Keeping 1.2 million fish per year alive is no easy task,” says Ted Hallows, supervisor at Kamas State Fish Hatchery, Utah. Whirling disease, a serious issue many fish hatcheries are faced with, is especially familiar to Kamas Fish Hatchery. When the entire fish inventory was recently threatened with whirling disease contamination, the only solution was to install an improved water treatment program in the form of a VAF Filtration Systems (VAF) pre-treatment filtration and ultra-violet technology system. The new installation has provided the hatchery with effective protection against the potentially fatal fish disease.

CONTAMINATION RISK

Kamas State Fish Hatchery, located three miles southeast of Kamas in Summit County, Utah, produces mainly trout to stock much of the state’s water sources. In 2010, a sinkhole was discovered about ¾ of a mile above the hatchery. Evidence of whirling disease had been found in Beaver Creek located near the sinkhole, and there was concern that the proximity of the sinkhole to the contaminated water could potentially cause “mixed waters” in the local springs used by the hatchery.

A whirling disease outbreak and possible loss of the entire fish inventory was not something Kamas was willing to chance. Whirling disease, causing fish to swim in unnatural patterns and eventually leading to death, is taken very seriously by hatcheries so there was no choice but to temporarily close Kamas down until preventative measures were in place. To avoid the risk of contamination, a combination of VAF pre-treatment filtration and an application of UV light was selected and installed.

V-SERIES FILTERS INSTALLED

Kamas Hatchery, successfully re-opened in 2013, was outfitted with a two-stage filtering system. Five VAF V-1500 Series filters remove total suspended solids down to 25 micron, providing efficient pre-treatment for the UV technology.

Three canisters of 40 UV lights kill bacteria and parasites during the second stage of the new $1.3 million filtering system. When correct UV doses are applied, the micro-organisms are inactivated and cannot reproduce. The delivered dose is the result of the UV light intensity emitted by the lamps and the exposure time of the water. The system, now in operation for about eighteen months, is designed to handle up to 3000 gallons (11,356 liters) per minute of incoming source water but currently averages about 2300 gallons (8706 liters) per minute. The use of UV technology in combination with pre-treatment filtration is in place at three other Utah state hatcheries.

SIMPLE SOLUTION WORKS BEST

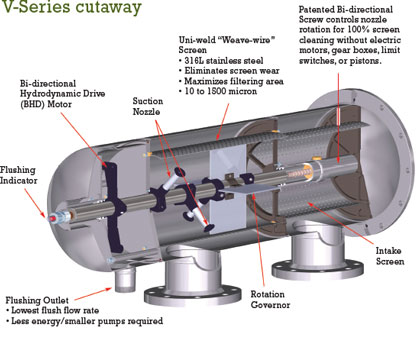

“We have been very pleased with how the new system is working, and we like the simplicity of the filters,” Hallows remarks. The patented Bi-directional Hydrodynamic (BHD) drive design of VAF’s filters allows for 70 percent fewer moving parts than other similar screen filtration technologies and does not require electric motors, limit switches, gearboxes, or hydraulic pistons. Furthermore, there are no external shafts or seals that could be potential leak points. As a result, there are inherently fewer problems and less maintenance. The flush waste is also less than 1 percent of the system flow with no interruption in flow or the filtration process while cleaning.

The project designed by Sunrise Engineering was quite extensive including site and plant piping, electrical work, pump vaults, and modifications to the existing hatchery shop building to accommodate the new treatment equipment. The Kamas system includes several emergency backups and a modified recirculation system which has increased the source waters and in turn, increased production at the hatchery. Battery backups and redundancy in the filtration system ensure the safety of the fish at all times.

The existing feed-water lines from spring waters were intercepted and connected via new piping to a new feed-water pump station vault. One operational and one redundant vertical turbine pump was installed with a design flow for the feed-water pump station of 5 cubic feet (141.5 liters) per second. Water from the feed-water pump station is pumped into the existing shop building and through an automatic self-cleaning filter, into the closed vessel UV modules and then exits the building.

VAF V-series filters installed at Kamas.

PLAYING A VITAL ROLE

VAF filters have a vital role in preserving the health of the fish at Kamas by providing a level of pre-treatment essential for the UV application. However, the use of pre-treatment is a necessity in numerous other designs and applications such as reverse osmosis, cartridge, membrane, and other micro-filtration technologies.

VAF’s unique advanced systems include individual, modular, and skid-mounted automatic self-cleaning filtration systems, all manufactured in the US. The VAF V-Series filters can remove suspended solids from 1500 to 10 micron. VAF provides both individual filters and pre-assembled systems to meet any flow demand. VAF filters qualify for LEED points as the V-Series design provides energy and water savings over conventional filters that use electrical motors and thousands of gallons to flush. ◆

For thirty years VAF Filtration Systems has been providing filtration solutions worldwide with a business model built on simplicity, quality, and integrity. VAF filters qualify for LEED and ARRA funding—as all materials, manufacturing, and assembly are done in the United States. For more information, call 303.425.4242, email sales@vafusa.com, or visit www.vafusa.com. To see the filter in action, visit www.vafusa.com/dvd.

____________________________________________

MODERN PUMPING TODAY, May 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()