ANSIMAG pumps are specifically designed to handle aggressive corrosive or acidic liquids in chemical processing applications, including chlor-alkali, isocyanates, plastics and polymers, battery manufacturing, agro-chemicals, and a wide range of water and wastewater applications. To fill this need, Sundyne is expanding its ANSIMAG ALI (aggressive liquid ISO) family of ETFE-lined sealless magnetic drive pumps.

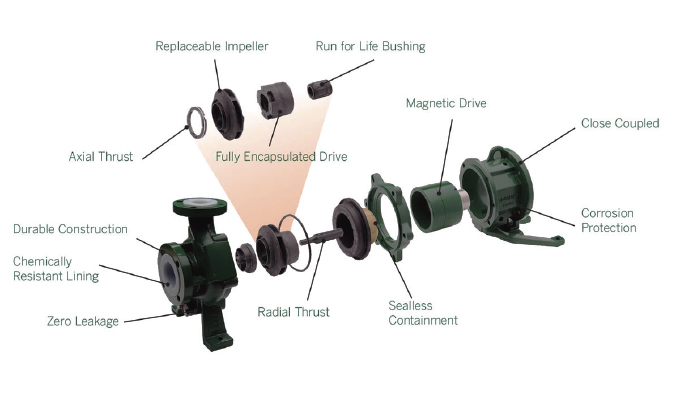

For those in the know, all ANSIMAG wetted parts are molded ETFE (ethylene tetrafluoro ethylene) components that can safely handle a wide range of corrosives and solvents. A patented, fully encapsulated magnetic drive hermetically seals the inner magnets to isolate them from process fluid and maintain magnet integrity for the life of the unit. An aramid fiber reinforced containment shell delivers unprecedented reliability and protection against water hammer.

WHAT’S NEW? EXPANDED CAPABILITY

The new ALI family brings all of the ANSIMAG benefits to ISO markets, supporting the dimensional requirements of ISO 2858 with specification conformity to ISO 15783. Eleven different ISO-compliant pump sizes provide flows up to nearly 37,000 gallons per hour, heads to 295 feet; temperatures from -22 to 248 degrees Fahrenheit (-30 to 120 degrees Celsius); and working pressures up to 19 bar.

The new ANSIMAG ALI line complements the extensive HMD CSI line of metallic sealless mag drive pumps. HMD CSI pumps support all ISO standards and feature various frame sizes to accommodate an even wider range of flow and pressure requirements at higher temperatures. The combination of CSI and ALI offers customers the widest range of reliable, sealless mag-drive options, in ETFE or metallic materials of construction, to address any chemical processing application.

UPDATED DESIGN

All ALI and HMD CSI pumps come with the worldwide backing of Sundyne’s global support network. Plus, ANSIMAG design features brought to ISO markets via the new ALI line include:

- Zero leakage: Sealless design completely eliminates possible leakage with only a single fully-contained O-ring.

- Chemically resistant materials: Carbon fiber reinforced ETFE is resistant to virtually all chemicals.

- Secondary containment: Especially beneficial for applications requiring an additional layer of protection.

- Corrosion protection: Powder-coated metallic parts provide excellent chemical resistance and superior impact/scratch resistance to maintain coating integrity.

- Durable construction: Ductile iron exterior is designed for heavy-duty chemical applications.

- Fully-encapsulated inner drive: Provides unsurpassed resistance to chemical attack by hermetically sealing the inner magnets and isolating them from the process fluid.

- Easy service: Nine wetted parts and a back pull-out design enables service without disconnecting the casing from piping and without requiring special tools.

- Close coupled: Completely eliminates the need for shaft alignment and bearing frame related maintenance in a smaller footprint.

- Energy Efficiencieny: Non-metallic materials completely eliminate eddy current generation allowing for greater efficiency.

BENEFITS YOU CAN TRUST

ANSIMAG ALI sealless mag-drive pumps provide affordable replacement options for aging ISO-sized pumps and the newly-expanded line covers a wide range of sizes and external dimensions to facilitate easy replacements without changing piping or baseplates

More than seventy years ago, HMD Kontro invented the magnetic drive pump, and today, the HMD CSI sealless pump line sets the standard for metallic magnetic drive ISO pumps. Since 1985, more than 50,000 ANSIMAG sealless, non-metallic mag-drive pumps have been deployed to handle harsh and corrosive chemicals in a variety of industries.

The introduction of the ANSIMAG ALI line brings a rich heritage to ISO markets, and the combination of ALI and CSI offers customers a one-stop-shop for sealless pumps to address any harsh and aggressive pumping application.

Colin Guppy is Sundyne’s global vice president of chemical and industrial. Headquartered in Arvada, Colorado, with operations and presence in Europe, the Middle East, India, Asia, Japan, and China, Sundyne is a global manufacturer of precision-engineered, highly reliable, safe, and efficient centrifugal pumps and compressors for use in chemical, petrochemical, hydrocarbon, hydrogen, pharmaceutical, power generation, and industrial applications. Sundyne is the world leader in delivering low-flow, high-head integrally geared centrifugal pumps and compressors, safe and leakage-free sealless magnetic drive centrifugal pumps, and diaphragm compressors. Sundyne pumps and compressors are also available in API, ANSI/ASME, ISO, and other industry compliant designs. For more information, visit www.sundyne.com.