By Dave Johnston, Mueller Water Products

Water-industry press naturally covers the broadest and brightest promises of the digital revolution. Unfortunately, that big-picture view can often intimidate or mislead small- to medium-size utilities who interpret it as demanding a large investment to reap the benefits. Here are some insights into how utilities of any size can affordably harness the value of timely digital data from their distribution systems.

FULFILLING THE PROMISE WITHOUT OVERDOING THE INVESTMENT

With the right sensors and systems, utilities can start realizing the benefits of digitalization—saving money, extending the life of existing infrastructure, and making better informed operational decisions—without having to make an all-or-nothing investment.

First, utility water-resource and asset managers can use such systems to improve reliable data collection from the field, minimize distribution system breaks and non-revenue-water (NRW) losses, improve asset management, and extend asset life. Also, financial personnel can use their data for budgeting, capital planning, asset valuation, financial performance analysis, and public outreach. Finally, contractors can also leverage that data to project work schedules, monitor equipment status, and budgeting future projects.

DEMYSTIFYING DIGITAL-TECHNOLOGY MYTHS IN WATER DISTRIBUTION

Here are four myths that can be shattered with just a modest initial investment in the right technology:

1. Digital technology is only for large utilities.

Advancements in sensors, sensor placement, and cloud-based management platforms have made the cost, accessibility, and implementation of pressure and leak detection technologies more affordable than ever. Cloud-based solutions make data access and analytics as readily accessible as any smartphone app.

2. Digital technology is too expensive.

Easy-to-retrofit solutions minimize the cost of installation and eliminate the need for special skilled labor. They often surprise new users in how quickly they achieve their return on investment by simply monitoring a few hydrants for operating pressure/leaks throughout the system.

3. Smart hydrants require full-system replacement.

Only a select number of hydrants need to be equipped with sensors, and even those can be existing hydrants.

4. Acoustic technology is unreliable “black magic.”

In just the past five years, the accuracy behind acoustic leak detection has improved by 50 percent. Some technologies, like Echologics, are now achieving 74-percent classification accuracy (i.e., 74 percent of events labeled as leaks are, in fact, leaks). New technologies in development are scheduled to improve that to 93-percent classification.

The good news is that leak-noise-correlation technology has advanced so far in recent years, that even small installations can benefit enough from early leak detection and resulting savings to pay for the investment in as little as a year.

A QUICKER, MORE AFFORDABLE PATH TO DIGITAL PRODUCTIVITY

As impressive as acoustic leak sensing and pressure monitoring have been for cutting NRW losses, small- to medium-size utilities want solutions that can scale down to their unique budget and physical requirements, without sacrificing the ability for a quick payback. Newer retrofit capabilities are doing exactly that.

Easy-to-retrofit Hardware

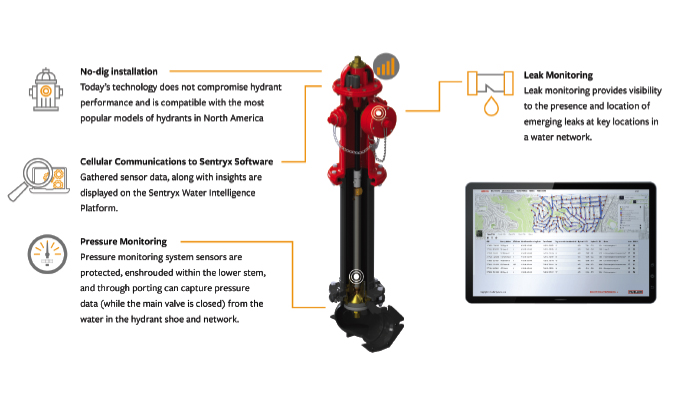

Having affordable sensor and communication configurations that can be added to existing hydrants, like the Mueller dry-barrel Super Centurion or wet-barrel Jones hydrants in an hour or two—without excavation headaches or attendant costs, and without compromising functionality—are important considerations for easy retrofit applications.

