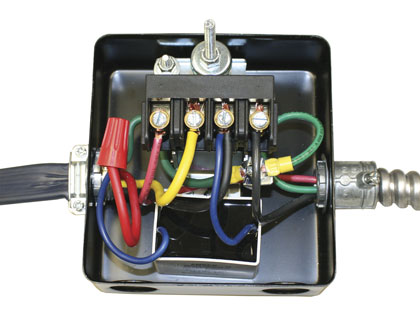

Last month, we introduced a solution for contractors looking for an option other than installing a traditional control box and pressure switch, running wires between them, and fitting all the connections in an undersized case. The newly designed Control Switch by Merrill Manufacturing, an Iowa-based water well/water system accessory manufacturer for the domestic, residential market, eliminates the added time to install and connect a pressure switch and a separate control box

SEEKING A FULL RANGE OF EQUIPMENT OPTIONS

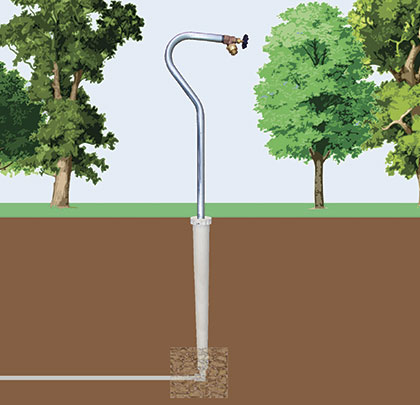

Another key area where many contractors require a full range of equipment options is in hydrant selection, due to significant variations in local climate, code and other factors. However, improvements in domestic water well devices are occurring here as well.

“To meet current Michigan code, we needed state-approved hydrants that do not drain back because these are no longer accepted,” says Chuck Garvie, a project manager at Brad Malley Well Drilling, a Michigan-based well drilling contractor and pump installer.

In this category of non-drain back hydrants, which help to meet municipal water codes and protect the underground well water supply, are devices with other useful features.

ENTER THE HIDE-DRANT

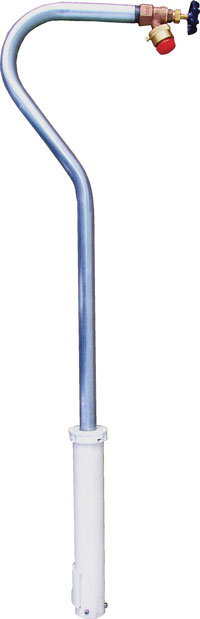

Garvie, for instance, selected a removable, sanitary yard hydrant called the Hide-Drant by Merrill. The company has one of the industry’s largest, most complete line of products to meet state or local well codes, with twenty-four series of yard hydrants, eight series of pitless products in all types, as well as splice kits, insert fittings, tank tees, and a full range of other water system accessories.

“The Hide-Drant meets Michigan state, municipal, and residential code,” says Garvie. “It is easy to install with no need for a double check backflow preventer or secondary line to be run with it. With a riser made of steel and a stainless steel connection, we have had virtually no callbacks. I installed one in my home and it still works well after twelve years with no problems.”

Since the sanitary yard hydrant’s insides are removable, users can easily connect one to the closest installed base for safe, convenient placement.

“At wells for RVs, campsites, or cabins, when people leave in the fall they can remove it to avoid freeze risk,” says Garvie. “At vacation properties, it can be removed to prevent vandals from running water in the owner’s absence, or it can be removed for easier mowing and then replaced.”

FIT FOR YEAR-ROUND SERVICE

For colder climates where all-year access to well water is required, additional innovations are available.

Nick Nawcewicz, a plumber at D&D Mechanical in North Dakota, for instance, has enjoyed success with the Any Temp Heated Hydrant. The device provides frost proof water service with a self-regulating heating cable that keeps water flowing, and drains itself below the frost line when shut off. It is often installed in mobile and manufactured homes, as well as livestock waterers in cold regions.

While some electrically powered heating cables in the industry are submerged below the water line and not grounded, the device’s heating cables are grounded and not placed under the water line.

“We have found that the Any Temp Heated Hydrant succeeds anywhere heated well water is needed year-round,” says Nawcewicz. “The heated cables are kept dry outside of the pipe, so they are easy to install, replace, and do not have to be dug up. They are grounded and essentially trouble free. I have never had one trip out from ground faults.”

A few additional innovations that may pay off for contractors include: pitless adaptors and easy to install pitless kits; extra-long, electrical heat shrink tubing with a sealant and adhesive inside; stainless steel connectors at a price lower than no-lead brass; self-lubricating hydrant plungers that last over one million cycles; and variable speed pumps that vary depending on water demand.

AN EYE FOR DETAIL

For contractors needing to cost-effectively meet well codes and stay competitive, having access to a wider range of well equipment and accessories can further streamline their installation process. Paying attention to some of the smaller details in system design and product selection can help to optimize quality as well. ◆

For More Information:

Stephen Anderson is the president of Merrill Manufacturing and serves on various advisory boards and committees. Merrill Manufacturing manufactures and sells the industry’s largest selection of water well accessories and maintains membership in the Water Systems Council, National Ground Water Association, Water Well Trust, and numerous state water well associations. For more information, call 800.831.6962 or visit www.merrillmfg.com.

____________________________________________

MODERN PUMPING TODAY, October 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()