In November 2015, the Air-Conditioning, Heating, and Refrigeration Institute released an updated “Standards for Performance Rating of Liquid to Liquid Heat Exchangers,” for the testing, rating, and marking of such products used in the HVAC industry. The standard ensures all manufacturers are designing to the same tolerances, providing a reliable “apples to apples” comparison of equipment. It’s important for HVAC system designers to know the basics of AHRI Standard 400 to be sure they are specifying reliable, high-performing equipment.

1. WHAT IS AHRI?

AHRI is a trade association with 300-plus member companies that produce more than 90 percent of the air-conditioning, heating, water heating, and commercial refrigeration equipment made in North America. AHRI strives to promote energy savings, improve productivity and ensure a better environment. AHRI certification programs establish definitions, minimum data requirements for published ratings, marking/nameplate data, test requirements, and conformance conditions.

2. WHAT IS THE AHRI STANDARD 400 FOR LIQUID TO LIQUID HEAT EXCHANGERS?

The AHRI Liquid to Liquid Heat Exchanger (LLHE) program, now formally ANSI/AHRI Standard 400 (formerly ARI Standard 400), is a third-party certification program that attests to the performance of gasketed plate heat exchangers designed to transfer heat from one single phase fluid to another in an HVAC system, using actual third-party witnessed laboratory testing.

3. WHAT TOLERANCES DOES AHRI REQUIRE THE MANUFACTURER MEET DURING ITS PERFORMANCE TESTING?

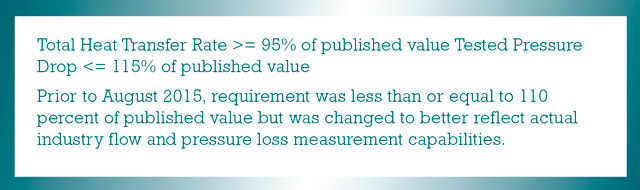

AHRI developed testing requirements more stringent than those traditionally used in the HVAC industry to recognize the use in high-energy-efficient solutions with close temperature approaches and high-efficiency pumps. During testing intervals specified by AHRI, the manufacturers stated performance for a given test must meet the following requirements.

4. HOW IS AN HVAC SYSTEM DEFINED?

In the ANSI/AHRI Standard 400 LLHE Operations Manual HVAC is defined as “applications encompassing equipment located in a residential or commercial building exclusively used for conditioning spaces for the occupants of the building.”

5. WHAT IS THE SCOPE OF THE ANSI/AHRI STANDARD 400 PROGRAM?

The scope of the ANSI/AHRI Standard 400 program is defined as:

- For gasketed plate type heat exchangers.

- Utilizing water or sea water (glycols are not yet included).

- With a capacity less than or equal to 24,000,000 btu/hr.

- And flow rate less than or equal to 2,000 gpm (as of April 2016 flow rate increases to 20,000 gpm and 240,000,000 btu/hr).

6. WHAT IS THE INTENDED MARKET?

AHRI defines the intended market of the ANSI/AHRI Standard 400 program as the United States, U.S. Territories, and Canada.

7. WHY IS AHRI STANDARD 400 IMPORTANT?

AHRI certification ensures a manufacturer’s stated product performance will be met and operate as designed, thus enhancing buyer confidence.

- Ensures all manufacturers are designing to the same tolerances, providing buyers a reliable comparison of equipment.

- Promotes energy savings. For example, in a “free cooling/waterside economizer” application, this could mean the chiller will run less, resulting in energy savings.

- Other pieces of equipment in a system, such as the chiller, may have AHRI or other certifications (CTI for cooling towers, for example).

- AHRI certification can facilitate compliance to various state and federal efficiency regulations.

- ASHRAE Standard 90.1 requires waterside economizers to comply with AHRI Standard 400 beginning with 2010 version.

- U.S. Green Building Council’s LEED program references ASHRAE Standard 90.1.

International Energy Conservation Code registers compliance with ASHRAE Standard 90.1. - Most AHRI certification programs, including AHRI Standard 400 for liquid-to-liquid plate and frame heat exchangers, require members to quote an AHRI-certified model/design when the application is within the scope of the program.

- Most of the major plate and frame heat exchanger manufacturers have worked to developed to this standard.

8. WHAT ARE “CERTIFY ALL” REQUIREMENTS OF AHRI?

Almost all AHRI certification programs, including the Liquid to Liquid Heat Exchanger AHRI Standard 400, have a “certify all” requirement.

- Certify all requires any manufacturer that has its AHRI certification for the product to quote and provide an AHRI-certified design when the application falls within the

- AHRI program scope, application definition, and intended market.

- The scope, application definition, and market are defined above.

- The certify-all requirement is necessary regardless if the specification, user, buyer, etc., requires an AHRI certified design or not, and applies to all participating manufacturers of the AHRI certification program.

9. HOW DOES ONE SPECIFY GASKETED PLATE HEAT EXCHANGERS BASED ON THE ABOVE INFORMATION?

If writing a specification, it is recommended to add clarification to avoid any interpretations or opinion. This will help ensure “apples to apples” comparisons.

- Specify that acceptable manufacturers are:

° Certified participating members of the AHRI.

° Liquid to Liquid Heat Exchanger Certification Program based on ANSI/AHRI Standard 400. - Manufacturer must have AHRI LLHE certification to offer an AHRI certified model.

A manufacturer can be a member of AHRI but not participate in or have AHRI LLHE certification, hence should not be considered equivalent to members with AHRI LLHE certification. - Statements such as “in accordance with,” or similar, are not the same as AHRI certified.

- If the application is within the AHRI scope, meets the AHRI definition for HVAC equipment, and is being sold into the intended market:

° Require an AHRI certified model to be listed in the schedule. - If the fluids or heat load or flow rates are outside the scope of the AHRI LLHE certification program, add clarification to the specification that:

° Accepted manufacturer must have AHRI LLHE certification, even though model offered cannot be AHRI certified due to being out of scope.

° Manufacturer must design to the tolerances required in AHRI Standard 400 for heat transfer and pressure drop.

HOW CAN I TELL IF A UNIT IS AHRI CERTIFIED?

The certified manufacturers are required to attach the label shown below for all certified units. Bell & Gossett continues to be an active certified member of the ANSI/AHRI Standard 400 for Liquid to Liquid Heat Exchangers. Working with AHRI, development continues to expand and improve the program to support energy savings, improve productivity, and ensure a better environment. ◆

For More Information:

John Boyer is the heat transfer market manager at Xylem Inc. He holds a bachelor of science degree in chemical engineering from the University at Buffalo and Six Sigma Green Belt certification, Lean, from the University of Michigan College of Engineering. For more information, visit www.bellgossett.com.

____________________________________________

MODERN PUMPING TODAY, July 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()