Missed part 1? Read it here.

In last month’s introduction, we discussed how double-containment piping, although not specifically required by today’s stricter safety mandates and regulations, are a popular option for those looking to address growing concerns about environmental protection. As a reminder, double containment involves a piping system (“primary”) inside a piping system (“secondary”), creating a fail-safe method for the conveyance of fluids.

System designers can choose thermoplastics such as PVC, CPVC, PVDF, and polypropylene. Metal pipe options include carbon steel, stainless steel, and copper. Some manufacturers even offer customized combinations of metallic and thermoplastic systems to satisfy the most demanding industrial applications.

MATERIAL AND APPLICATION FLEXIBILITY

This material flexibility allows system designers and installers to adapt to a wide range of applications that mandate containment piping for the transport of hazardous, corrosive, or aggressive chemical fluids. Among the more common of these are:

- Chemical processing

- Water and wastewater treatment

- Pharmaceutical manufacturing

- Battery manufacturing and recycling

- Semiconductor manufacturing

- Generator backup systems

A recent successful example involved the Clarion Altela Environmental Services (CAES) facility in Clarion, Pennsylvania. Here, double containment was crucial for transporting untreated frac water. Due to the chemicals and saline present in the water, a double containment piping system was required to transport it from incoming tank trucks to holding ponds, and from there to the treatment-processing equipment at CAES.

“Frac water recycling is a fairly new process, and the project didn’t start out requiring a double containment system for the piping,” explains Walter Smith, former mechanical engineer with Mid Penn Engineering and the system designer.

“During approvals, the [state] Department of Environmental Protection decided to require double containment for any area where buried pipes would be transporting untreated frac water. This was to prevent any possibility of leakage into the surrounding soil. Once the piping went inside the facility, we were able to transition to a single wall system.”

Engineered double-containment systems are known for their relative ease of installation. Many manufacturers offer hands-on training to make installation even faster and more efficient.

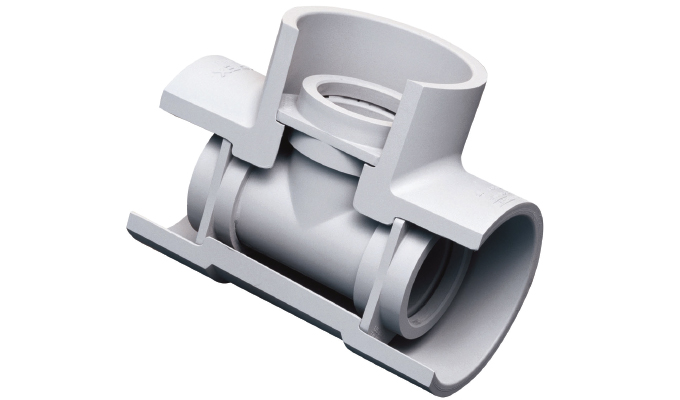

Because double containment systems feature prefabricated, modular components that simplify the setup process and minimize the number of joints, labor and overall project costs are typically reduced. The risk of leaks and maintenance issues is also lessened, ensuring long-term reliability.

That was the case at the CAES facility, where fewer joints lowered installation costs while enhancing end-user safety. The double containment system has operated reliably without leaks, demonstrating its effectiveness in handling sensitive fluids under strict regulations.

LET’S ALSO KEEP PEOPLE SAFE

As noted, double containment piping systems are for more than mandated or code-compliant situations involving the safe conveyance of dangerous substances underground. It can be used in systems conveying any type of fluid above sensitive areas. Some important examples of applications where double containment can be used to protect people and vital information are:

- Healthcare facilities

- Data centers

- Libraries and museums

Hospitals are an especially critical application. A leak could create a substantial risk to health and even life in these facilities. That is why many facilities are choosing to double-contained piping systems over all the important areas.

Would you really need to contain a sanitary line in a hospital? What about drip trays: Wouldn’t they be enough?

Even a drain, waste, and vent leak would be a massive problem for a facility on perpetual alert against pathogens, bacteria, and viruses. Shouldn’t that DWV pipe be locked up as tightly as possible for maximum protection?

What harm can a potable water leak create in a hospital? In applications where the potable water piping runs overhead, such as through the ceiling of an operating room, a leak could interrupt a surgery. Wouldn’t any sort of leak in the midst of a surgical procedure create serious, even life-threatening dangers?

THE RIGHT WAY FORWARD

Double containment is an excellent way to protect the environment, minimize liability, and meet EPA mandates and other legal requirements. But double containment is also the right thing to do to protect people, sensitive information, and valuable property.

It may be necessary to have double containment of underground pipelines full of corrosive chemicals. But what about those same pipelines running overhead inside a factory? Don’t we want to avoid leaks in that piping and the harm they could cause workers?

Or what about piping running through critical areas where a leak could down production, damage artifacts, cause a loss of critical information, or—even worse—cause harm or death? So, let’s not just double-contain per mandates and codes. Let’s also double-contain because it’s the right thing to do.

Steven Dolejsi received a B.S. in mechanical engineering from Ryerson University and is the applications engineering manager at IPEX, where he has worked for over nineteen years. He can be reached at steven.dolejsi@ipexamerica.com. As the North American business of global leader Aliaxis, a leading manufacturer of thermoplastic piping systems, IPEX has more than 60 years of experience and is a leader recognized for designing and manufacturing innovative solutions to the world’s water challenges and a transition to clean energy. Our state-of-the-art manufacturing facilities, new R&D center, and distribution centers across Canada and the United States employ over 4,000+ people committed to a sustainable future and our approach to environmentally responsible manufacturing. For more information, visit www.ipexna.com.