Burra Foods is a leading Australian dairy ingredient processor, producing value-added dairy products for the global food manufacturing market. An upgrade at their processing plant in Korumburra in the state of Victoria necessitated the use of a heat exchanger to warm frozen milk products, but existing building and infrastructure meant that the available space was severely limited.

TOUGH DEMANDS

The line in question produces skimmed milk concentrate and cream from frozen concentrates that are then thermalized and cooled to ambient processing temperatures. The required heat exchangers needed to raise the temperature of the product from 23 to 65 degrees Fahrenheit (-5 to 18 degrees Celsius) prior to the final heater, which includes melting the frozen product. After this the product is then cooled from 50 to 41 degrees Fahrenheit (10 to 5 degrees Celsius) in the final cooler.

Due to the consistency of the skimmed milk concentrate and cream the product is quite viscous, so the heat exchanger needed to resist fouling and provide good heat transfer performance, while also integrating with the plate heat exchangers used in the process in a very limited footprint.

FINDING A SOLUTION

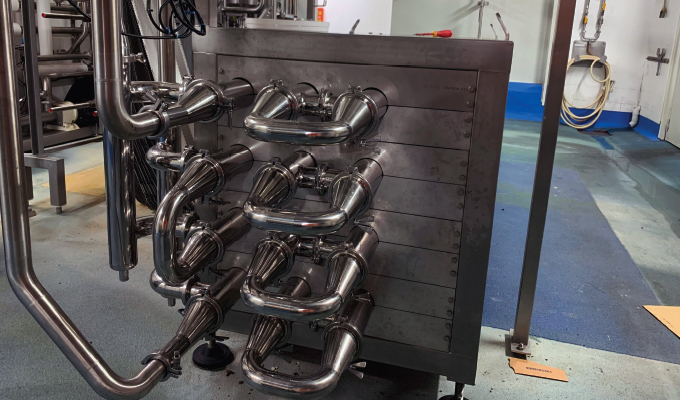

The solution was an HRS MI Series corrugated tube heat exchanger, which provided the necessary heating and cooling requirements in the tight space available and also resulting in a small pressure drop, another important consideration for this installation. Following an initial enquiry at the end of 2019, the unit was installed in mid-2020, and has exceeded performance expectations since final commissioning, with a production capacity of 11,000 pounds of product per hour.

Stuart Shattock, process engineering manager at Burra Foods, comments, “Other suppliers couldn’t match HRS’s offering in terms of tubular heat exchangers and the level of detail provided. Once we placed the order, there was a slight delay due to Covid, but HRS managed to produce it as a rush order and the installation and commissioning was really smooth. In fact, they were able to accommodate a change to the process design partway through installation and make some improvements on the fly, which is great for a nimble and flexible food and beverage business like ourselves.

“There are two parts to the unit: the heater and the cooler. The heater has performed well and done exactly what we expected, while the cooler has actually done more than we expected. Overall, we are very happy with the product and the output from it.”

SMALL FOOTPRINT, BIG PERFORMANCE

Chris Little, HRS Heat Exchangers’ Australian director, adds, “HRS’s corrugated tube heat exchanger technology was required in order to prevent fouling from the thick cream element of the product. The requirement for a heat exchanger with a small physical footprint meant that coming up with the final design was a challenge, but our engineering team rose to the occasion and provided a reliable solution which meets all of Burra Foods’ needs.”

FOR MORE INFORMATION

Located in Atlanta, Georgia, the company is part of the HRS Group, which operates at the forefront of thermal technology, offering innovative heat transfer solutions worldwide across a diverse range of industries. With forty years’ experience in the food and beverage sector, specializing in the design and manufacture of an extensive range of turnkey systems and components, incorporating its corrugated tubular and scraped surface heat exchanger technology, HRS units are compliant with global design and industry standards. For more information, visit www.hrs-heatexchangers.com.

MODERN PUMPING TODAY, February 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!