Delta Sand and Gravel Co., located in Eugene, Oregon, has been providing quality aggregate materials, service and expertise for almost nine decades. The company offers a full line of aggregate products for year-round, all-weather construction and demolition landfill. Xylem has partnered with Delta Sand and Gravel for over a decade to provide holistic water management solutions.

TAKING ON A CHALLENGE

Delta Sand and Gravel has a central collection pit to handle all surface water from across its operations. The surface water is pumped to a series of five settling ponds before being safely discharged into the environment or re-used on-site. The three permanently-installed pumps, which had been in place for many years, were inefficient, and experienced frequent maintenance issues.

The in-rush current at startup was also problematic, adding to maintenance problems and risking surges that could impact the surrounding power grid. Repairs on the pumps were costly and cumbersome, with a crane required to lift the pumps out of the pit. In addition, parts were becoming difficult to source, due to the age of the pumps.

With plans to increase the depth of the pit by 100 feet in the coming years, Delta needed a robust, efficient and flexible pumping solution. The company had rented Dri-Prime diesel-driven and submersible pumps from Xylem previously, and they turned to us again to solve this latest challenge.

THE GOULDS SOLUTION

Enhancing pumping efficiency and resiliency at this sand and gravel operation was a top priority. One of the permanently-installed pumps in the collection pit runs 24/7, with all three pumps running simultaneously at certain times of the year when rainfall is high. Xylem recommended a turn-key solution, incorporating its Goulds Water Technology vertical turbine pumps as a highly efficient, reliable, and easy-to-operate solution.

The pumps are equipped with variable frequency drives (VFDs) to optimize energy consumption, while a soft start controller facilitates a slow ramp up and addresses the large in-rush current issue. Add to this the flexibility of the pump model, which means the pumps will continue to operate at best efficiency point (BEP), even when the pit is lowered by 100 feet in the coming years.

A ROBUST RESULT

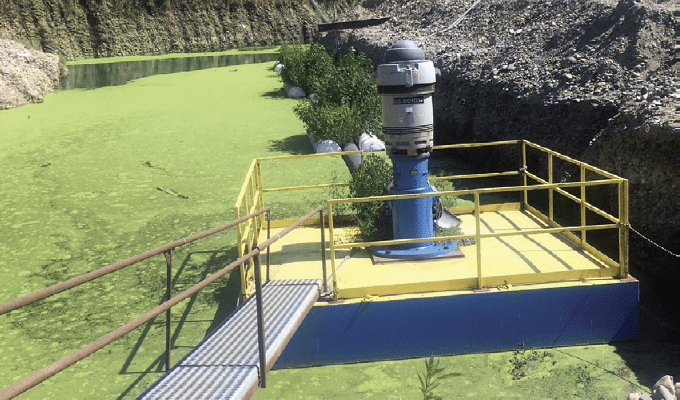

Xylem’s turn-key solution includes pumps, a floating barge, and a robust suction screen—a comprehensive solution from a single provider to support the mine’s needs today and tomorrow. In addition to the first pump system, two new pumps are due to be operational ahead of the rainy season in fall. The robust, reliable solution resulted in a savings in energy consumption of 25 percent, compared to the old system.

The low-maintenance pump model will enhance safety at the plant, reducing the need to bring a crane and crew on-site when repairs are required, and will cut costs significantly as a result. The mine operators also have the peace of mind that the pump can be configured for optimal efficiency when they lower the pit in the future.

PROJECT SUMMARY

Project Highlights:

- Design and installation of a holistic, turn-key solution including vertical turbine pumps, a floating barge, and a robust suction screen

- Supporting enhanced site safety by removing the need for a crane and crew to perform regular maintenance

Solutions:

- Goulds Water Technology 18LHC Line Shaft Vertical Turbine Pump

- Equipped with 400-horsepower motor

- Customized robust suction screen

- Xylem engineered and fabricated floating barge for the pumps

Customer Benefits:

- Energy savings of 25 percent

- A flexible, reliable, and high-efficiency pumping solution that is configurable to current and future pit depths

- Enhanced operational efficiency and reliability

FOR MORE INFORMATION

Xylem is a global water technology provider helping our customers solve the world’s toughest water challenges across utility, industrial, commercial, and residential markets worldwide. Over the last 100-plus years, Xylem’s unique combination of innovative products and services, proven expertise, and unmatched customer support have been helping to create a more water-secure and resilient world. Across the water cycle, Xylem’s innovative solutions use less energy, reduce operating expenses, and support sustainability efforts. By working together, Xylem ensures water is accessible, affordable, and safe for all. For more information, visit www.xylem.com.

MODERN PUMPING TODAY, February 2024

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!