Depending on your application, high-capacity pleated cartridges can have many advantages:

- One 7 by 36 inch (177.8 by 914.4 millimeter) high-capacity pleated cartridge can replace as many as forty 2 1/2 by 10 inch (63.5 by 254 millimeter) string-wound cartridges.

- Disposal costs are lower because of the high dirt capacity. A high-surface-area cartridge may only have to be changed out two or three times a year compared to possible weekly change-outs when using standard cartridges.

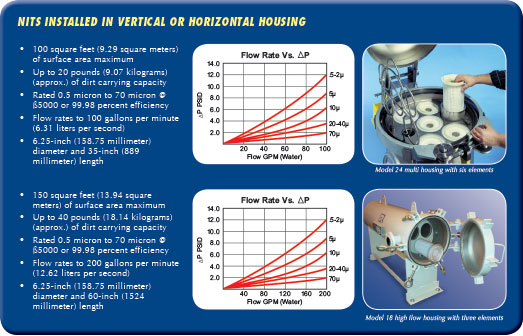

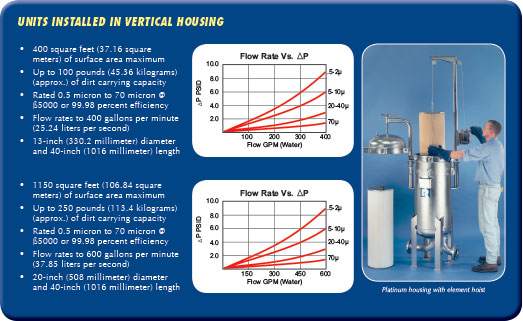

- Cartridges can be used in vertical or horizontal housings. If downtime cannot be tolerated, parallel filters sized to handle the total flow rate can be used.

- High capacity cartridges are made from several types of filter media and pore sizes in order to maximize dirt-holding capacity. Available filter media materials are; polyester, polypropylene, cellulose and fiber glass. This allows for a compatibility with a wide variety of fluids at various temperatures.

Absolute-rated filter cartridges offer maximum dirt holding capacity coupled with micron retention ratings to 0.5 at beta 5000 or 99.98 percent efficiency.

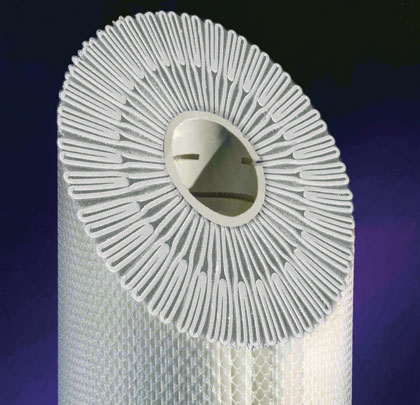

Elements are manufactured in a unique “Y” pleat arrangement that optimizes its physical size and maximizes effective surface area. A low fluid flux rate (gallons per minute per square feet of surface area) maximizes dirt containment. This means element life is extended and productivity is increased, resulting in fewer cartridge change-outs, less labor, and lower replacement costs.

This design uses only the highest quality materials and most advanced manufacturing processes. The end caps are heat sealed for high efficiency performance. The o-ring seal insures sealing and eliminates bypass.

THE IMPORTANCE OF BETA RATINGS

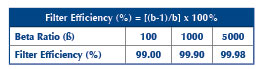

A filter with a Beta Rating of 5000 means that it has an efficiency rating of 99.98 percent at the specified micron rating. This means the contaminant reduction ratio is 5000 to 1.

In contrast, a 99 percent efficiency filter has a beta ratio of 100. A beta 100 filter will pass 1 in 100 particles at the given micron rating. Beta ratings are an indication of the filter performance throughout the life of the filter. Beta ratings are established during testing by averaging the performance values at intervals of 2PSID differential pressure until the filter is dirty. The range is typically from initial pressure drop to terminal pressure drop at 30 PSID.

The Beta Ratio (ß) at a given particle size can be correlated to the filter efficiency at that particle size according to the following formula:

Each filter element will have a different Beta Ratio for every specified particle size. The determination of a variety of Beta values for the same filter provides a filter efficiency profile commonly referred to as a Beta Curve. Beta Ratings allow the user to select the performance that the individual application requires.

CHANGING THE CHANGE-OUT

These new cartridge housings are designed to end the high cost of cartridge change-out. They are offered in single cartridge and multi-cartridge housings. Standard features include

- From 1 to 38 cartridges

- Multi-cartridge units are offered in the low profile design, for quick and easy cartridge removal

- Horizontal or vertical mount

- Housings available in carbon steel, 304 or 316 stainless steel and polypropylene

- Pressure ratings in 100, 125, and 150 psi

- ASME code stamp available on selected models

- Flanged or threaded connection sizes from 2-inch (50.8 millimeter) through 12-inch (304.8 millimeter)

- Covers are o-ring sealed and easy to remove

- Leg assembly (excludes CR8)

- Clean and dirty/gage port connections

- O-ring seals: Buna, Ethylene Propylene, Viton®, and Teflon® Encapsulated Viton®

The benefits are a decrease in cartridge use, reduced labor, inventory, worker exposure and disposal costs. A single cartridge holds as much as 20 pounds (9.07 kilograms) of contaminant with flows to 100 gallons per minute (6.31 liters per second). Because of the plug in design, the labor-intensive v-posts and spring seals associated with smaller cartridges are eliminated. The cartridges are easily removed, requiring no special tools. The large diameter 13 by 40 inches (330.2 by 1016 millimeters) and 20 by 40 inches (508 by 1016 millimeters) cartridge housing are equipped with a removal cable and hoist assembly.

Cartridges are designed to fit all standard housings, and multi-housings. Typical cartridge size specifications and flow rates are detailed in this article’s diagrams. For most users, high capacity cartridges unit will outperform standard wound or pleated cartridges and reduce maintenance time and cost.

_______________________________________________________________________

ABOUT THE AUTHOR

Dan Morosky is the vice president of sales and marketing of Rosedale Filtration Products. For more information, call 800.821.5373, email filters@rosedaleproducts.com, or visit www.rosedaleproducts.com.

_______________________________________________________________________

MODERN PUMPING TODAY, September 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!