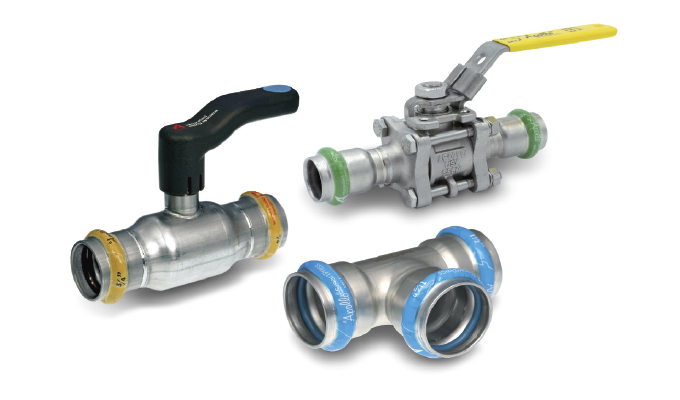

Aalberts integrated piping systems (IPS), a global leader in advanced integrated piping systems for the distribution and control of liquids and gasses, is proud to highlight its innovative “Apollo” SmartPress® product line, designed to set new standards in press connection systems for stainless steel pipes. Engineered for maximum reliability and efficiency, “Apollo” SmartPress offers a range of advanced features that cater to the most demanding industrial and commercial applications.

In the power generation industry, the “Apollo” SmartPress line ensures high durability and the ability to withstand pressurized systems which is critical in power plants. Its high operating pressure, temperature range, wide range of fittings and valves, and pre-marked insertion depths allow for quick and easy installation, therefore reducing downtime and labor costs. The “Apollo” SmartPress is stronger than traditional systems, ensuring no material removal or pipe wall thickness reduction. It is also a flameless system, eliminating the need for open-flame safety precautions and requirements. The “Apollo” SmartPress is ideal for cooling systems, water distribution, or steam pipelines, and complies with applicable industry standards including ASME B31.1, FM Approvals Class: 1920 and UL 213.

INNOVATION YOU NEED

At the core of the “Apollo” SmartPress line is its patented smart sealing element technology, which transforms how fittings interact with pipes. This innovative solution provides multiple functions in one. The unique geometry of the sealing element creates a secure pipe grip, preventing the fitting from falling off during installation and ensuring precise alignment. Installers can immediately detect when the fitting is properly in place, as the sealing element offers tactile feedback for optimal alignment and consistent performance. Additionally, the system features built-in Leak Before Press technology, which allows for the mechanical detection of unpressed connections during pressure testing, providing both visual and tactile confirmation of a proper seal.

The “Apollo” SmartPress system is compatible with AISI type 304/304L and 316/316L stainless steel, ensuring versatility across industries such as chemical processing, food and beverage production, pharmaceuticals, power generation, and data centers. Its wide temperature range, from -31 to 446 degrees Fahrenheit, and support for pressures up to 500 psi make the “Apollo” SmartPress suitable for both high- and low-pressure applications, ensuring system integrity even in extreme environments.

SOLUTIONS FOR TODAY’S INDUSTRIES

The “Apollo” SmartPress line addresses the growing need for reliable, efficient, and safe press connection systems in today’s industrial landscape. By incorporating groundbreaking features like smart sealing technology and Leak Before Press® technology, Aalberts IPS delivers a product that meets the stringent demands of industries where standards of safety, precision, and performance are paramount.

The “Apollo” SmartPress system is designed for simplified installation, offering pre-marked insertion depths, color-coded materials and sizes, and Visu-Control® foil technology, which ensures proper installation and reduces the risk of errors. These features allow for quick and accurate installation, minimizing downtime and improving operational efficiency. The “Apollo” SmartPress line is incredibly versatile. With a wide range of fittings and valves available from 1/2 to 2 inches, the “Apollo” SmartPress can adapt to a variety of commercial and industrial piping systems.

The product line is manufactured in a silicone-free environment, reducing the risk of contamination, which is particularly important for sensitive applications such as pharmaceutical processing and cleanrooms in high-tech industries like battery production.

The “Apollo” SmartPress system adheres to critical industry standards, including ASME B31.3 for process piping, NSF/ANSI/CAN 61 and 372 for potable water safety, and FM Approvals Class 1920 and UL 213 for fire protection in high-risk environments such as power plants and data centers.

CASE STUDY: APOLLO SMARTPRESS SOLUTIONS FOR FOOD MANUFACTURER

At Aalberts integrated piping systems, our commitment to advancing industrial solutions is exemplified by our recent project with a prominent grocery provider specializing in breaded chicken breasts. This case study highlights the effectiveness of our “Apollo” SmartPress valves and fittings in supporting food safety and efficiency.

- Location: Langley, British Columbia, Canada

- Market: food and beverage

Challenge

The client required an upgrade to their production facility to increase the output of breaded chicken while adhering to strict food safety standards. A key element of this expansion was the installation of a new freezer system to maintain critical temperature control and sanitary conditions, essential for food safety and operational efficiency.

Solution

For this project, approximately thirty to forty “Apollo” SmartPress valves and hundreds of fittings were utilized to manage various systems, including air and water supply, hot and cold water applications, and hot water recirculation. These systems ensure the efficient operation of heating processes and included high-pressure washdown (CIW) and Clean in Place (CIP) solutions, crucial for maintaining cleanliness without dismantling equipment.

Key features of “Apollo” SmartPress:

- Color-coded Visu-Control foil: Simplifies material and dimension identification, enhancing installation safety and speed.

- Leak Before Press® technology: Detects leaks before pressurization, ensuring optimal safety and performance.

- quick installation: Pre-marked insertion depth and easy-to-use design reduce installation time and labor costs.

Outcome and Benefits

The integration of “Apollo” SmartPress valves and fittings significantly streamlined the installation process, improving the efficiency and safety of the client’s production facility. These systems maintained critical temperatures and sanitary conditions, supporting continuous, reliable production in a demanding food and beverage environment.

Key metrics

- Total products used: 30-40 valves, hundreds of fittings

- Impact on operations: Streamlined installation, reduced maintenance, improved food safety compliance

CONCLUSION

This project underscores Aalberts integrated piping systems’ ability to support the food and beverage industry in meeting safety, efficiency, and scalability challenges. Our “Apollo” SmartPress solutions provide the reliability and performance necessary to meet the rigorous demands of food processing environments, ensuring companies can deliver high-quality products safely and efficiently.

Aalberts integrated piping systems (IPS) is a global leader in creating mission-critical valve and connection technology through its “Apollo” brand with a legacy spanning 96 years. The product profile includes ball valves, butterfly valves, safety relief valves, control valves, mixing valves, and backflow preventers, serving many industries such as residential, commercial, industrial, and utility markets. The company’s commitment to quality is evident in its proactive design and manufacturing processes, with a significant portion of production proudly conducted in the United States. For more information, visit www.aalberts-ips.us.