The LDT Dosatron proportional dosing system is used for the dosing of coolant lubricants and its innovative design significantly increases the energy efficiency of machine tools. Instead of an electric drive, the unit has a hydraulic motor and works without electricity. It can also be used in ATEX zones.

The German Machine Tool Builders’ Association (VDW) reported a 16 percent increase in the number of new orders within the German machine tool industry in the second quarter of 2016 compared to the same period in 2015. This means Germany continues to hold the third position worldwide for machine tool production. While foreign demand for German machine tools was up 14 percent, orders from within Germany grew by as much as 19 percent. This includes a growth rate of 2 percent for the area of machining.

In order to continue this positive growth in the future, innovative ideas are required to ensure the quality of German products. Energy efficiency and sustainability must also be considered here.

A range of drives and ancillary units for machine tools supports this continuous optimization. Nevertheless, the available options that increase energy efficiency do not always seem to be recognized. For example, the use of a non-electric LDT Dosatron proportional dosing system for coolant lubricant dosing is a simple way of significantly increasing energy efficiency.

HOW IT WORKS

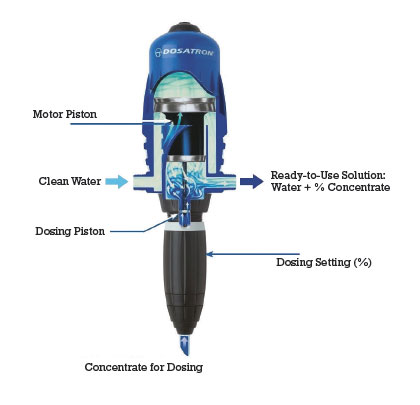

A proportional dosing system, e.g. LDT Dosatron, works with a volumetric hydraulic motor and enables the continual injection of the liquid or soluble concentrate. Connected to the water supply system, the Dosatron’s only driving force is the water pressure. The concentrate is drawn in independently and mixes with the drive water. The resulting solution flows through the Dosatron. The dosing quantity always stays proportional to the water throughput, as per the manually set dosing rate, even if there are throughput or pressure fluctuations in the water supply system. The pipe lengths have no effect on the dosing accuracy either, allowing the unit to be installed wherever required.

OPERATING PRINCIPLE

The proportional dosing system combines the functions of a water meter, dosing feeder, and mixer in a single unit. The continuous and immediate mixing in the dosing system’s mixing chamber is a special feature that ensures a homogeneous and ready-to-use solution for immediate use, e.g. for applying a cooling lubricant solution.

Depending on the particular unit, the performance range of the Dosatron proportional dosing system ranges from a maximum of 185 gallons per hour to 5,280 gallons per hour at operating pressures of 0.12 to 10 bar and a dosing rate of 0.03 percent to 25 percent.

The high dosing accuracy and reproducibility of +/- 3 percent (according to the API 675 standard) is an economic advantage for the operator, as more highly concentrated media can be used. The design does not allow overdosing to occur.

In addition to the economic arguments and advantages, the materials used also play a crucial role. To ensure high resistance against the dosing liquids, the dosing system housing is made from special polypropylene (polyacetal, HT). For highly concentrated, aggressive acids and bases, an optional housing made from PVDF can be used.

Available sealant materials include AF, a special Viton material, for alkaline concentrates, and VF, an EPDM-based material, for acids and oils. Kalrez seals are used for highly concentrated acids.

In addition to the various sealant materials chosen according to the dosing media, there are also other options available. These include, for example, an external injection of the dosing medium into the water stream, which is recommended for certain corrosive concentrates and polymers.

For highly viscous concentrates of greater than 400 cPs, a special kit is used, with the maximum concentrate viscosity being 800 cPs.

And for series D25 and D3, a bypass switch can be selected to switch the suction system on or off as required.

DOSATRON WITH PVDF HOUSING AND EXTERNAL INJECTION (IE)

Thanks to the simple design of the proportional dosing system with just a few components, the unit is very maintenance friendly and easy to handle. A wall holder for easy mounting and a suction tube are included in the scope of delivery.

PROPORTIONAL DOSING AND MIXING OF COOLING LUBRICANTS AND WATER

In the metal-working industry, cooling lubricant is used in nearly all machining tools and metal-working machines such as machining centres, lathes, drilling units, milling machines, etc. The cooling lubricants are delivered in concentrated form in barrels or containers and are diluted before use. Over time the levels of cooling lubricants in the machines decrease due to evaporation and loss via the metal cuttings, and so the levels need be refilled with the correct mixture ratio—this is where proportional dosing systems come into play.

COOLING LUBRICANT DOSING

Traditional coolant lubricant feeding systems which can still be found today range from manual machine loading, dosing via a Venturi nozzle, through to the use of electric dosing pumps. However, all these methods incur disadvantages for the operator, which are briefly explained in the remainder of this article.

Manual dosing always entails the risk of over- or under-dosing. Too much water in the solution means the tools are not adequately lubricated and cooled. The solution evaporates too quickly and the tools wear out faster, potentially leading to unclean results for the finished part. If, on the contrary, too much concentrate is used, the expensive concentrate is also used up more quickly. More time is also required to prepare the cooling lubricant solution and the staff risk coming into contact with the concentrate.

Use of a Venturi nozzle is another option for dosing without the use of electricity. The Venturi nozzle causes a reduction in pressure in the stream of water flowing through it, which draws the concentrate out of its container and into the water stream. However, the limitations of this method are soon met if longer pressure pipes or viscous dosing media are used. The dosing rate is dependent on temperature, water pressure, water flow rate and counter pressure all at the same time.

The calibration and setting of the necessary quantity of cooling lubricant is difficult and needs to be done again if there are fluctuations in the flow rate.

A LOOK AHEAD

In comparison to this, an electrically-powered piston or membrane dosing pump feeds the required dosing quantity into the process flow according to the set stroke or pulse rate. The dosing is designed to be intermittent based on pulsation. This means that a homogeneous and usable solution is only produced in a downstream mixer or by mixing in a container. This incurs additional equipment and installation costs, and means that the quality of the concentrate solution applied is inconsistent. Use of an electric drive also entails the risk the pump failing in the event of a power cut.

Modern, electronically-controlled dosing pumps are often overloaded with electronic application options that are often not required for cooling lubricant dosing, yet still have to be paid for with the equipment. In next month’s conclusion, we’ll take a closer look at the solution to this, the LDT Dosatron proportional dosing system, which can be integrated into different, customer-specific systems.

For more information:

With a wide product range of metering pumps from leading international manufacturers, such as Dosatron, Iwaki, Doseuro, and Etatron, LDT Dosiertechnik GmbH offers standard and customized solutions for a variety of metering applications, all supported by a wide range of accessories. For more information, visit www.ldt.info.

____________________________________________

MODERN PUMPING TODAY, April 2017

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!![]()