Last month, we outlined the sealing challenges facing one of the most state-of-the art chemical facilities in Europe, the TOTAL refinery at the Leuna chemicals site—Germany’s largest manufacturer of methanol as well as a producer of LPG, untreated gasoline and jet fuel, diesel, heating oil, and bitumen.

Faced with numerous failures and very short MTBF with their existing setup, the operator asked EagleBurgmann to develop a permanent and reliable sealing solution. Just a few months later they were able to present their innovative solution: the DF-MFLWTI with inserted seal face.

INNOVATIVE CONCEPT: DF-MFLWTI WITH INSERTED SEAL FACE

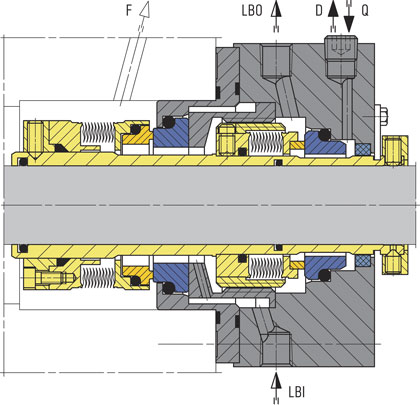

EagleBurgmann’s design solution is based on the proven metal bellows design. As metal bellows do not need elastomer secondary seals, they are the perfect candidate for application at high temperatures. The MFLWTI is a double seal in tandem arrangement and is supplied ready for installation as a cartridge unit. It is supplied unpressurized to API Plan 21+52+61.

The innovative key element of the MFLWTI is the loosely inserted face of the seal on the product side, combined with the DiamondFace diamond coating of the contact surface. Even the choice of material for the seal face highlights its flexibility: the inserted ring offers more options in this respect than shrink-fit faces. It also impresses with its positive deformation behavior in operation and, as it is able to move, it will not tilt or cant.

The diamond coating makes the seal immune to dry running and solids in the medium. EagleBurgmann DiamondFace has already proven its worth in numerous applications in the oil and gas industry, refinery engineering and power station technology, for example. Minimal friction, practically no wear and maximum chemical resistance—with the DF coating from EagleBurgmann, previously unachievable operating periods and MTBF or MTBR intervals are now possible, even under difficult conditions.

EagleBurgmann tandem mechanical seal DF-MFLWTI. The seal on the product side has a loosely-inserted, diamond-coated seal face. (Yellow parts rotating, blue stationary. Gray: Pump shaft and housing.)

SUCCESSFUL CONVERSION, INCREASED PRODUCTIVITY

Since conversion to the newly-developed EagleBurgmann DF-MFLWTI metal bellows seal with DiamondFace coating in 2013, the pump and seal have been running at TOTAL Leuna continuously and without complaint with regular start / stop cycles caused by scheduled switchover to the parallel pump. Plant availability has been significantly increased as a result. Given this excellent experience, TOTAL Leuna has now decided to retrofit this sealing solution in the parallel pump as well.

GROUNDBREAKING SOLUTION FOR THE FUTURE

The customer-specific sealing solution illustrated here sets new standards in terms of product development. The design principle of a metal bellows seal with inserted seal face is currently under development to the series production stage in the new EagleBurgmann MFLWTI series.

In the future, there will be MFLWT(I) seals available with or without DiamondFace coating for use at temperatures up to approximately 752 degrees Fahrenheit (400 degrees Celsius) and pressures up to 25 bar (363 PSI).

For More Information

Robert Rusp is product manager for mechanical seals for pumps at EagleBurgmann. With a pronounced understanding for quality and service as well as customer orientation, EagleBurgmann draws on its knowledge and expertise to provide local support to customers and solve their problems quickly and efficiently. For more information, visit www.eagleburgmann.us.

____________________________________________

MODERN PUMPING TODAY, March 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!