People love to dine out, but there’s a dark side to restaurant cooking. Along with refuse from animal product cooking and processing, it forms a thick, heavy mess in our nation’s sewers referred to as FOG—fats, oil, and grease. This substance is undeniably a nightmare for municipalities and waste haulers alike. Publicly owned wastewater treatment plants, many already facing the aging out of their infrastructure and pressure from growing populations beyond what they were designed to serve, do not have enough capacity to process it all.

OUR LONG, NATIONAL NIGHTMARE IS JUST BEGINNING

Desperate to stay within compliance for effluent quality, they’ve been forced to begin turning away haulers who want to dispose of restaurant and animal product processor loads. Not only is this causing hardship for these haulers and processors, it’s causing revenue loss for the treatment plants from lost tipping fees.

Even without FOG entering plants from haulers, the amount of it already in sewer systems from overflowing grease traps, faulty interceptors, and residents and businesses just pouring grease and oil down their kitchen drains, is at best straining treatment capacity. At worst, it’s crippling the ability of smaller, older facilities (and even some newer ones) to remain compliant with environmental regulations for things such as SSOs and effluent quality.

The need to clean FOG from those sewer systems’ infrastructure is taxing the resources—labor, equipment, and funding—of every collection and conveyance system operator. Even the most carefully managed plants will eventually have to institute ratepayer hikes, which will have a detrimental effect on public goodwill, and possibly even political ramifications.

A SOLUTION IN SIGHT

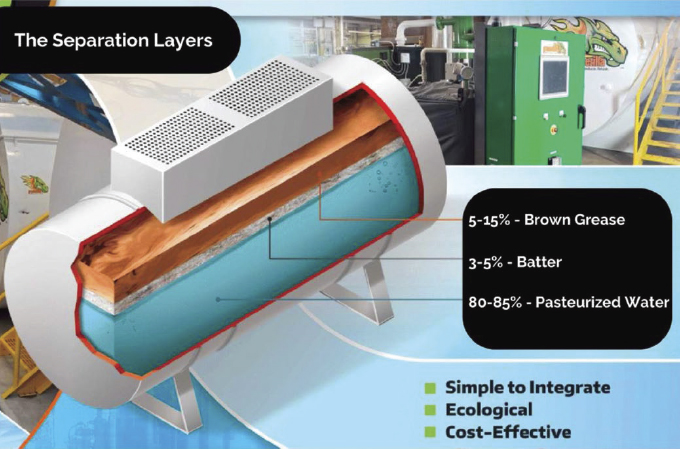

Greasezilla is a revolutionary hydronic-thermal separation system that ecologically processes FOG into three components: brown grease advanced biofuel (ABF) feedstock; batter for composting and anaerobic digester feedstock; and pasteurized water, which can safely return to the sanitary waste stream. Unlike traditional processes, Greasezilla fully recovers the energy resources of the waste stream, leaving nominal waste to be landfilled, and requiring no chemicals or additives. This makes Greasezilla ABF what we call the “roundest fuel,” a solution most fully embodying the tenets of a completely closed/no waste reuse cycle.

By creating their own FOG separation station, wastewater treatment plants can not only solve their own FOG woes, but also create a new revenue stream by providing a desperately needed new disposal option for haulers that won’t put undue pressure on their waste streams.

With such FOG pre-treatment in place, municipalities will effectively create higher overall treatment capacity, without having to physically expand their plants. It also provides a way to process the massive deposits of FOG—often referred to as “fatbergs”—cleaned from their collection system’s infrastructure.

EASY TO INSTALL

Greasezilla’s system footprint is a mere 1,000 square feet. Depending on available space, the system is scalable to accommodate any volume, making it the centerpiece of a wastewater treatment plant’s onsite FOG receiving station. A standard two-reactor tank system processes six to seven million gallons of FOG waste per year. Greasezilla supplies and installs complete turnkey systems and can build, own and operate them for cities, as well.

The versatile system can be installed and operated outside in warm-weather locations, with cold-weather locations finding much more ease of operation inside a building. It is also amazingly efficient and cost-effective. Running on the brown grease biofuel it creates, it’s largely self-sustaining, energy-wise. And because it does not require dewatered material, Greasezilla can replace dated dewatering facilities.

PAYS FOR ITSELF WITH A SUSTAINABLE BIOPRODUCT

Aside from being able to reinstate hauler tipping fees, wastewater treatment plants can turn the nightmare of FOG into another new revenue stream, by selling the end product of the Greasezilla FOG separation process: Brown grease ABF. The convergence of waste reduction initiatives, low-carbon biofuel demand, tightening emissions regulations, and environmental sustainability goals have created unprecedented demand for such renewable fuel feedstocks.

This demand will only continue to grow, due to brown grease ABF’s versatility as a vital feedstock in the production and consumption of biodiesel, renewable diesel, sustainable aviation and marine fuels. Since Greasezilla produces this feedstock, it turns a former waste material from something that clogs landfills and produces the notorious greenhouse gas, methane, into a clean, saleable, renewable resource that will augment current revenue streams for wastewater treatment facilities.

Understanding that not every municipality or plant operator is set up to sell byproducts of their facilities, the manufacturer guarantees the sale of produced brown grease ABF at fair market prices for plants that want that assurance, as well.

FROM LIABILITY TO ASSET

The EPA recently added feedstocks to the Renewable Fuel Standards RIN-qualified pathways. This makes Greasezilla’s ABF now eligible for low-carbon fuel credits and RINs, creating another potential revenue stream from the sale of RIN and LCFC credits.

FOG can now realistically be turned from a crippling fiscal and physical problem into a new revenue producer for publicly owned wastewater treatment plants, by creating a FOG receiving station around such technology.

FOR MORE INFORMATION

Greasezilla provides services and technology that significantly reduce or eliminate costs associated with dewatering, drying, lagooning, land applying, composting, incinerating, hauling, tipping, or any further treatment of wastewater and grease trap output. In the process, Greasezilla creates a biofuel feedstock sold on commodity exchanges for competitive rates. For more information, visit www.greasezilla.com.

MODERN PUMPING TODAY, June 2024

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!