By Pat Phillips, AutomationDirect

Pneumatics have been used in automated machines for well over 100 years, with pneumatic technology developing and evolving for over a thousand years in some form or another, for example as boat sails.

There have been many innovations over the years, and the basic pneumatic components such as valves, solenoids, cylinders, hoses, and fittings are well developed and mature. These devices can be combined in many ways to provide simple and reliable machine control.

This white paper examines pneumatic design best practices, and then presents four basic pneumatic circuits (see Table 1) commonly used in machine automation. While there are many variations, these pneumatic circuits combine basic pneumatic components to create functional and reliable pneumatic circuits.

PNEUMATIC DESIGN BEST PRACTICES

Before discussing these four basic pneumatic circuits, it’s best to review best practices for pneumatic design. While there is a long list of potential pneumatic problems such as low or varying air pressure, improper use of flow controls, air cylinders banging at power up, and slow or inconsistent cylinder speed—following good pneumatic design practices can address these and other issues.

Prerequisites for implementing pneumatic design best practices are an understanding of pneumatic circuit symbols, types of valves available, such as two-way, three-way, and four-way, pneumatic cylinders and related pneumatic components such as tubes, hoses, flow controls, and air preparation devices. A Practical Guide to Pneumatics is a good place to gain a basic understanding of these and other components and conventions.

The starting point for a good pneumatic design is ensuring proper plant supply air pressure. A consistent plant air pressure and flow is needed for pneumatic devices to operate consistently and reliably. Air preparation of the plant supply at the machine is important as well, and is the first basic pneumatic circuit discussed as follows.

To help control the air and the related motion of pneumatic actuators, the cylinder should not be oversized as this may cause it to stroke slowly due to excess air flow requirements. A properly sized cylinder provides more efficient use of air and moves at a higher speed.

A good design will include the use of flow controls to throttle the air exiting the cylinder, which slows down the cylinder motion, generally a desired outcome. The use of cylinders with built-in cushions also helps stop the cylinder at the end of travel. Both the flow control and cushions can help prevent banging and possible damage to the cylinder.

Actuators that move too quickly can cause excessive noise, as can the exhausting of air from valves. Using mufflers on the exhaust ports is a simple design practice that should always be followed to attenuate this noise.

AIR PREPARATION SUBSYSTEM

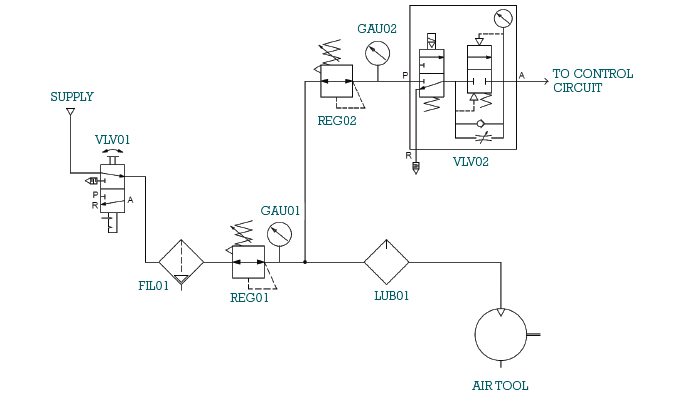

In terms of air flow, the first pneumatic circuit applied in most machines is air preparation. Plant-supplied compressed air needs to be prepped before it feeds air to any other pneumatic circuits on a machine. The air preparation circuit shown in figure 1 starts with a single-point pneumatic air connection, with its common components listed in Table 2. These devices often include a filter, regulator and, less often, a lubricator (FRL).

The order of the pneumatic devices listed in Table 2 is typically the order the devices are assembled in an air preparation unit, but not always. For example, some designs require a manual shut-off relief valve, VLV01, or a pneumatic isolation/lockout valve, to be the first component connected to the plant air supply. Others believe it should be mounted after an FRL to ensure clean, dry air flows through the valve.

This valve’s purpose is to remove or dump all of the compressed air from the machine. Releasing the air by rotating a manual valve or a push-pull action depressurizes the machine for maintenance, and, although not shown in figure 1, this manual valve should be lockable in the off position.

