Boiler feed water is thermally and chemically degassed to achieve oxygen-free water, a state which must be maintained throughout the steam cycle. The Electro-Chemical Devices (ECD) Model DO90 Trace Dissolved Oxygen Sensor offers reliable and effective monitoring of boiler feed water. Oxygen should only be present in trace quantities in boiler feed water, as excessive concentrations of oxygen can result in corrosion damage to the components of the steam cycle.

MODEL DO90 TRACE DISSOLVED OXYGEN SENSOR

Engineers responsible for maintaining boiler operations will find the new Model DO90 Trace DO2 Sensor from ECD is designed for the continuous and highly accurate measurement of trace levels of dissolved oxygen, helping to maintain oxygen-free boiler feed water and reducing corrosion.

The Model DO90 Trace DO2 Sensor is a lead-silver galvanic sensor with a durable PFA Teflon® membrane. As a digital sensor, all of the signal conditioning, calibration, and diagnostic functions are performed inside the sensor. Its signal is noise-free and it features zero calibration and air calibration.

The Model DO90 flow cell has been specially designed for use with the Model DO90 Sensor. The orientations of the inlet and outlet sample lines automatically purge air from the flow cell. The measurement chamber is optimized for fast response and all wetted parts are 316L stainless steel. The DO90 sensor is also compatible with ECD’s T80 Analyzer, which also works with all Model S80 Sensors.

FEATURE-RICH PERFORMANCE

The DO90 Sensor offers a large measurement range, from 0.001 to 20.00 mg/L. Long-term stability means that drift is less than 1 percent per month. Needing virtually no maintenance, the DO90 sensor has an easily replaceable electrode cartridge, eliminating the need for messy electrolyte/membrane replacement kits.

The Model DO90 Trace DO2 Sensor is available as separate components, sensor, fittings, flow cell, Model T80 Transmitter, or as a complete panel mounted system. The panel mount system is a complete plumb-and-play device. The system is also available as a complete kit, less the panel, for mounting to an existing water panel. Installation of the flow cell is also easy, using either the clamp style holders for wall mount or the two 10 x 32 threaded ports on the backside of the flow cell for panel mounting.

ECD SIX-POINT ADVANTAGE

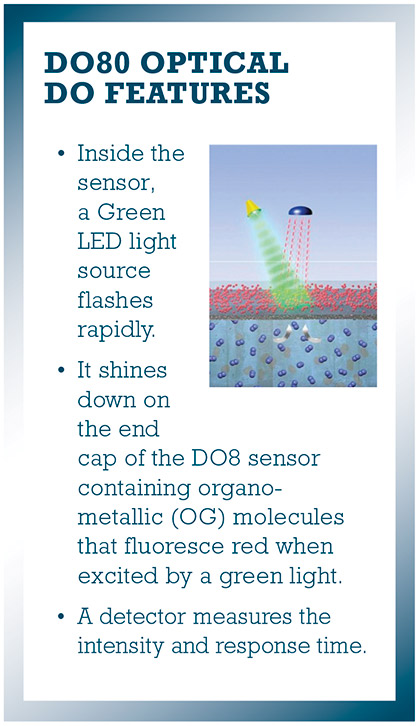

Other ECD Disolved Oxygen products include Optical Sensors, the DO80.

- Optical Dissolved Oxygen Analyzer System: DO sensor uses Fluorescence Quenching Method for better performance and less maintenance in municipal wastewater and industrial wastewater applications.

- Intelligent Sensor with Stored Calibration Data: advanced 2nd generation software algorithms and digital communication.

- ULTRA Long Life Membrane Cap: provides years of service, there is no required/recommended annual membrane replacement.

- Membrane Cap is Easily Replaceable: if physically damaged, there is no need to return the sensor for factory repair or replacement, saving time and money.

- Universal Design with Waterproof Fixed or Detachable Cable: Available with hand rail mounted immersion assemblies, flow through cells, and automatic spray cleaning systems.

- Interfaces with T80 Transmitter or C22 Controller: 4 to 20 mA with MODBUS RTU or HART Communication, Relays, Timers, and more. ◆

About The Author

Joe Bradley is director of sales and service at Electro-Chemical Devices (ECD) is a manufacturer of liquid analytical process instrumentation. Founded in 1977, ECD has been in business for more than thirty years and has built its industry leading reputation by its commitment to customers through this basic approach: Provide quality products, develop technical innovations, and provide responsive, knowledgeable service. For more information, email sales@ecdi.com or visit www.ecdi.com.United States and Canada.

____________________________________________

MODERN PUMPING TODAY, December 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()