As a country Spain is well known for its cuisine, with iconic dishes such as paella, patatas bravas, tortilla, Serrano ham, and churros, all recognized and enjoyed around the world. Another famous dish, particularly associated with the southern region of Andalusia, is the cold tomato soup gazpacho. Although less familiar overseas than some of Spain’s other culinary exports, it is hugely popular in its home country.

From humble origins as a summer dish for local farmer and their families, gazpacho has gained popularity with both Spanish families and tourists thanks to its refreshing properties and distinctive fresh taste. As demand has grown, so has commercial production, with large scale modern production beginning in Murcia in the 1990s.

BOOST IN POPULARITY INCREASES PRODUCTION

Since then, more and more food and drink producers have added gazpacho to their product range. As well as large suppliers (often supplying heavily pasteurized product in large quantities), recently smaller companies have begun to bring more premium gazpacho and salmorejo products to market. Salmorejo, which has become particularly popular recently, is similar to gazpacho but thickened with bread, meaning it is eaten from a bowl using a spoon, while gazpacho is usually drunk as a cold soup. Most manufacturers of gazpacho now also produce salmorejo.

These premium gazpacho and salmorejo products are made using good quality fresh vegetables, with a minimum amount of processing, and are often sold as ‘unprocessed’ products, with a short shelf life and higher price, often in smaller plastic bottles which allow consumers to see the product on the shelf. Although 1-liter waxed card and PET bottles remain the most common packaging, larger formats for families, and smaller portions for people living alone or couples without children are also widely available.

RELIABLE PASTEURIZATION SOLUTIONS

HRS Heat Exchangers have been providing pasteurization solutions for gazpacho for almost thirty years (we supplied out first unit in 1996), as well as heat exchange solutions to help cool vegetables during the early stages of manufacture, and we have solutions for more viscous salmorejo products.

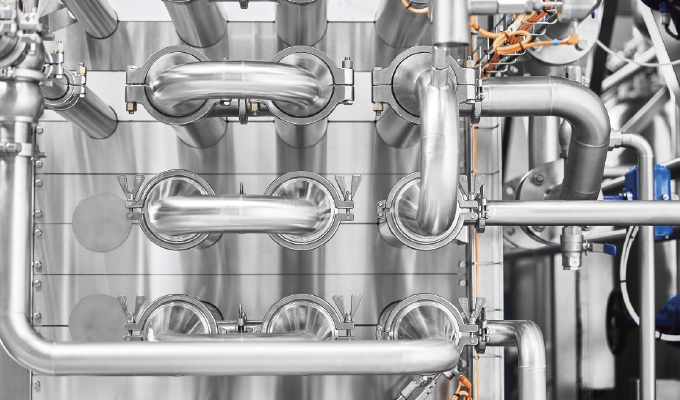

Because of their thick, viscous nature gazpacho and salmorejo require tubular heat exchangers—rather than plate heat exchangers (PHEs). Depending on the recipe they may contain content such as grains, bread or vegetable fibers (particularly those products designed to be ‘authentic’ or ‘homemade’). Most lines are now used to produce both gazpacho and salmorejo, so equipment needs to be flexible and able to handle the thicker products. In practice this means food grade HRS MI Series multi-tube heat exchanges, designed to maintain product freshness according to the required production capacity.

As a cold soup, keeping the distinctive freshness is a challenge, so any pasteurization process must be as gentle as possible. That means making it as fast as possible, with the lowest possible temperature lift, followed by immediate cooling. Pressure is typically maintained between 16 and 25 bar, although higher pressures may be required for salmorejo. This very small temperature gap is required to avoid overcooking the product, and the corrugated tube design of the HRS MI Series allows it to operate within these parameters.

GROWING FOR THE FUTURE

The market for salmorejo and gazpacho continues to grow, and HRS continues to work with key players in the market, including replacing older equipment which is not suitable for salmorejo with more flexible alternatives, supplying new pasteurizers to increase overall production capacity, and providing pasteurizing solutions for premium products which maintain the quality of small-batch, top quality brands while ensuring consistency and food safety for the consumer.

Francisco Hernández Ortiz is global food projects director for HRS Heat Exchangers. Located in Georgia, HRS Heat Exchangers is part of the EIL Group (Exchanger Industries Limited), which operates at the forefront of thermal technology. HRS offers innovative heat transfer solutions worldwide across a diverse range of industries. With more than forty years’ experience in the food and beverage sector, specializing in the design and manufacture of an extensive range of turnkey systems and components, incorporating our corrugated tubular, and scraped surface heat exchanger technology, HRS products are compliant with global design and industry standards. For more information, visit www.hrs-heatexchangers.com.