Pump users are asking for greater efficiency and more integrated solutions from both their pumps and motors, and Grundfos constantly strives to make its pumps even more efficient and energy saving. Using state-of-the-art technology and cutting-edge design, Grundfos pumping solutions meet virtually all customer requirements for efficiency, reliability, and cost effectiveness.

SIMPLIFIED SOLUTION

First introduced at the 2014 AHR Expo, the Grundfos LCSE split-coupled end suction pumps are now available in the United States. Available in twenty-one different models, the fully integrated, intelligent LCSE pumping system features the MLE variable speed motor in ranges from 3 to 30 horsepower in 3500 revolutions per minute and 3 to 25 horsepower in 1800 revolutions per minute. Speed control pumps like the LCSE offer energy savings of up to 50 percent.

“Our integrated pump systems help our customers meet the energy challenge now by improving system performance and reducing lifecycle costs,” says David McLean, vice president of business development for Grundfos Commercial Buildings. “The intelligent MLE motor system greatly simplifies pump commissioning and startup for each of the models. As a pioneer of innovative pumping solutions, Grundfos is dedicated to developing the highest quality pumps and pumping systems while at the same time contributing to a better quality of life and a healthier environment.”

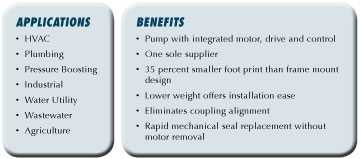

Ideally suited for new commercial HVAC/R applications and retrofits, the LCSE offers one sole supplier for pump, motor, and drive, resulting in reduced planning, purchasing, installation, wiring, and commissioning costs.

BENEFITS OF A SYSTEMS APPROACH

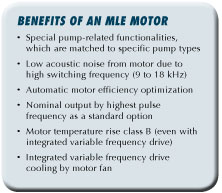

The LCSE offers a systems approach, which, through intelligent technology, adapts precisely to current demand to deliver performance, energy efficiency and reliability. The integrated, energy-optimized MLE system consists of a system controller, variable frequency drive (VFD) and standard asynchronous motor all in one, and can be fitted with loose sensors. Both are configured and interfaced at purchase, and their plug-and-pump design results in quick and easy installation.

GOOD TO GO

In addition, the LCSE features a footprint 35 percent smaller than that of a frame-mounted design. Its design allows for rapid mechanical seal access without motor removal. The unique design requires no baseplate grouting or coupling alignment in the field. The LCSE also features Grundfos GO technology, which allows building managers to remotely control and monitor the pump from a smart phone or tablet. The GO also facilitates installation and commissioning.

SAVINGS WHERE THEY COUNT

Power consumption accounts for 85 percent of all costs incurred during the life cycle of a pump—nine times more than the initial purchase price and cost of regular maintenance. Therefore, even the smallest improvement in efficiency can translate to sizeable savings. Grundfos LCSE split-coupled end suction pumps are the latest speed control pumps to enter the market and offer pump users a more efficient way to meet their needs.

About the Author

Helen Mubarak is the public affairs coordinator for Grundfos North America and can be reached at hmubarak@grundfos.com. With an annual production of more than 16 million pumps, Grundfos is the global leader in advanced pump solutions and a trendsetter in water technology, specializing in circulator pumps for heating and air conditioning as well as centrifugal pumps for industrial applications. Product CSI specifications, range charts, brochure, pricing, and selection of the products are available at www.grundfosexpresssuite.com.

MODERN PUMPING TODAY, August 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!