The plumbing profession is all about trust—using tried and true methods that have stood the test of time to ensure that pipe connections will not leak. Plumbers are understandably skeptical about adopting major changes until new techniques earn their trust.

For a century, water and HVAC systems were almost entirely constructed of copper pipes and soldered/brazed pipe joints. This all began to change in the new millennium. PEX, originally used in radiant floor heating, started to become prevalent in plumbing applications, along with CPVC, in the late 1990s.

With these new materials came an alternative connection method that was faster, easier, and safer than soldiering. Press fittings were invented in Germany in 1989, but crimping with press fittings did not gain wide acceptance on this side of the Atlantic until years later—in the early 2000s—after the method had proved its reliability throughout Europe for more than a decade.

NEXT-GEN PUSH FITTINGS ARE MORE DURABLE THAN PRESS FITTINGS

Now, a third connection method—next-generation push-to-connect fittings—has become increasingly prevalent in the plumbing and HVAC trades along with soldering and crimping.

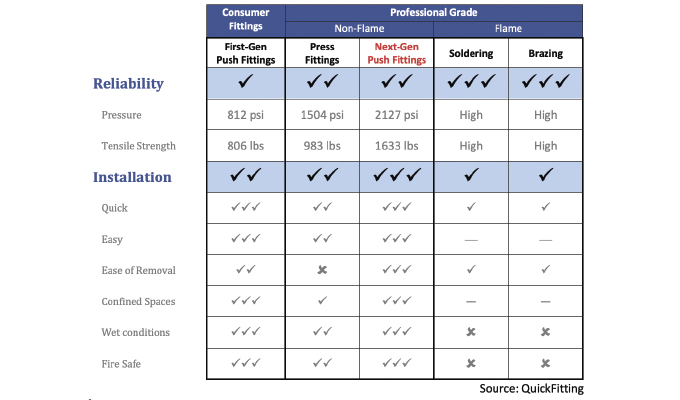

These next-gen push fittings are engineered with new technology that makes them stronger and more reliable than the first-generation push fittings popular in the consumer DIY market, and even stronger and more reliable than press fittings. All these different types of fittings use O-rings for the seal, but the key difference is the strength and durability of the grip that holds the O-ring in place and preserves its integrity.

At QuickFitting, our engineers have earned over fifty U.S. patents designing the next generation of press fittings with innovations that include dual seal designs and advanced machine edge technology for superior performance and sealing characteristics.

These next-gen push fittings were subjected to extensive hydrostatic pressure and tensile strength tests performed by Roger Wakefield, “The Expert Plumber” with nearly a half million subscribers on YouTube. The next-gen press fittings held up to 2,127 psi, compared to 1,504 for press fittings and only 812 psi for first-gen push fittings. The difference in tensile strength was even more impressive: it took 1,633 pounds of force to pull apart the connection and cause a leak in with the next-gen push fitting, approximately double the force required to cause a failure with the alternatives.

Indeed, the new technology is so effective, that QuickFitting couplings and valves are backed by a seventy-five-year warranty that covers the full cost of repairs and damage—exceeding the expected lifespan of copper pipe (fifty to seventy years) and of PEX (thirty to fifty years).

WHEN ARE PUSH FITTINGS THE BEST OPTION?

The low cost per part of fittings usually makes soldering and crimping the most economical solution for new construction and projects requiring many pipe joints. But there are many applications where push connect fittings and valves are the most efficient and cost-effective method.

With push-to-connect fitting, installation is easy and requires fewer steps than other connection methods. Without any soldering, gluing, or crimping required, safety is greater, risks are lower, and installation is up to 70 percent faster.

When you want to get in and out of a job quickly, to get on with your business and to let your commercial customer get back to business as soon as possible.

- When transitioning between copper, PEX, PE-RT, or CPVC pipes and tubing.

- When conditions are too wet for soldering, or too cramped or hard to reach for crimping equipment.

- When you are being assisted by a helper or trainee with limited experience soldering and crimping.

- When you have a simple plumbing job that can be done quickly, like moving an icemaker, replacing a water heater, or repairing a toilet water supply valve.

- When you anticipate the need to remove and reposition piping in the future, for temp0oraty installations, multi-staged renovation projections, etc.

