In last month’s introduction to this article, we discussed how the evolution of ISO standards has gradually refined life calculation methods to help close the gap between the calculated life of a bearing and the anticipated service life in an application. In this month’s conclusion, we’ll take an up-close look at SKF’s EnCompass Program, including the calculation software SimPro Quick and SimPro Expert, which equip engineers with both the knowledge and the means to promote ideal bearing selection.

OPTIMIZED DESIGNS

Supporting the axiom that better knowledge yields better products and technologies, the EnCompass Program with its bearing rating life model has already been leveraged to optimize four existing SKF bearing product lines. They are SKF Explorer sealed spherical roller bearings, SKF Energy Efficient deep groove ball bearings, SKF Energy Efficient Y-bearings and units, and SKF Explorer steel/steel plain bearings. More innovations and upgrades for additional bearing types are on the horizon.

Among the improvements: new bearing designs and engineering, weight reductions, specialized surface finishes and heat treatment, ready-to-mount unit assemblies, and optimized lubrication and sealing systems, among others.

For example, upgraded SKF Explorer spherical roller bearings in the smaller size range include a new seal design that results in up to 50 percent less seal friction, allowing operating temperatures to be reduced by up to 68 degrees Fahrenheit (20 degrees Celsius) and enabling limiting speeds to be doubled. All SKF Explorer spherical roller bearings, since 2011, also incorporate improvements such as special surface finishes and heat treatment, which can deliver a service life twice that of the previous industry-leading SKF Explorer bearings, especially under contaminated or poor lubrication conditions.

As another example, SKF Energy Efficient deep groove ball bearings now cover a larger size range, allowing designers to reduce energy usage in a broader assortment of machines. Any reductions in energy use can prove especially advantageous in the process pump industry, based on energy-related numbers. Studies have shown that 5 percent of all industrial energy is estimated to be consumed by pumps; in certain industrial plant operations pumps can account for up to 25 percent of energy usage; 20 percent of the world’s electrical energy demand can be attributed to pumping systems; and fully 45 percent of the total cost of pump ownership can be linked to energy consumption. Any energy savings will ripple positively across pump operations.

SOFTWARE ADVANCES

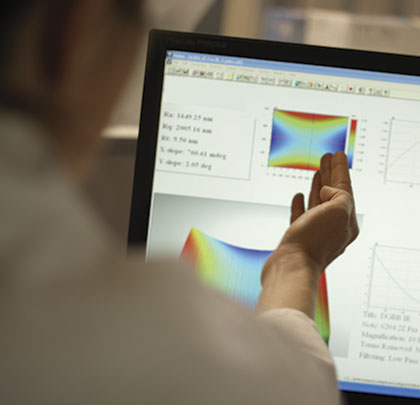

Dedicated to improving bearing performance in the field, the SKF EnCompass program has led to a new family of advanced software tools, too. Two proprietary SKF calculation software programs—SimPro Quick and SimPro Expert—have been introduced to equip engineers with both the knowledge and the means to promote ideal bearing selection and fine-tune the designs of pumps or other machinery to achieve optimal field performance, based on application requirements and conditions.

The SKF SimPro Quick is a single-shaft bearing simulation software program, which guides users through a series of steps and simplifies calculations required to correctly select the most appropriate bearing for the job. The SimPro Expert program allows in-depth analysis of more complicated, multi-shaft designs and is ideal for engineers involved in the design of very complex bearing systems. Both software programs enable engineers to consider shaft, housing, bearings, external forces, and gear loads when it is time to specify for an application.

Prevailing trends in the pump industry swirl with requirements to reduce energy consumption, increase system service reliability, reinforce robustness, minimize maintenance, and comply with stringent safety and environmental regulations. Advantages flowing from the new bearing rating life model, associated innovations in a range of bearing types, and software programs to assist in bearing selection can combine to help remove many of the pressures typically confronting pump operations every day. ◆

Brian P. Dahmer is an application engineering manager at SKF USA Inc., the world’s leading bearing manufacturer. He can be reached at brian.p.dahmer@skf.com. For more information, visit www.skfusa.com.

____________________________________________

MODERN PUMPING TODAY, September 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()