Submersible pump stations around the world share a common enemy, the not so “flushable” wipe. In a tradition wet well system, these wipes are separated from the pumped liquid, solidify and form clogs that result in costly maintenance service calls. But one system solves this problem entirely: OverWatch® Direct In-Line Pump System eliminates the root cause, the wet well.

PROJECT OVERVIEW

In Austin, Texas, a twenty-three-story, 320-unit high-rise residence building with a grocery store and restaurant was plagued by frequent pump clogs—six faults in two months! The culprit, as is often the case in contemporary waste streams, so-called flushable wipes. Despite multiple notifications to the building occupants, the building management team had no control over what the occupants flushed. Clogs persisted and non-budgeted pump service charges were piling up. They needed a solution that would allow the team to refocus on their main priority—providing premium living conditions for the residents.

The team selected the OverWatch Direct In-Line Pump System to solve the repeated clogging and maintenance problems.

PROBLEM UP-CLOSE

Although many people believer that cleaning wipes and other modern conveniences are flushable, they do not belong in municipal waste streams. Below are some of the problems that result from these items landing where they don’t belong:

- Constant clogging from “flushable” wipes

- Excessive maintenance costs for emergency service visits to remove clogs and fat, oil, and grease (FOG)

- Offensive odors

SOLUTION

The Pumps of Houston service team quickly removed the antiquated submersible pumps, piping, rails, and control panel. With the equipment removed, the 60-inch diameter fiberglass basin prepped for the new dry-pit system. The OverWatch arrived factory pre-tested, pre-wired, assembled, and ready to be installed. Within two and a half hours, the wet well was transformed into a dry pit and the OverWatch installation had begun 10 feet below ground.

In a safe, clean, and dry environment, the team was able to connect the suction directly to the invert and construct the discharge piping. A sump pump was used in conjunction with the system to handle any water ingress from the hatch. The valve vault was no longer needed and could be removed during future construction. In just one day, the source of much pain and expense had been converted from a wet well into a dry, clean, and reliable pump station.

WHY OVERWATCH?

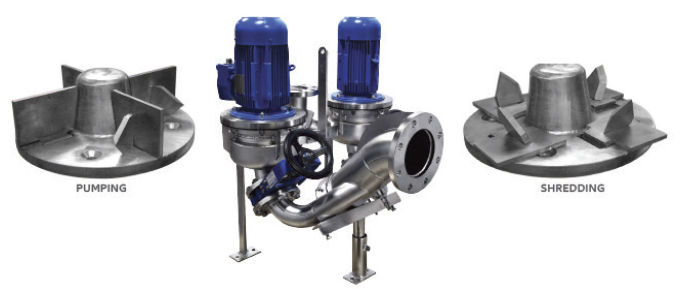

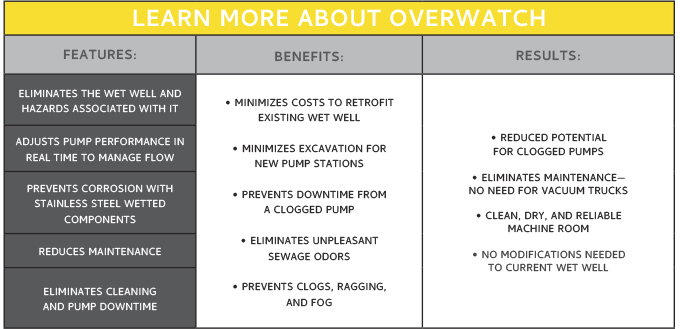

The management team needed a robust and sustainable system that also detects and annihilates potential clogs without human intervention. By removing the wet well and installing an OverWatch system, influent is lifted directly from the gravity invert, wipes, and fat, oil, and grease (FOG) do not have the opportunity to separate from the pumped liquid, keeping the fibrous material in solution and ejecting it as it arrives. Since the influent is contained, it never become atmospheric, eliminating odors, a huge issue in the Texas heat.

This game-changing technology not only eliminates the wet well, but also eliminates clogs, odors, gases, and maintenance. The building management team is saving time and money with this installation.

FOR MORE INFORMATION

Industrial Flow Solutions (IFS) headquartered in New Haven, Connecticut, specializes in the design, manufacturing, sales, and service of wastewater pumps and controls including OverWatch® Direct In-Line Pump Systems, BJM Pumps®, Stancor®, Oil Minder®, and DERAGGER™ products ideal for the municipal, industrial, commercial, and residential applications. With over 200 years’ technical and application experience, IFS supports partners through the design, build, test, install, and post-install processes. In the New Haven location, a state-of-the-art, in-house testing facility that is built to Hydraulic Institute Standards enables comprehensive testing with rapid results. With a focus on turning customers’ flow problems into flow solutions, IFS products lower costs, increase efficiencies, and minimize the environmental impact. IFS is committed to offering industry leading response times with a high human touch from initial inquiry to post-installation support. For more information, visit www.flowsolutions.com.

MODERN PUMPING TODAY, November 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!