- When you want to get a day’s worth of jobs done before noon.

EXTREMELY EASY PROCESS

Installation is extremely easy, and requires only four steps:

- Cut the copper, PEX, PE-RT, or CPVC tubing using a sharp tubing cutter.

- Clean the connected surface making sure it is clean, burr free and free of foreign materials

- Mark the insertion depth.

- Push on the fitting or valve to the insertion depth mark.

A feature of next-gen push fittings is ease of removal to allow fittings to be repositioned or removed. The fittings themselves have been tested to continue to maintain gripping performance and sealing characteristics after 1,200 cycles of installation and removal. The QuickFitting patented SlipClip release tool allows for simple and quick disconnection with minimal effort by snapping the clip onto the fitting from the side with the press of a finger. This design is an important improvement over first generation press fittings which require the application of be of a great deal of force to the end of the fitting.

THE EASIEST WAY TO REPAIR A PIPE OR ADD A BRANCH

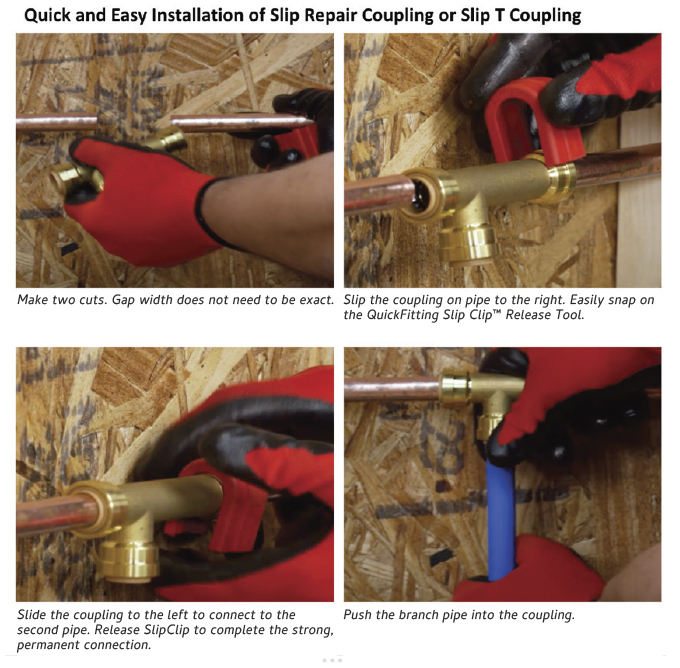

Let’s look at a typical installation or repair using a Slip Repair Coupling to highlight some of the advantages of next-gen push fittings.

For most repairs, only a single QuickFitting Slip Repair Coupling is needed, compared to the two sweat copper fittings that are traditionally used. And there is no need to find and prepare a length of a specific pipe type to fit in between. Slip repair couplings are also more forgiving and therefore it is not necessary for the cut distance exactly right.

The installation of a Slip Repair Coupling is facilitated by the SlipClip, which easily releases the connection on one pipe to allow the coupling to slide onto the other pipe. Once the second pipe is fully inserted into the coupling, simply remove the SlipClip, to complete the strong, permanent connection of the two pipes.

The process is the same for a Slip Branch T, with the addition of the final step of pushing the branch pipe into the coupling.

There is no faster way to repair a pipe in an emergency. And the process can be performed without any tools, flames, or chemicals, even in the wet conditions that are typical of most emergencies.

OPTIMAL SOLUTION FOR MANY PLUMBING APPLICATIONS

Now that next-gen press fittings have proven to be at least as reliable as press fittings, plumbers and HVAC contractors are increasingly turning to them as a cost-effective and time-saving option. Next-gen press-fittings are a fast, easy, safe, and professional-looking alternative that have earned their place in the tradesman’s van, next to the sweat fittings and press fittings.

FOR MORE INFORMATION

Matthew Boucher is CEO of QuickFitting. As one of the industry’s leading suppliers of repairable quick connection fittings for industrial, municipal, OEM, and plumbing, electrical, and HVAC markets, QuickFitting designs and delivers proven, reliable, and innovative pipe, wire, and conduit fittings and valves for demanding conditions. For more information, visit www.quickfitting.com.

MODERN PUMPING TODAY, February 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!