultanate.”

RANKED THE BEST

ABB Ability System 800xA, ranked by the ARC advisory group as the world’s top distributed control system (DCS) platform over the last twenty years, can implement advanced process control methods.

“Connecting all three lines on one platform from a single partner versus multiple deliveries from different parties harmonizes the engineering and technology standards across the plant. This also helps gain synergies for operations and maintenance teams by ensuring overall interoperability and consistency as well as reducing complexity,” says Max Tschurtschenthaler, global cement lead, ABB Process Industries.

BUILT FOR THE FUTURE

ABB’s new system also has a solid foundation to build up digital applications and integrate other process areas of the OCC plant on the same single platform.

“Deep domain knowledge and long-term customer relationships remain key factors of our performance and this was shown with our recent project with Oman Cement Company,” says Ramzi Akkawi, regional sales manager North Africa and Middle East for mining, aluminum, and cement, ABB.

“Clear technical know-how, upfront transparency and the ability to highlight and eliminate potential risks based on past execution experience was highly regarded by our customer. We had a strategic approach to execute these projects with minimal production downtime.”

FOR MORE INFORMATION

ABB is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries For more information, visit www.ability.abb.com.

MODERN PUMPING TODAY, March 2021

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!