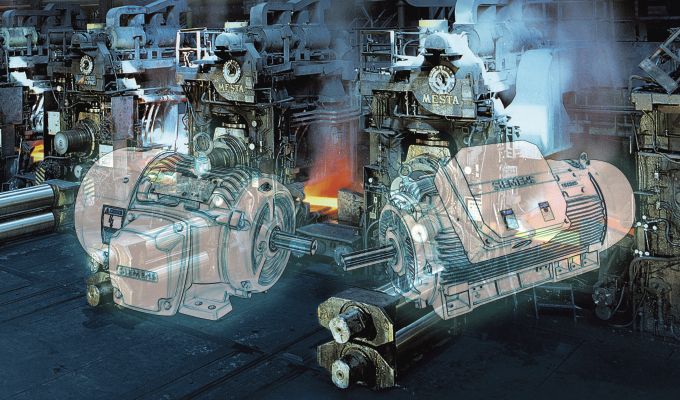

When it comes to power, whether it’s the oil and gas market, petrochemicals, grain or rock product, food and beverage, or near countless other harsh environments, efficiency is everything. The Simotics SD200 440 low-voltage, severe-duty AC motors, which now provide a range from 75 to 800 horsepower output, are ready for the challenge—meeting or exceeding NEMA Premium® MG1 Table 12-12 efficiencies.

MEETING TOUGH CONDITIONS

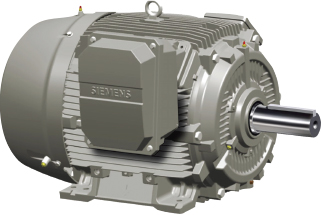

Providing high productivity and energy-efficient operation in all torque ranges, these cast-iron NEMA motors are built to power pumps, fans, compressors, hoists, winders, and similar equipment in harsh environments. The motors feature 444-5013 cast-iron frames for operation in 460V and 575V ranges. A wide selection of options is offered, including IP56 ingress protection, encoders, brakes, and blowers plus others to suit the applications presented.

On these motors, the frame, end-shields, fan guard, and easy-access, diagonally split, oversized terminal box are all cast-iron. Complementing this construction are zinc-plated hardware, epoxy paint, and stainless-steel nameplates for long life and easy identification in the field. A unique offset rotor bar provides improved efficiency, while larger bars and end rings reduce resistance. Each die-cast aluminum rotor assembly is dynamically balanced for extended bearing life and includes a high-strength C1045 carbon steel shaft for maximum performance. Premium C5-grade steel laminations and copper magnet wire are standard.

FACING THE HEAT

For insulation, the Class-H non-hygroscopic system with NEMA Class B temperature rise provides an extra margin of thermal life. The insulation system meets or exceeds NEMA MG1 2014 Part 31, making these motors suitable for variable speed drives in constant torque (4:1) and variable torque (20:1). All windings are tested for Corona Inception Voltage (CIV).

The Siemens product manager for low-voltage NEMA motors, Oscar Palafox, explains, “One of the features of the SD200 is its flexibility in the field, as the motor can be switched from F1 to F2 and F3 orientation with ease. Plus, the safety features on this new line are unmatched by competition. Full H-Class conformity provides winding protection, while the swivel hooks are a significant improvement over eyehooks for handling of these heavy units. In addition, the unique Siemens composite insulation on the SD200 is a cost-saver over the ceramic bearing alternative with ten times the resistance of other solutions in the market.”

GOING THE DISTANCE

Even with tough conditions in mind, Siemens backs the SD200 with a three-year warranty.

“Finally, the NEMA Premium efficiency is a guarantee of long performance life with very tight deviation of losses. Shaft current remains more consistent for better uptime,” Palafox adds. He further notes this line affords users Division II, Class 1 (gas) and Class 2 (dust) protection.

FOR MORE INFORMATION

Siemens USA has been a national asset moving America forward for more than 160 years, investing three billion dollars in the U.S. market, strengthening its technology portfolio and manufacturing footprint. The company’s technology supports the critical infrastructure and vital industries forming the backbone of America’s economy. With customers in all fifty states and Puerto Rico, Siemens USA employees and suppliers are creating more agile and productive factories, more intelligent and resilient buildings and power systems, and more reliable and sustainable transportation. For more information, visit www.usa.siemens.com/simotics-sd200.

MODERN PUMPING TODAY, September 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!