By Raymond Buchanan, Weir

The CBMM, or Companhia Brasileira de Metalurgia e Mineração, is the global leader in the production and commercialization of Niobium products. CBMM has more than 400 customers, in more than forty countries. Headquartered in Brazil, with offices and subsidiaries in China, the Netherlands, Singapore, Switzerland, and the United States, the company supplies cutting-edge products and technology to the infrastructure, mobility, aerospace, and energy sectors.

Founded in 1955, in Araxá, Minas Gerais, Brazil, CBMM has a technology program that expands Niobium applications and contributes to the growth and diversification of this market. The reserves of the Araxá mines are measured and quantified for more than 100 years of operation, along the lines of current consumption.

THE CHALLENGE

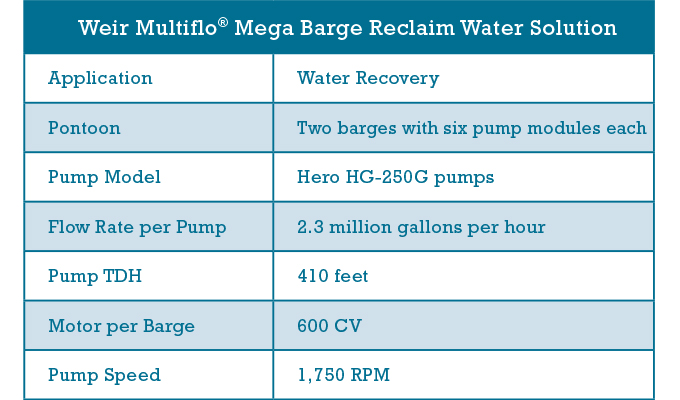

As part of CBMM’s production expansion plan they needed to install a new tailings dam on site, which was located inside a canyon. As a trusted partner, Weir Minerals was invited to design a water solution collection and transfer system capable of extracting 2.3 million gallons of water per hour. The complete solution needed to include 656-foot-long walkaways, discharge pipelines, electrical control system, mooring and anchoring system, and all safety requirements.

This pumping solution was essential to the customer in order to ensure the water level in the dam was kept to a minimum, thus increasing the dam’s wear-life, and avoiding risks as liquefaction, collapses, or earth contamination. The recovered water is used in the process and minimize the need for “fresh” make-up from other water source.

In addition to the large scale of the project, the water level in the dam was going to rise on a frequent basis. This required the pump operating conditions be automated to accommodate the changing discharge head requirements. Subsequently Weir Minerals Brazil designed and supplied an electrical control system that would a utomating adjust for the changing discharge head conditions.

Another critical component was to develop a long-term flexible, custom mooring and anchoring system to accommodate the floating pumping system.

THE SOLUTION

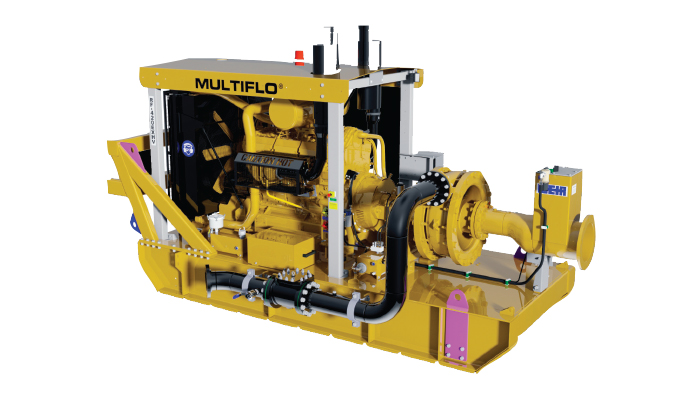

The Weir Minerals team provided a Weir Multiflo® mega barge water reclaim solution that included two barge clusters comprising of six floating pontoon modules each. Each of the pontoon modules were fitted with a single Hero HG 250G dewatering pump installed on an angle to allow for self-priming.

To achieve the goal of 2.3 million gallons per hour, the final pump solution was based on a parallel pumping pontoon system configuration that allows for ten operating units and two units on standby.

To ensure that the proposed solution was the best possible for the application, the Weir Minerals team evaluated the solution taking into consideration multiple factors such as: energy consumption, water level variation, TDH reduction, flow rate control, vibration, bearing house temperature variances, mooring analysis, hydraulic transient analysis, naval engineering as stability, fluctuation level, and complete structural analysis.

Additional effort was made to ensure the pump system operated at the optimal NPSH point: optimal power consumption and optimal variable frequency drive (VFD). The team also considered future design changes, such as when the operating level of the tailings pond rises and the discharge head on the pump system reduces. Therefore, to allow the pumping system to continue to operate at an optimal it was determined that it would be advisable to exchange the original impeller with a different design. Returning the pump system back into original high efficiency operating point.

In the future, when the water level of the dam rises, the installed equipment can be easily modified, saving energy and improving the flowrate.

THE RESULTS

Weir Minerals Brazil was directly involved with the entire scope of this project. From the initial conceptual detailed design; equipment fabrication, supply, onsite assembly, and commissioning process. In conjunction with the customer Weir Minerals Brazil determined the most effective solution was to assemble the equipment during the construction phase of the new B8 Tailings dam.

Multiflo mega barge water reclaim solution system has been operational since December 2018 and operating within the design parameters determined for this project. With this solution the CBMM Araxá plant can increase the operational capacity, recovering the water from the B8 Tailings Dam in a safety and sustainable way to keep our customers operations running.

FOR MORE INFORMATION

Combining ruggedness and flexibility, Weir’s Multiflo range includes skid base and trailer to single, double, and triple mounted pontoon pumps and heavy-duty barges constructed in a range of materials including steel, MDPE, and fiberglass. With diesel, electric, or hydraulic driven options, Weir can create the perfect dewatering configuration to meet customer needs. For more information, visit www.global.weir.

MODERN PUMPING TODAY, February 2021

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!