In industrial installations, process plants are designed to minimize floor space. Abbreviated floor space can result in inadequate short runs of straight pipe required upstream from pumps, flowmeters, and other critical components used in the process industries.

Inadequate lengths of upstream piping, valves, compressors, spiral welded pipe, expansions, reductions, and elbows alter the media’s tangential, radial, and axial velocity vectors. These alterations generate swirl, jetting, and velocity profile distortions.

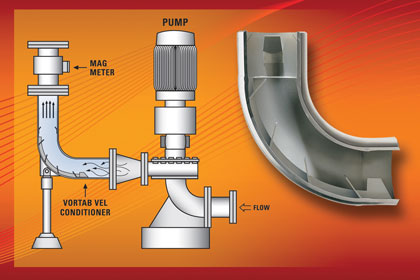

Wastewater treatment engineers who can’t find room for the recommended straight pipe run needed by electromagnetic flow meters in sewage lift stations will find the Vortab Elbow Flow Conditioner from the Vortab Company eliminates the problem by removing swirl and asymmetric velocity profiles caused by pumps placed too close to the meter.

To provide accurate and repeatable flow measurement, electromagnetic and other types of flow metering technologies require a specific amount of straight pipe run upstream and downstream from the installed location of the meter. The straight pipe runs create a swirl-free and symmetric velocity profile in the pipe that can be measured accurately over and over again.

When electromagnetic flow meters are placed too close to pumps in sewage lift stations, there can be measurement problems. Sewage lift stations are required to pump wastewater from one elevation to a higher level when gravity flow isn’t feasible for any number of reasons. Often there isn’t enough available plant real estate to support the straight pipe run required by electromagnetic and other flow metering technologies.

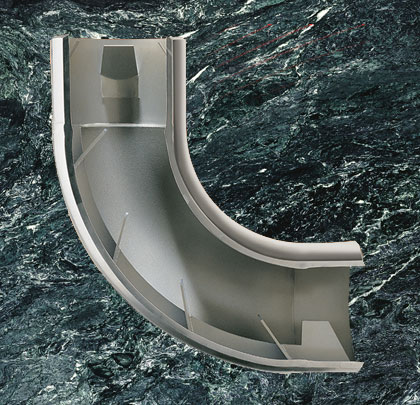

The Vortab Company’s elbow flow conditioner eliminates the flow meter upstream piping requirements by conditioning the flow stream into a flow regime, mimicking adequate straight run. In addition to conditioning the flow stream, the 90-degree angle tab-type Vortab Elbow Flow Conditioner eliminates the pipe cost and technician labor for the 5 to 10 upstream and 3 to 5 downstream pipe diameters required by mag meters.

The Vortab Elbow was developed using the same tab-type flow conditioning technology as the straight run Vortab Flow Conditioners, which have been laboratory proven and successfully installed in hundreds of plants worldwide.

To validate the Vortab Elbow’s unique design–ball valves, gate valves, out-of-plane and in-plane elbows and swirl generators were installed at the immediate inlet of the Vortab elbow and tested in state-of-the-art gas and liquid calibration facilities.

The Vortab Elbow Flow Conditioner isolates the flow irregularities and conditions the flow stream into a swirl-free and symmetrical velocity profile. Swirl reduction and velocity profile correction occur naturally in long lengths of straight pipe due to diffusion and turbulent mixing. Vortab’s anti-swirl and inclined vortex generating profile correction tabs, projecting from the inside pipe surface, generate vortices that accelerate these natural pipe effects to create a uniform, non-swirling, symmetrical flow profile in a much shorter section of pipe.

The simple, flexible designs of the Vortab Elbow, the Vortab Insertion Panel (VIP) and the Vortab Insert Sleeve, Short Run, Meter Run and Field Kit configurations provide a cost effective solution to crowded installations for flow meters and other critical process equipment. Vortab provides the most effective flow disturbance isolation, lowest pressure drop and least affected by fouling of any of the flow conditioners available.

Vortab flow conditioners can be made from carbon steel, 316L stainless steel or Hastelloy C-276. A variety of process connections are also available—ANSI flanges, male NPT threads, butt welded preps or retaining wafers. Delivery time for the Vortab flow conditioner is available in less than five weeks, depending on size. Custom configurations are also available from the factory.

Flow disturbances adversely affect differential pressure, turbine, vortex shedding, ultrasonic, and magnetic flowmeter technologies. Poor piping practices increase flowmeter error, often outside of the specified performance limits of the flowmeter manufacturer. Flow disturbances can induce cavitation and noise in pumps, control valves and other critical process components resulting in excessive wear and damage.

In today’s flow metering environment, accuracy, and repeatability are critical. The Vortab Elbow ensures accurate and repeatable measurement by eliminating flow distortions that degrade flowmeter performance. The simple, flexible designs of the Vortab Elbow and the VIP provide a cost effective solution to poor installations for flow meters, control valves, pumps, and other process equipment—as well as the most effective flow disturbance isolation, lowest pressure drop, and least affect by fouling of any of the conventional perforated plate, tube, or rotational vane type flow conditioners offered in the market today. ■

[divider]

For More Information

The Vortab Company is a global supplier committed to meeting the needs of its customers through innovative solutions to the most challenging requirements for optimizing flow meter accuracy and repeatability in gases or liquids. For more information, call 800.854.9959 or visit www.vortab.com.

MODERN PUMPING TODAY, August 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!