Multi-purpose Capabilities

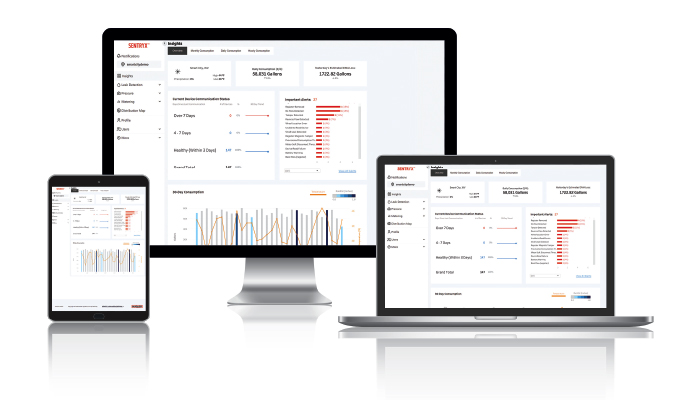

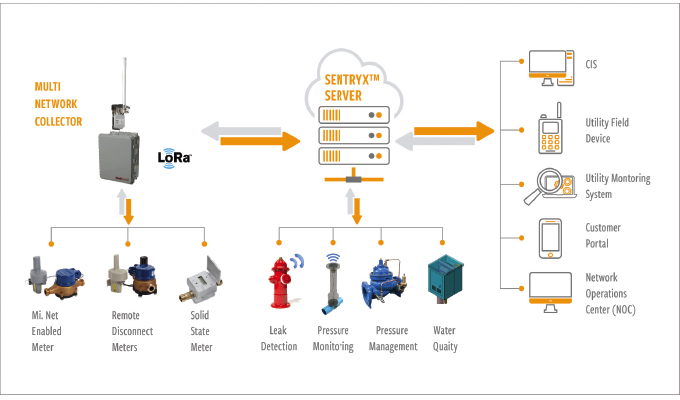

Individual fire hydrants can house state-of-the-art pressure monitoring and leak detection sensors that communicate data to a scalable network monitoring platform like Sentryx, via cellular signals. The hydrant becomes a communications hub for the entire water distribution system. Being able to access that network platform from any web-accessible device enables all utility employees to benefit from timely data being collected.

Multi-parameter Analytics

Being able to combine flow data from residential water meters along with leak-detection and pressure readings from distribution system sensors gives distribution managers greater ability to understand what is happening than each individual reading does. For example, acoustic leak detection can identify and track slow-growing leaks that start small, while pressure monitoring does a better job of detecting sudden bursts. Analyzed together, they can help water distribution utilities have a better appreciation and understanding of system changes and of developing problems over time. Be sure to incorporate pressure sensing that can automatically capture the detailed data needed to document transient pressure-spike problems when they suddenly occur.

Improved Insights

Having the status of all sensors monitored by a network operations center with individual readings readily available through a web-accessible dashboard gives utilities 24/7 confidence in system visibility. This can be done in-house or some manufacturers like Mueller will offer to oversee for you. This provides the opportunity to monitor suspicious signals, tend to small leaks proactively before they become big problems, and respond to pipe-burst emergencies before they trigger boil-water advisories. It also enables early identification of NRW losses and managing of aging infrastructure assets more cost-effectively through the best combinations of leak detection and monitoring, pressure relief valve operation, and advanced metering infrastructure.

Experienced Consultation

Even with the right hardware, it is important to know how to configure it for optimal insight into distribution system performance. Consulting a knowledgeable supplier experienced with factors such as system age, water main materials, elevation changes, and operating pressure profiles can all impact ideal sensor placement for the best insights into systemwide performance.

GETTING STARTED

Exploring the ability to retrofit leak-detection and pressure monitoring into a small system or a controlled segment of a larger system does not have to be expensive or time consuming. It is often easiest to start with a pilot project for proof of concept to monitor performance and calculate payback benefits in a problematic neighborhood before rolling out to the entire utility infrastructure. Requesting a demo of a small-system pressure and leak-detection solution including guidance on sensor placement for optimum efficiency within the infrastructure is an ideal first step for calculating available efficiency gains and cost savings.

Dave Johnston is director of smart infrastructure for Mueller Water Products. Mueller Water Products is a leading manufacturer and marketer of products and services used in the transmission, distribution, and measurement of water in North America. The company’s broad product and service portfolio includes engineered valves, fire hydrants, metering products and systems, leak detection, and pipe condition assessment. It helps municipalities increase operational efficiencies, improve customer service, and prioritize capital spending, demonstrating why Mueller Water Products is “Where Intelligence Meets Infrastructure.” For more information, visit www.muellerwaterproducts.com.

MODERN PUMPING TODAY, June 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!