Based in St. Louis, Missouri, Emerson has been bringing technology and engineering together to provide solutions for customers in industrial, commercial, and consumer markets around the world for decades. The company’s five business segments (Process Management, Industrial Automation, Network Power, Climate Technologies, and Commercial and Residential Solutions) represent a wide range of resources and ideas that provide a foundation for innovations across a range of industries. Emerson’s Browning brand has made the latest contribution, introduced at last month’s AHR Expo, which improves the heat rating and durability for V-belts—even beyond what many technicians in the HVAC field thought was possible.

A NEW STANDARD

Browning introduced EPDM’s heat-resistance and durability advantages to all its raw-edge, notched V-belts at January’s AHR Expo, bringing an expanded temperature rating of -60 to 250 degrees Fahrenheit (-51 to 121 degrees Celsius) to AX, BX, CX, 3VX, 5VX and 8VX Gripnotch belts, some of the most commonly used V-belt cross sections in the HVAC industry. The EPDM formulated belts have a 110 degrees Fahrenheit (43 degrees Celsius) higher heat tolerance than industry-standard polychloroprene belts, making them ideal for rooftop blower units, commercial kitchen, or industrial process exhaust systems. “These belts will set a new standard for the industry,” says Don Sullivan, marketing manager for Browning.

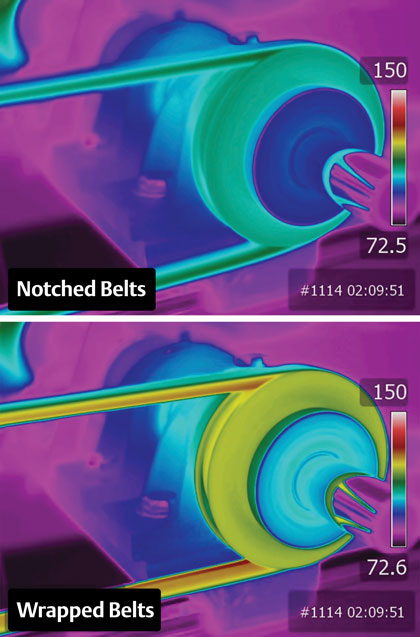

“Many technicians fail to account for the fact that a belt may reach 110 to 115 degrees Fahrenheit (43 to 46 degrees Celsius) while simply running in the sheaves at 72 degrees Fahrenheit (22 degrees Celsius) ambient temperature. If this heat is concentrated under a solid metal guard and the ambient temperature rises, it does not take long to approach the 140 degrees Fahrenheit (60 degrees Celsius) limit for common polychloroprene belts,” Sullivan adds. “On a rooftop in summer, even in northern climates, a V-belt drive can easily reach this critical temperature. Our EPDM formulation gives a much wider temperature window than polychloroprene – 79 percent wider. We originally introduced a limited offering of EPDM belts and due to popularity we expanded the offering to all notched belts and further developed the temperature range to 250 degrees Fahrenheit (121 degrees Celsius). This heat rating will be valuable in all applications and industries, but particularly in warmer climates.”

IMPROVED DRIVE EFFICIENCY

Browning’s notched V-belt styles can also improve drive efficiency 2 to 3 percent over wrapped style V-belts, saving about $300 per year on a 20-horsepower/15-kilowatt drive at $0.12 per kilowatt-hour. “U.S. Department of Energy DOE/GO-102005-2060 makes this recommendation, because in a typical commercial application with twenty identical air handling units of this size, a 3 percent energy savings at $0.12 per kilowatt-hour is about $6000 per year,” Sullivan explains.

“All these belts utilize a proprietary design that includes high fiber loading for long life, multiple plies of a unique tubular-woven knit fabric in the overcords for maximum flexibility, and wider notch spacing to increase rigidity and stability for lower stress at the cord line. They meet RMA (Rubber Manufacturers Association) standards for matched tolerances right off the shelf and are static dissipating, as well as oil and heat resistant. Coupled with the precision-ground edge for smooth, quiet operation, these raw-edge belts demonstrate how twenty-first century engineering and manufacturing can revolutionize a time-proven concept like the V-belt.”

SUPPORT ON THE GO

In addition to innovative technical details, Browning is also bringing new ways for technicians to gather and use data. Browning offers free mobile apps for efficiency calculation, selection, troubleshooting, and GPS locating of belt distributors. This spring, Browning will provide its HVAC Drive Kit Manager for iPhone and Android devices, a new feature of the Browning Toolbox Technician™ app, which allows users to access product information, track maintenance information from a phone or desktop, schedule future maintenance reminders, and share information between HVAC mechanical contractors and building owners. These features will utilize existing Browning belt drive kit labels on many HVAC unit control panels, so users should have a very small learning curve.

_______________________________________________________________________

ABOUT THE AUTHOR

Don Sullivan is the marketing manager for Emerson Industrial Automation—Power Transmission Solutions. He can be reached at don.sullivan@emerson.com. Emerson Industrial Automation, a business of Emerson, provides automation and power generation technologies and services to a wide range of industries. With its global capabilities and deep industry expertise, Emerson Industrial Automation is a trusted partner for products and solutions that increase machine performance, efficiency, reliability, and availability. For more information, visit www.emersonmovingconversations.com.

_______________________________________________________________________

MODERN PUMPING TODAY, February 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!