Remote monitoring was once thought of as a solution restricted to critical pumping solutions in remote locations due to technology limitations and associated expense. But today, as technology and trends such as “energy management” have evolved, remote monitoring has become a prevalent solution in numerous applications, covering most end user markets including oil and gas, water/wastewater, commercial buildings, and even irrigation applications.

Two fundamental technologies have evolved, dependent on location, monitoring needs, and expense. The first is a SCADA based system utilizing powerful software and a broad range of communications options. The second is a cloud based solution, utilizing web based tools, and communications options such as GSM, WiFi, Cable Modems, DSL, and so on. Both have a major play in the pumping world.

SCADA BASED REMOTE MONITORING SOLUTIONS

SCADA software based remote monitoring is the traditional method for remote monitoring. In a SCADA System remote telemetry is only part of a larger facility control system. This solution utilizes powerful software running on PCs and or servers to store data and generate trends and alarms, update operator screens, etc. The data generated can be exported to spreadsheets and databases. Furthermore, these types of systems provide a gateway to enhance operational tools. For instance, in water and wastewater applications, pumping data can be combined with data from hydraulic models, GIS, energy monitoring, and laboratory information management systems to provide a complete overview on a group of easy to use dashboards.

Furthermore, the communications options are vast. For years, end users have used serial based protocols for communications. Today, many of these protocols have Ethernet equivalents. Remote monitoring systems can use phone lines, cable modems, DSL, GSM, GPRS, satellite, or dedicated radio such as the Schneider Electric Trio series. The choice depends on the application, geography, and the system designer’s preference. If a dedicated network is used, then the cost for data transmission can be eliminated. This can be advantageous for large systems.

As years have passed, experience within these systems has shown that remote monitoring has different needs than in-facility data monitoring. To respond to this a new protocol was created called DNP3. Most traditional protocols are register based and transmit a range of registers regardless if they have changed. Event sequencing is managed based on when the registers arrived at the host. DNP3 works differently; it only communicates what has changed since the last communication cycle, and when those changes occurred. This provides a means to retain data during communication losses, something that registered based protocols tend to poorly perform.

Furthermore, DNP3 has secure authentication and encryption tools that help address the concerns of cyber security. True remote telemetry units, understand the value of DNP3 in remote monitoring, and have adopted it.

While these systems are powerful, they require dedicated computers, software, field devices, and some form of remote communication. Often times, these need to be updated or maintained over the years to ensure continuous reliability. Cloud-based remote monitoring provides an alternative that has many advantages of its own.

CLOUD-BASED REMOTE MONITORING SOLUTIONS

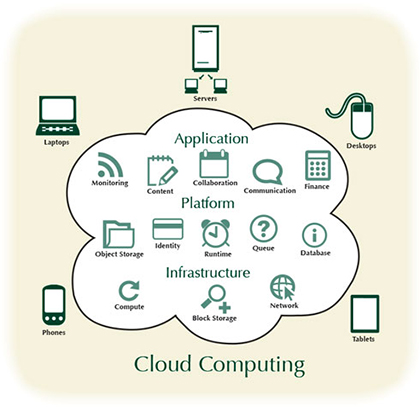

Cloud computing for remote monitoring is an excellent alternative method to the traditional SCADA systems in which software must be purchased, installed, and configured onto end user’s PCs and tablets. Likewise, access for these traditional SCADA systems is also limited to authorized devices running the software or mobile phone application. The typical business model for cloud computing is to use software as a service (SaaS), by providing authorized users access to application software and databases on cloud servers. Cloud-based systems allow end users to monitor remote pumping systems as well as transfer and store data in a high-security web cloud which is accessible via any device, anywhere in the world, with nothing more than an internet web browser.

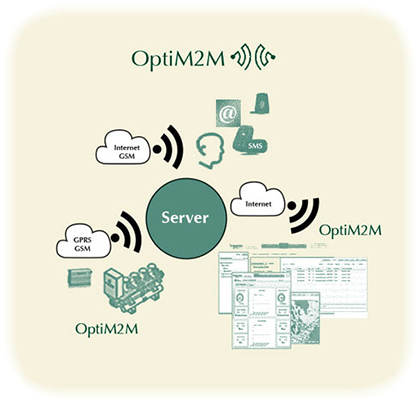

New solutions have come to market such as the OptiM2M™ remote monitoring offer from Schneider Electric, that facilitate a new type of go to market strategy where OEMs or pump skid builders can cost effectively provide remote monitoring of stand-alone pumping systems for themselves, their reps, and their end users. Solutions like these incorporate a GSM/GPRS modem that polls the pump system controller and delivers the data to the cloud. This allows the OEM to leverage and maximize their knowledge of their system to develop and deliver a comprehensive cloud based dashboard to monitor various parameters associated with pumping performance, energy efficiency metrics, preventive maintenance scheduling, and alarms.

Once the system is installed at the pumping site, the OEM can remotely monitor the pumping system, potentially resolving basic system problems that occur without dispatching onsite field services during a warranty period. Furthermore, charging a fee for end user access can provide a new revenue stream for OEMs interested in enhancing their value-added service offers. With the database residing in the cloud, the end user has the ability to review collected data such as daily energy usage and export the data to conduct performance analysis at their convenience. As these cloud based solutions, such as OptiM2M remote monitoring, make use of cellular networks, they can be deployed almost anywhere without the need of dedicated network hardware.

Today, pumping operators have many options for remote monitoring. While there are a variety of solutions available, they break down into two distinct options. The first is SCADA software based and the second is cloud-based. Once this method has been determined, the rest of the options quickly fall into place. Both offer distinct advantages and the possibility for years of reliable service. ■

_________________________________________________________________________

ABOUT THE AUTHORS

Grant Van Hemert, P.E., is Schneider Electric’s remote telemetry product manager. Grant’s previous experience in water and wastewater as well as remote telemetry dates back to 1995. George Caudle is the solutions marketing manager for the OptiM2M remote monitoring solution for Schneider Electric. He can be reached at george.caudle@schneider-electric.com or 919.332.0823.

_________________________________________________________________________

MODERN PUMPING TODAY, April 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()