Mounting this shut-off valve upstream of the FRL enables maintenance of the FRL at the machine. Without it upstream of the FRL, filter maintenance would be difficult and could affect other equipment in the area when air is dumped for service. Additional plant level, area or zone air preparation and shut-off units can help protect the shut-off valve at the machine if necessary.

Filter FIL01 is used to remove particulates and separate moisture from the air, and it is mounted just downstream of the shut-off valve VLV01. This filter has a liquid drain, indicated by the triangle at the bottom of the symbol, that can be either manual, semi-automatic or automatic. The symbol does not show detail of the type of drain bowl, such as all metal or guarded. However, a schematic with a pneumatic panel layout drawing should detail this information, along with additional information such as mounting brackets.

Downstream of the filter is a regulator REG01, or it may be an integral part of the filter, which would be indicated by a dashed-line box around both filter and regulator. While not shown in the circuit diagram, it is good practice to note the working pressure of the machine and the maximum pressure allowed. A phenolic tag with this information is often attached near the regulator.

A pressure gauge, GAU01, should always be included with a regulator, either built-in or threaded into the pressure port typically included with the regulator. Often a pressure switch, not shown in Figure 1, is installed just downstream of the regulator for monitoring pressure okay status. This switch’s output is typically a discrete input to the machine controller, such as a programmable logic controller (PLC).

Regulators have input and output ports to ensure proper air flow, in some cases with a relieving feature. The relieving function reduces output air when the regulator is adjusted to a lower pressure. This function also ensures downstream pressure is removed when upstream air is exhausted. The regulator symbols, REG01 and REG02, show they are relieving type, indicated by the triangle at the upper left corner of each device.

The air exiting regulator REG01 produces clean, dry and filtered air that is then split through a tee fitting or a pneumatic distribution block, not shown. One branch provides a lubricated air supply, and the other a non-lubricated supply.

The non-lubricated supply feeds a second regulator, and then the electrically operated soft-start/dump valve VLV02. This valve typically removes air to motion-causing pneumatic devices such as cylinders and actuators for safety. These devices typically don’t need lubricating. When an emergency stop is pressed, power is removed from the valve, which causes it to dump the motion-causing air pressure from the system.

This air prep circuit diagram shown provides lubricated and non-lubricated air. Most pneumatic devices today do not need lubricated air, but if lubrication is needed, such as with pneumatic air tools and motors, it should be adjusted for light oiling because too much oil can clog up the pneumatic system components.

An all-in-one unit (such as the one shown in figure 2) can be used air preparation. It combines all the devices discussed in figure 1, less the lubricator, in one unit. It can be purchased from a vendor with a single part number, saving purchasing, receiving, assembly, and installation time. It also includes a clogged filter indicator, adjustable pressure switch with indicator LEDs, and adjustable port sizes to match the flow rate needed for an application.

A LOOK AHEAD

In next month’s conclusion, we’ll take a closer look at different circuit designs and the benefits they can provide to various applications and larger pneumatic systems.

FOR MORE INFORMATION

Siemens Digital Industries Software, a business unit of Siemens Digital Industries, is a leading global provider of software solutions to drive the digital transformation of industry, creating new opportunities for manufacturers to realize innovation. With headquarters in Plano, Texas, and over 140,000 customers worldwide, we work with companies of all sizes to transform the way ideas come to life, the way products are realized, and the way products and assets in operation are used and understood. For more information, visit www.sw.siemens.com.

Pat Phillips is product manager of fluid power and mechanical products for AutomationDirect. In business since 1994, AutomationDirect is a distributor offering thousands of industrial automation products for electrical control systems, including PLCs, operator interfaces, AC drives, motors, stepper systems, sensors, motor control, enclosures, and more. Their prices are typically well below the list price of more traditional automation companies because of their model and focus on efficiency, and the majority of their products are stocked for same-day shipping. For more information, call 800.633.0405 or visit www.automationdirect.com.

MODERN PUMPING TODAY, September 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!