By Myra Mash, Emerson

AMS ASSET MONITOR

The AMS Asset Monitor manages pervasive sensing while providing prediction, protection, and process monitoring capabilities. It is designed to mount at the asset, reducing cabling requirements and other installation costs. It accommodates up to twelve CHARMs including Vibration as well as DeltaV CHARMs for process inputs. For larger systems, multiple units can be daisy-chained together to extend the asset coverage. This monitor features an internal Logic Studio with multiple pre-programmed application solutions for easy-to-understand analysis and alert reporting. The AMS Asset Monitor can be configured to send overall asset health status and alerts to Emerson’s Plantweb Optics asset performance platform and detailed asset data by OPC UA. Detailed asset information is also available on a user’s mobile device or desktop thin client from the monitors internal web-served Asset Studio interface.

Plants around the globe have faced increasing shortages of experienced personnel to monitor and manage equipment reliability. Today, 58 percent of multinational manufacturers are having difficulty acquiring skilled talent according to a 2021 study from Workforce Institute at Ultimate Kronos Group. To help small teams make the most of limited resources, Emerson has continuously evolved AMS Machine Works’ condition monitoring technologies for better diagnostics at the industrial edge.

CREATING NEW SOLUTIONS

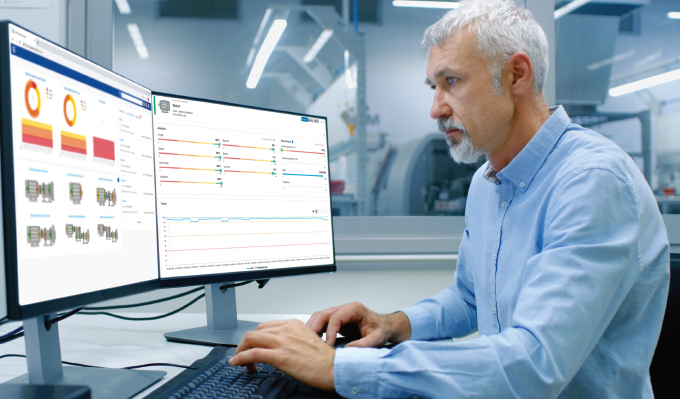

Global software and technology leader Emerson is updating its machinery health platform to enable customers to migrate to a more holistic, modern interface for condition monitoring. New support brings data from edge analytics devices directly to key personnel inside and outside the control room to help them more quickly identify and address a wide range of common equipment faults before they impact plant availability. In some industries, Emerson estimates every 1 percent gain in availability is worth approximately $8.4 million of additional profit margin per year.

Increased connectivity to external systems provides personnel with an intuitive, holistic asset health score supported by maintenance recommendations to help reliability teams quickly see what is wrong and how to fix it. Intuitive information and alerts are delivered directly to workstations or mobile devices to provide decision support, helping maintenance personnel make the best use of their time.

“As smaller groups of experienced reliability personnel are tasked with supporting an increasing scope of work, they need access to immediate insights and faster, more comprehensive information to prevent downtime and keep plants running at peak performance,” says Erik Lindhjem, vice president of reliability solutions at Emerson.

CLOSING THE LOOP ON PLANT SUPPORT

The newest version of AMS Machine Works adds support for Emerson’s AMS Asset Monitor, which provides embedded, automatic analytics at the edge using patented PeakVue technology to alert personnel to the most common faults associated with a wide range of assets.

“The newest version of AMS Machine Works seamlessly interfaces with edge analytics devices to help teams of any size stay aware of the health of all plant production assets, from critical to balance-of-plant, no matter where they may be,” Lindhjem adds.

AMS Machine Works also supports open connectivity using the OPC UA protocol to make it easier to connect to external systems such as historians, computerized maintenance management systems, and more to help close the loop on plant support from identification to repair and documentation.

Emerson, headquartered in St. Louis, Missouri, is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Emerson’s Automation Solutions business helps process, hybrid, and discrete manufacturers maximize production, protect personnel, and the environment while optimizing their energy and operating costs. Emerson’s Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure.For more information, visit www.emerson.com.

MODERN PUMPING TODAY, June 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!