In many applications, metering ingredients in the pharmaceutical or food industry for example, pumps are required that not only can be precisely controlled in terms of flow rate and dosing time, but also convey the ingredients particularly gently. To enable the proven pump units of the ecodos series from Lewa GmbH to fulfill this demanding task with even more flexibility and energy efficiency in the future, the manufacturer is expanding the portfolio to include a new form of wide-range speed control. Alongside asynchronous motors and servomotors, permanent magnet synchronous motors, or PMSMs for short, are also used now. They are characterized by high energy efficiency and a control range greater than 1:200. This significantly expands the range of applications. With PMSMs, it is no longer necessary to use several pumps for different flow rates or oversize asynchronous motors for low speeds. Since PMSMs can be designed without a fan, they remain compact and easy to clean. The latter feature predestines them for hygienic applications. High efficiency rating over the complete control range in accordance with energy efficiency class IE5+ also reduces energy costs, thus ensuring a lower total cost of ownership (TCO).

EXPANDING THE HORIZON FOR METERING PUMP PERFORMANCE

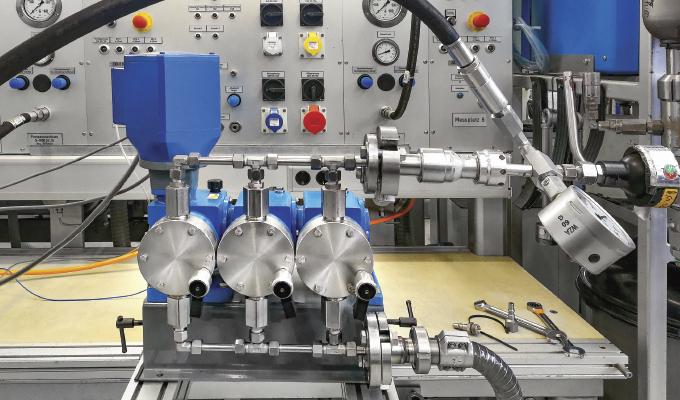

The diaphragm metering pumps in the Lewa ecodos series are particularly well suited for applications in the food or pharmaceutical industries. All materials in contact with the fluids used in the pump units meet the FDA and USP Class VI requirements, and the EU directives for the food industry. In the hygienic version, for example, the pump head is made of PP or electropolished stainless steel with a surface roughness < 0.5 µm. This facilitates cleaning of the surfaces in contact with the product.

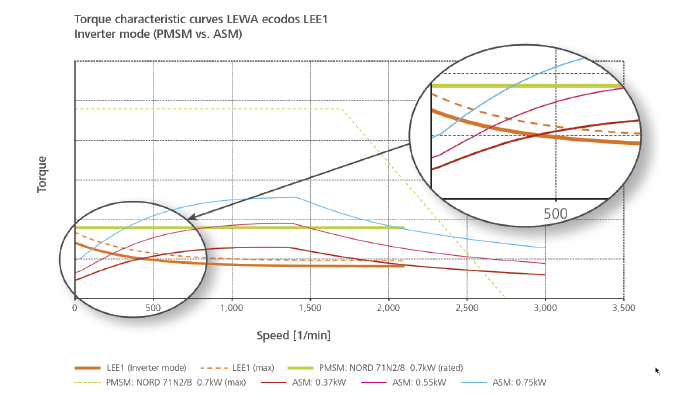

The motor technologies used to date have had to make sacrifices: for classic asynchronous motors whose rotor is a squirrel-cage rotor, the control range remains limited to 1:10 (1:50 is possible in individual cases). With encoder feedback, significant expansion is possible. In addition, the drive is relatively inefficient outside the rated speed range—especially at low speeds. This requires the drive to be oversized, which increases operating costs. Servomotors are optimized for highly dynamic requirements and also cover the complete control range (1-210 pump strokes); however, they are more expensive to purchase and in addition, require a servo inverter for control.

WIDE-RANGE SPEED EXTENDS THE RANGE OF APPLICATIONS

Lewa has now expanded its own portfolio with a drive technology that does not have these weaknesses. Unlike the asynchronous motor, the rotor of this drive consists of permanent magnets and rotates synchronously, i.e., without load-dependent slip. Among other things, it features an extreme control range, which often makes the use of multiple pumps for different flow rates unnecessary. Particularly in the case of multiple pumps, an additional manual stroke adjustment or electric stroke adjustment can be dispensed with and the required flow rate can be realized by speed control only. The PMSM also has a constant torque. The complete torque can be applied from engine speed 0 rpm (standstill) up to the rated speed of the motor. This ensures particularly smooth and gentle system start-up, since each process can be started with a pump capacity of 1 percent instead of the usual 10 percent.

It also features a high short-term overload capacity, which enables a drive design without oversizing for the starting torque. As a result, smaller, more cost-efficient sizes can be realized than with classic drives. Like the asynchronous motor, the PMSM can be controlled via a standard frequency converter, so users can rely on common parts. With the servomotor on the contrary, it would be necessary to purchase expensive servo controllers. The compact drive can be easily cleaned due to its fanless design and offers high IP protection. If required an additional conversion process—called nsd tupH—can be applied to the aluminum body for FDA requirements. This makes the surface extremely resistant and even easier to clean—ideal for applications with stringent hygienic requirements, such as aroma metering in the food industry or additive dosing in the pharmaceutical industry.

IE5+ PMSM ENABLES COST REDUCTION AND DECENTRALIZED SOLUTIONS

The sole limitation of the currently used PMSM is that it is only available for safe areas. Summing up, thanks to wide-range speed control with IE5+ PMSM, we can meet the increasing customer demands for a wider adjustment range and lower energy consumption, as well as overall costs. The topic of energy efficiency in particular is becoming increasingly important for our customers. A decentralized solution in which the frequency converter is installed directly on the PMSM, can now be implemented with Getriebebau NORD GmbH & Co. KG, Lewa’s motor partner for PMSM, too.

FOR MORE INFORMATION

Maurice Wirkner is an application manager at Lewa GmbH. Lewa is the world’s leading manufacturer of metering pumps and process diaphragm pumps as well as complete metering packages for process engineering. The Leonberg, Germany-based company developed into an international group within a few decades and saw further improvement in its position on the world market as part of integration into Japanese Nikkiso Co. Ltd. in 2009. As a research and production-oriented company, Lewa develops technologies and provides solutions for the vast array of applications among its customers. Its products are used mainly in the oil and gas industry, in gas odorization and in refineries and petrochemicals, as well as in the production of plastics, detergents and cleaners. Additional application areas include the chemical industry, the cosmetics industry, pharmaceuticals and biotechnology, food and beverage industry and energy utilities. For more information, visit www.lewa.com.

MODERN PUMPING TODAY, March 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!