To maintain a leadership position amid rapidly changing pelletizing techniques and pellet forms, a manufacturer must be founded on state-of-the-art technology and on comprehensive know-how. Automatik Plastics Machinery has built a longstanding tradition in development, production, and global sales and distribution. The company’s latest offering, Primo 200E, is a new single-side mounted dry-cut strand pelletizer with an extra-large cutting width of 7.87 inches (200 millimeters). Primo 200E combines a broad range of skillfully designed product features delivering user friendliness and productivity.

HIGH MARKS FOR UNIQUE CUTS

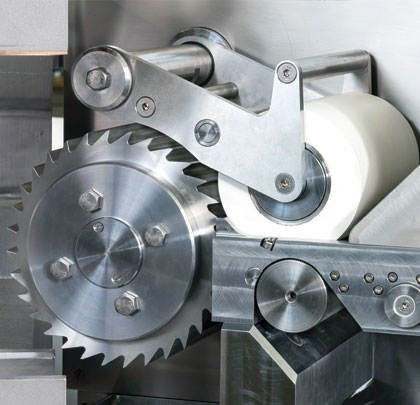

Among single-side mounted strand pelletizers the Primo 200E scores highly thanks to its unique cutting geometry with the shortest unguided length between the feed rolls and the cut. This geometry enables optimum straight cutting of both hard and very soft plastic strands, all in top quality.

The Primo 200E is particularly suitable for compounding of thermoplastics, for functional and additive masterbatch production and for the production of color concentrates up to a line throughput rate of 1.65 tons (1.5 tonnes) per hour.

Primo 200E

VERSATILE CUTTING

Highlights of the Primo 200E are its cutting tool sets for hard, abrasive and soft, flexible plastics. The pellet dimensions can be quickly changed by means of an optional automatic pellet length adjuster. This is done using a second drive motor for the feed mechanism with an integrated speed control.

When processing abrasive products and at high production temperatures, the Primo 200E can optionally also be equipped with a separately driven, highly wear-resistant metal feed roll instead of the standard elastomer feed roll.

The design of the Primo 200E makes it an outstanding choice for the efficient production of micro-quantities of color master batches and concentrates. It is easy to clean, features a low-deposit cutting chamber and enables short retooling times, and the cutting and tool changing process is likewise quick and easy.

CASE STUDY: GABRIEL-CHEMIE GROUP

The Gabriel-Chemie Group specializes in dyeing and finishing plastics. The company was founded in 1950, and today is one of Europe’s leading master batch manufacturers. The privately owned independent concern is based in Gumpoldskirchen, Austria. It operates subsidiaries in Germany, the United Kingdom, Hungary, the Czech Republic, and Russia. Having just launched the product in 2013, Automatik Plastics Machinery sold the first three units of its new Primo 200E strand pelletizer model to Austrian master batch manufacturer Gabriel-Chemie GmbH.

After a short test phase with a trial machine, Gabriel-Chemie found the decision easy. The Primo 200E delivered outstanding pelletizing quality and high levels of user-friendliness, while its ease of handling for batch changing made cleaning and retooling much quicker, enabling significant savings to be made in production. The Primo 200E received further plaudits thanks to its deposit-free cutting head design, compact size, and low running noise.

MAXIMUM RELIABILITY

Automatik Plastics Machinery places the greatest value on maximum reliability, and that commitment is reflected in the strong and rugged design of this cantilevered pelletizer.

Another special feature of the new machine is that the feed geometry is designed without major deflections, so the plastic strands are not subjected to pre-tensioning prior to cutting. This means that even highly fragile polymers such as polystyrene or highly filled master batches can be pelletized in high qualities, nearly without longs or dust.

A NEW APPROACH FOR THE NEXT GENERATION

Automatik Plastics Machinery actively seeks to help customers with new developments to enhance production efficiency and make their operations run more energy-efficiently, as well as offering retrofit options to upgrade machine versions. This approach extends machine service lives, meaning use of energy and commitment of other resources is delayed and ultimately reduced—because the next generation of pelletizing machinery will incorporate further updated production strategies to make them even more efficient.

This next generation of machines will be built by a new generation of staff who will in turn be able to call upon a reservoir of ideas accumulated by Automatik Plastics Machinery over many decades in the form of its extensive portfolio of patents. Some twenty to thirty patents are registered every year, ensuring that Automatik Plastics Machinery—despite being a medium-sized manufacturing company—is able to retain its position as the world market leader in its specialist field of thermoplastics pelletizing. ■

ABOUT THE AUTHOR

Ruth Ploch is the marketing manager for Maag, a worldwide leading manufacturer of gear pumps, pelletizing systems, and filtration systems for demanding applications in the plastics, chemical, petrochemical, and food industries. Its subsidiary Automatik Plastics Machinery has been manufacturing innovative pelletizing systems of the highest quality for several decades. It is the world leader in underwater strand pelletizing systems. She can be reached at ruthploch@maag.com.

_________________________________________________________________________

MODERN PUMPING TODAY, January 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()