Municipal water plant engineers in a tight spot over cramped chlorine system equipment areas will find the Model ST100L Air/Gas In-Line Thermal Mass Flow Meter with Vortab® Flow Conditioner from Fluid Components International (FCI) provides accurate flow measurement without the long straight pipe runs required by other meters.

SAFETY FIRST

In order to provide a safe source of clean drinking water, all municipal water system operators rely on a disinfection system to kill germs. There are several different methods of disinfection treatment, such as chlorine and ozone, but chlorine remains a popular disinfectant around the world. Where chlorine systems are in use, accurate chlorine gas measurement is essential for disinfection and safe operation of the system.

The successful measurement of chlorine presents a challenge for flow meter suppliers. Due to safety hazard regulations, flow meter manufacturers cannot flow chlorine gas at their facilities to calibrate chlorine gas flow meters accurately. Furthermore, research has shown that the theoretical “air equivalency” calibrations for chlorine gas are inaccurate and inadequate. To address this problem, certified FCI field technicians perform on-site calibration adjustments to match the site specific installation.

Featured Image: ST100L Flow Meter utilizes constant power.

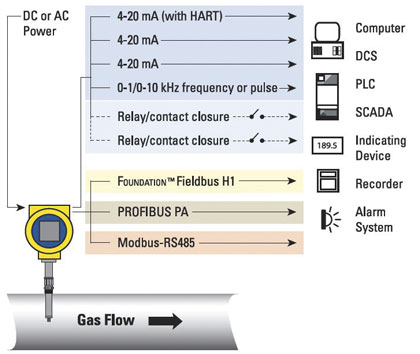

Above: The ST100L offers various output options..

ACCURATE, REPEATABLE MEASUREMENT

The Model ST100L is an in-line, spool piece gas mass flow meter suitable for chlorine gas service and is available with an optional built-in Vortab Flow Conditioner. This inline model is designed specifically for line sizes of 1, 1.5, or 2 inches [DN25, DN40 or DN50], and the optional built-in flow conditioner overcomes any lack of available straight-run pipe in the installation. The meter’s Vortab flow conditioner eliminates both swirl and profile disturbances throughout the full flow range, including transitional region, to produce a repeatable flow profile for accurate, highly repeatable flow measurement.

The ST100L Flow Meter is typically installed in a water disinfection system’s chlorine gas inlet line to the chlorinator panel. For operation in corrosive chlorine gas environments, this meter’s wetted material, including sensor element, inline flow body, flow conditioner, and process connections, are all fabricated of Hastelloy C-276 to ensure their corrosion protection and long life.

MATCHING THE METER TO THE APPLICATION

When selecting the ST100L Flow Meter, users have multiple communication options: 4-20 mA analog, frequency/pulse, or certified digital bus communications such as HART, Foundation Fieldbus, Profibus PA, or Modbus RS485. Should a water plant’s communication need change, so can the ST100L meter with field or factory replacement of the output circuit board.

Developed with a graphical, multivariable backlit LCD display, the ST100L Flow Meter brings new meaning to the term “process information.” Its sophisticated readout continuously displays all process measurements and alarm status for easy on-site viewing by technicians, and it has the ability to query for service diagnostics.

The feature-rich ST100L Flow Meter utilizes constant power thermal mass flow sensing technology that measure flow with 100:1 turndown in ranges from 0.006 to 1850 SCFM [0.01 to 3140 NCMH]. The transmitter/electronics can be integrally mounted with the flow body or may be remote mounted to 1000 feet away. The transmitter enclosure is NEMA4X/IP67 rated and available in painted aluminum or stainless steel. ◆

Fluid Components International is a global company committed to meeting the needs of its customers through innovative solutions for the most challenging requirements for sensing and measuring flow, pressure, and temperature of gases. For more information, call 760.744.6950, email fcimarcom@fluidcomponents.com, or visit www.fluidcomponents.com.

____________________________________________

MODERN PUMPING TODAY, September 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()