It’s one thing to promise reliable performance under hazardous and demanding conditions, but what happens when a product is put to the test? A prominent industrial entity in South Korea carried out testing on Vesconite Bearings’ Hitemp 160 machined bushings by fully submerging the bushings in an oleum (fuming sulfuric acid at 30 percent concentration) up to a temperature of 176 degrees Fahrenheit (80 degrees Celsius) while utilizing an alloy 20 stainless steel shaft on a sump pump. Even under the conditions of this demanding application, the customer was pleased with the material’s success.

PASSING THE TEST

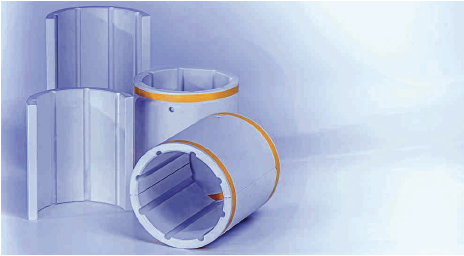

The test results have been gratifying, reaffirming Vesconite Bearings’ commitment to providing reliable and durable solutions for challenging environments. The Hitemp 160 machined bushings, developed to have good resistance to extreme chemicals and high temperatures in bearing applications, have proven their worth in this demanding application.

Both the company and manufacturer were thrilled with the performance of the Hitemp160 machined bushings in the recent testing conducted in South Korea, which further reinforces Vesconite Bearings’ position as a leading provider of high-quality engineered bearing and wear materials for critical applications in challenging environments.

REAPING THE REWARDS

Due to the resounding success of the testing, the client has expressed its confidence in Vesconite Bearings’ products by placing an immediate order for an additional set of three Hitemp160 machined bushings.

The repeat order underscores the client’s satisfaction with the product’s performance and its trust in Vesconite Bearings’ ability to deliver reliable solutions to meet its industrial needs, and in short delivery time frames.

Vesconite Bearings takes pride in its commitment to customer satisfaction and continuous improvement, striving to develop innovative, high-performance solutions that withstand the most demanding operating conditions.

SUCCESS BREEDS SUCCESS

The successful testing in South Korea is a testament to Vesconite Bearings’ dedication to providing reliable and durable products for numerous applications across various industries around the globe. Just in the last year, the Water Regulations Approval Scheme (WRAS), an independent certification body for plumbing products and materials in the United Kingdom, approved Hitemp 160 bearing material for contact with water up to 150 degrees Fahrenheit (65 degrees Celsius).

With the certification, the material is certified as safe for water intended for human consumption up until that high temperature. U.K. pump and potable water component manufacturers can confidently use the product within the given temperature parameters, and the certification also provides comfort for the general safety of the bearing material where it is used outside of the United Kingdom.

FOR MORE INFORMATION

Phillip de Villiers is senior technical representative at Vesconite Bearings. Vesconite Bearings is a world-leading manufacturer of low-friction, low-wear bearing materials for a wide range of industries. Selling to over 100 countries, these include the pump, agriculture, railways, mining, heavy transport, hydro, renewable-energy, earthmoving, marine, and construction industries. For more information, visit www.vesconite.com.

MODERN PUMPING TODAY, October 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!