Some of the most spectacular discoveries of what the universe is composed of—including antimatter and the Higgs boson —have been made by particle accelerators at CERN. The pumps that circulate gas mixtures through these particle detectors must be extremely reliable and keep the gases contamination-free. To meet these strict requirements, the particle collider relies on KNF as the world market leader in diaphragm pump technology.

WHAT IS THE UNIVERSE MADE OF?

The renowned research facility CERN is probing into the fundamental structure of the particles that make up everything around us. Located deep underground, partly in Switzerland, partly in France, multiple circular and linear particle colliders are used for experiments that have brought several groundbreaking achievements, like the discovery of the Higgs boson or the isolation of antimatter.

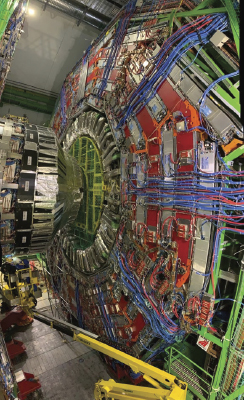

CERN’s research work uses some of the world’s largest and most complex scientific instruments. The largest particle collider at CERN, the Large Hadron Collider (LHC), is located 100 meters underground to cancel out environmental impacts such as radiation. Here, particles are accelerated to almost the speed of light and then collided with each another. Detectors record the phenomena occurring during these collisions.

PARTICLE ACCELERATOR REQUIRES DEMANDING GAS MIXTURE

When charged high-energy particles collide with gas, they leave a trail of ionization in their wake. These signals can be amplified using electric fields and then measured electronically to trace particle tracks with a high level of precision. The results of these experiments provide deeper insights into the structure of matter.

At CERN, around thirty gas systems are in use to supply the detectors in the LHC experiments with the right gas mixture. The mixture is a sensitive medium where the charge multiplication produces a signal that is recorded and analyzed. That is why a correct and stable gas mixture composition is key to the efficient and reliable operation of the particle collider experiments.

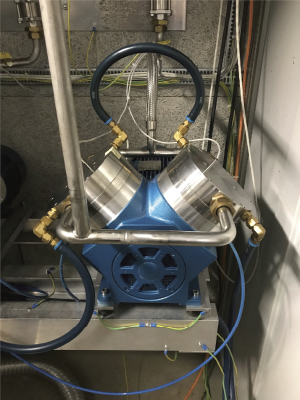

Gas mixtures for these particle detectors are composed of noble gases such as argon, xenon, helium, and other gases such as tetrafluoromethane, tetrafluoroethane, sulfur hexafluoride, isobutane, and carbon dioxide. KNF diaphragm pumps are deployed to circulate the gas mixtures and ensure they are free of contamination.

DRAWING FROM EXPERTISE AND EXPERIENCE

After working with KNF for decades, teams at the experiments highly value the company’s expertise and experience. When new diaphragm pumps were required to purify the specific gas mixtures and circulate them in one of CERN’s four particle detectors, the Compact Muon Solenoid (CMS), two KNF pumps were chosen, and a third installed as a backup.

Decades of successful collaboration with CERN enabled KNF to understand and deliver customized solutions for these highly specialized applications. Recently, the CERN Gas Team was proactively involved in the customization of the KNF process pumps N 0150 and N 1200.

COOPERATION LEADS TO LONGER SERVICE LIFE

Based on the CERN Gas Team’s observations, KNF was able to increase the service life of the diaphragms by modifying the design of the pumps. Evidence of CERN’s continuing confidence in KNF comes from an additional order for eighteen KNF pumps with a flow rate of approx. 170 l/min. These pumps were installed at the particle accelerators in 2022.

KNF serves customers in various industries, such as medical technology, mechanical engineering, process engineering and laboratory technology. Thanks to our modular system we can offer unmatched levels of flexibility to ensure that specific requirements of each market are met. For more information, visit www.knf.com.