In most scenarios, preventive maintenance is a more cost- and time-effective solution to increase efficiency rather than waiting for it to fail and having to stop operations to repair or replace the broken piece. The latter requires the company to accrue downtime and make expensive repairs, costing the company thousands, if not millions, of dollars. This holds true for all types of pumps.

While there are many different types of pumps, the same principles apply to all of them: pumps are spinning objects that create vibration and are designed to be in balance. Data monitors and receivers can record these micro-movements and put them into a profile to track the vibrations and establish a baseline. Once this profile is complete, it is easy to see when vibrations change. When there are dramatic or small, but consistent, deviations, it is a safe assumption that something along the pipeline is no longer balanced and is in need of a quick repair for operational efficiency and to reduce waste.

IN NEED OF REPAIR

Creating these profiles is especially important in the oil and gas industry, and even more so in the fracking division. SpotSee is working with one fracking company in particular to reduce its downtime and increase its productivity through the company’s pumps and valves while fracking.

When the client is preparing to run its fracking system, trucks line up and connect their pumps together in order to move the water and frack sand down the well at a pressure of 8,000 to 10,000 psi. Not surprisingly, the extreme pressure on the valves inside the pumps causes wear and tear quickly and increases the frequency at which they need to be repaired. Without repairs, the pumps begin to leak, creating blowback and waste. Additionally, the repairs become more costly the longer the company waits to take action.

REDUCING DOWNTIME AND COSTS

Prior to working with SpotSee, the company knew it did not take long to wear out a valve in a pump while fracking, but it did not necessarily know which valve was failing or when was the correct time to change the valve. Thus, if the company would change the valves too early, when the valves were still working adequately the company would waste extra money on valves. If the company replaced the valves too late, the valves were already costing the company its efficiency. The company wanted to know when and where valves were failing, but was not sure how to solve the issue.

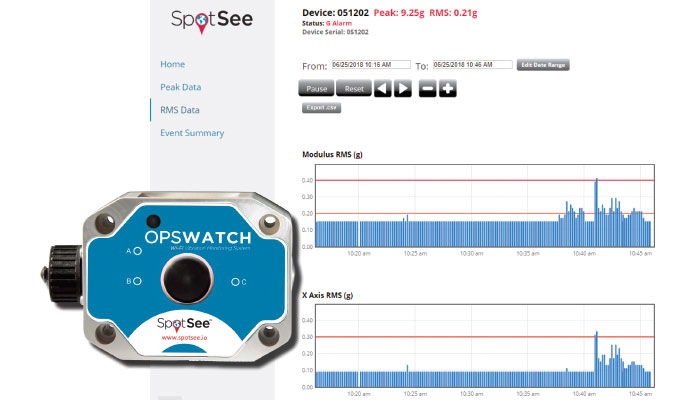

That is where SpotSee’s OpsWatch came into play. The device is built for heavy, industrial environments, and senses vibrations and imbalances to prevent catastrophic failures. Using local power, OpsWatch connects to each piece of equipment that is spinning or reciprocating to monitor vibrations in real time and visualizes changes to the pumps’ vibration levels. This enables the technology to identify when deviations occur.

POWER SPECTRAL DENSITY

This real-time data is sent to the SpotSee Cloud where mathematical models—called power spectral density—create baselines for when the pump is performing as it should and alerts for when something changes. The software runs the data and notifies the users of changes in vibrations at the time of the event. These changes serve as an early warning of a decline in operating function and signals the need for preventive maintenance to avoid more serious damage. Without this data and the models, the valves and pumps could unknowingly spring a leak, garnering a 20 percent loss or more. It could also cause the entire pump to go down, forcing production to cease while more expensive repairs are made. OpsWatch senses these potentially catastrophic changes and then is able to prevent this from happening, reducing overall downtime for maintenance and repairs.

BENEFITS GOING FORWARD

While this application of OpsWatch is currently in the testing phase, early indications are positive and the fracking company expects to see high returns on its investment by not having to lose as much material, spend more money replacing equipment, and waste downtime. And, since this fracking company competes with other companies to secure frack jobs, the application of SpotSee’s OpsWatch sets the client up with a differentiator that will ultimately save the well operator money as well. If the fracking company is able to consistently and efficiently pump water and frack sand down a well, then the well can become operational at a faster rate. If the well is operational sooner, then the well can reduce its downtime and begin production again in less time.

This same method of monitoring vibrations can be applied to all types of pumps, and should be applied to a wide variety of equipment to reduce downtime and save companies from going through a failure that could lead to even larger issues in the overall business model.

ABOUT THE AUTHOR

Clint Branch is a senior product engineering leader for SpotSee, the global leader in shock, vibration, and temperature monitoring through low-cost connectivity and data. He is a technically sophisticated and team-oriented engineering professional with a track record of growth in high-tech product design, engineering, and manufacturing. Brach has developed sixty-two market-tested products and holds twenty-four patents—fifteen in the U.S. and nine internationally. For more information, visit www.spotsee.io.

_______________________________________________________

MODERN PUMPING TODAY, October 2018

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()