By Walter Richter, Lewa

For safety reasons, odorants must be added to gases that are basically odorless, such as LPG (liquefied petroleum gas), in refineries and at loading terminals in order to detect leaks in pipes and equipment by smell. This task is performed by odorizing systems. When substances that contain sulfur are added, gases immediately become clearly perceptible to the human sense of smell. For its loading terminal on the southeast African coast in Mozambique, an international corporation required an odorizing system that can be used both on land and at sea. Since electricity is not available on the ships at the odorizing system’s installation site, a solution without electrical components had to be found. Spray water from strong waves and condensed seawater in the air also make systems corrode quickly, so that special protection was required. In order to avoid complicated dismantling and assembly work when changing location, the solution also had to be portable.

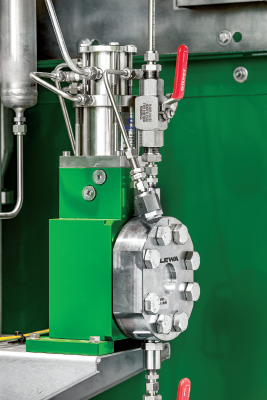

Lewa was commissioned with this task. The company is a long-standing expert for pumps and pump systems, that manufactures a wide variety of customized odorizing systems. For off-coast use, an offshore paint finish was added to the system to protect it against corrosion and at the same time, the current-free PKH compressed air pump was installed. Lewa also integrated the system into a cage so that it could be easily transported by crane.

EXPANDING THE LIMITS OF EXTRACTION

Worldwide more and more oil and natural gas is being extracted under conditions that are becoming increasingly extreme: for example, on the high seas or in the frozen polar sea. All plants and systems involved in their extraction must therefore be specially designed for adverse on-site conditions. This also applies to odorizing systems that add odorants to LPG, which consists of virtually odorless butane and propane. An international group that transships LPG at a loading terminal in Beira, Mozambique, wanted a suitable system for this purpose. The system needed to be usable both at sea and at the terminal itself.

After receiving the special order to supply an odorizing system for operation on land and at sea, the first task was to consider the different factors that are relevant for such an application. The main focus was resistance to seawater, the option to transport the system easily, and current-free system operation.

Since the system would also be used on board a ship, it first had to be integrated into a stainless steel cabinet to protect it from splash water and waves hitting the deck. To increase its corrosion resistance, it was also coated with offshore paint. Since the plant needed to be protected against salt water even when its doors are open, the integrated pump and drip pan were also coated with this paint.

PKH COMPRESSED AIR PUMP ALSO WORKS WITHOUT CURRENT

Due to the fact that there is no electrical power available at the installation site on the ship’s deck, a system without current-dependent components had to be worked out. This was mainly reflected in the choice of pump and the type of metering.

The PKH compressed air pump, a purely pneumatic unit which is designed for the gas flow of over 17,000 cubic feet per hour at 30 bar required on site, was installed. The odorant added to the LPG as it flows through is metered via a mechanically pre-set throttle valve with a fixed dosing rate, so that no electronic control is necessary.

The common additive ethyl mercaptan is used for odorization in this system. In the case of LPG, this chemical compound is preferable to the alternative THT (tetrahydrothiophene), as the latter mixes inadequately with the liquid gas. The odorant tank has a capacity of over 50 gallons. An additional lifting device can lift it out of the cabinet for filling.

LIFTING CAGE ENABLES CHANGE OF OPERATING LOCATION

Due to the customer’s requirement for using the system both at sea and alternately in a terminal on land, a lifting cage was also installed around the odorizing system. It enormously facilitates system transport, since neither dismantling nor cumbersome packaging is required for movement by crane.

All in all, the system can be used flexibly and is independent. At the same time, it is protected against adverse influences such as seawater. In addition, the plant was certified in accordance with the current international ASME standard. The odorizing system is to be installed by the middle of this year.

FOR MORE INFORMATION

Lewa GmbH was founded as a family company by Herbert Ott and Rudolf Schestag in 1952. Today, as a research and production-oriented company, Lewa develops technologies and provides solutions for the vast array of applications among its customers. Its products are used mainly in the oil and gas industry, in gas odorization, in refineries and petrochemicals, as well as in the production of plastics, detergents, and cleaners. Additional application areas include the chemical industry, cosmetics industry, pharmaceuticals and biotechnology, food and beverage industry, and energy utilities. For more information, visit www.lewa.com.

MODERN PUMPING TODAY, September 2020

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!