Components of electrical machines are subject to thermal, electrical, ambient and mechanical stresses leading to degradation as materials lose strength over time. Condition monitoring can detect premature failure and extend the life of the machine. Rotating machinery critical to the process chain including AC/DC motors, turbines, fractional horsepower motors, VFD controllers, SCR controllers, and generator exciters should be continuously monitored to detect impending failures. Energy distribution networks are highly dependent on transformers, failure of equipment or surrounding components can lead to blackouts or catastrophic shutdowns. Any change in machinery performance including vibration, temperature, or current draw should be further examined to ensure continuous operation.

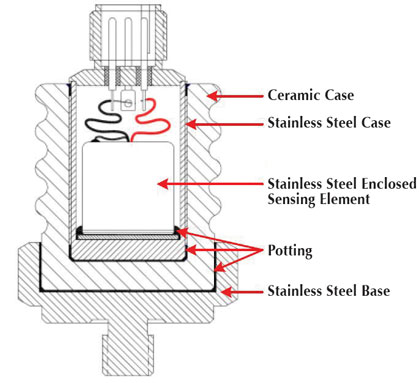

Figure 1: Internal components

BENEFITS OF VIBRATION MONITORING

Vibration monitoring of crucial equipment can help detect a variety of machinery faults including looseness, imbalance, and misalignment. Bearing and lubrication issues can be resolved before causing damage to internal components. Monitoring machinery located in close proximity to wind turbine generators or VFD/SCR controllers requires instrumentation capable of withstanding high levels of electromagnetic interference (EMI) and electrical fast transients (EFT). High voltage, high electric and magnetic fields can cause strong EMI, vibration sensors mounted in industrial environments should be able to operate without damage or risk of degradation. Rugged design and high performing components ensures reliable operation in harsh industrial environments without communications loss or delays.

THE NEED FOR HIGH VOLTAGE SENSORS

Most accelerometers are suitable for hot and humid industrial environments, but can fail when exposed to high transient voltages. High voltage (HV) series accelerometers are immune to electrically noisy environments by providing extraordinary EMI and EFT protection and high electrical isolation between the sensor circuitry and the machine.

HV sensors use a material with high electrical resistance and high breakdown voltage which provides the necessary electrical insulation between the mounting surface and the accelerometer’s case and connector. The sensor casings are a ceramic material much like the type used for insulators on high voltage power lines. Inside the high voltage ceramic outer case, which serves as an isolator, the internal accelerometer is housed in an EMI absorbant, Mu-metal case, providing additional support to the ceramic structure. Internal potting adds further isolation and improves the frequency response of the sensor, making it comparable to standard sensors (see figure 1). Since the majority of vibration sensors utilize stainless steel outer casings, the new ceramic material was fully tested to ensure equal durability in the field. The sensors passed a 500 pound (226.8 kilogram) pull-strength test confirming the survivability of the potting and ceramic material under severe stress conditions.

SHOCK SURVIVABILITY

Without insulator cups, typical sensors have a nominal resonance of 30 kHz. The addition of the insulator cup drops the resonance frequency of the HV sensors to 25 kHz. The effect on the frequency response is minimal when making measurements on typical machinery, with no difference in the ±5 percent response within the amplitude range.

Shock survivability was considered during the design process to ensure reliability in harsh environments. The shock limit of HV sensors is specified to 2000 g peak. To demonstrate the strength of the ceramic insulator, sensors were subjected to a series of shock pulses up to 8500 g peak through the sensitive axes during the development phase. No cracks developed in the ceramic cup, proving suitability as industrial grade sensors.

ARC PROTECTION

Arcing can occur when high potential is separated by a non-conductive material, like in a capacitor, and the breakdown voltage is exceeded. HV sensors are designed with connectors that utilize a high withstand voltage dielectric to prevent arcing between pins and pins to the shell, offering better protection of associated equipment. The new design employs a cup that holds the ceramic insert. A high dielectric potting material between the ceramic cup and stainless steel cup adds to the overall performance of the sensor (see figure 1).

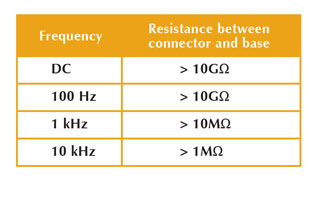

Testing was conducted to determine the withstand voltage between the accelerometer’s mounting surface and the connector. Up to 6000 volts DC and 5,000 volts AC were successfully applied between the connector and the accelerometer’s base for a period of one minute. Impedance measurements were made between the connector and base (see Table 2).

A protection circuit helps protect against damage from EFT and Electro Static Discharge (ESD) events induced through the accelerometer’s cable. ESD events often occur during installation, commissioning or servicing of monitoring systems. While proper ESD precautions are always recommended, the built-in protection circuit can help prevent failures due to transient events. Laboratory testing confirmed that no damage to the sensor occurred when exposed to EFT and surge levels of 6000 volts, and ESD levels up to 15,000 volts.

SHIELDING FOR CLEAR SIGNAL TRANSMISSION

Motors and generators are often located next to or near instrumentation cable trays. EMI and Radio Interference (RFI) can interfere with signal transmission causing data errors. These cable runs provide a path with a means to store charge through the wire capacitance. Some monitoring systems may use up to 1000 feet (304.8 meters) of wire between the sensor and data access point. To reduce interference, shielded cables and connectors should be used with high EMI resistance sensors to ensure reliability of data.

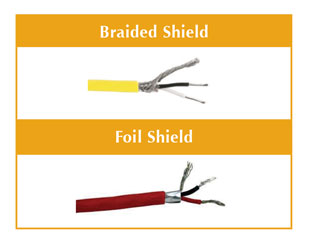

Two primary types of shielding are available for high EMI environments: braided wire or foil shielding. Foil shields are typically used with high frequency signals within electronic circuitry. They can be used in machinery health monitoring applications however the effectiveness of the shield can be compromised by the strength of the RFI. Foil shields also provide poor isolation of low frequency signals such as ground loop interference.

Braided shields offer up to 95 percent shielding of signal carrying conductors. The wire gauge and tightness of the weave determines the effectiveness of the braided shield. The mass of the braid is higher than a foil shield, offering better conductivity to ground and secure connections at the terminal blocks.

CONCLUSION

When monitoring vibration in high EMI environments, it is important that sensors output reliable data over time. Monitoring equipment should be able to endure conditions that can include extremely strong electric and magnetic fields. Standard industrial accelerometers can suffer severe failures in such environments. By employing sensors specifically designed with high EMI resistance, failure and replacement can be avoided. Severe interference can cause erroneous data and misinform personnel about the true nature of machinery health. Employing long-lasting and durable monitoring solutions helps ensure the reliability of the entire industrial process, maintaining continuous output and eliminating unnecessary downtime. ■

About The Author

Shalvi Desai is marketing communications specialist and Renard Klubnik is product manager for Meggitt Sensing Systems, a recognized leader in supplying high quality, cost effective predictive maintenance equipment including vibration monitoring sensors and transmitters, accelerometers, signal conditioners, hazardous area sensors and related equipment. For more information, call 301.330.8811 or 800.WILCOXON, email wilcoxon@meggitt.com, or visit www.wilcoxon.com.

MODERN PUMPING TODAY, April 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!