The safety and reliability standards for equipment that provides potable drinking water are high, and for good reason. Any point in the water treatment and delivery process could be a potential point of contamination. However, the good news is that the market now has more options than ever. National Pump Company, a recognized specialist in the manufacture of vertical turbine pumps, is expanding its NSF 61-certified product catalog with a substantial range of new material options, giving customers more flexibility than ever before in meeting specific project requirements.

This latest update marks the most significant advancement to date. With the addition of nineteen materials, the total number of NSF-certified choices has increased from thirty-six to fifty-five across thirteen certified components. This expansion raises the number of potential component and material combinations to more than 199 million, giving engineers and end users an unmatched level of flexibility when specifying pumps.

MORE OPTIONS FOR MORE APPLICATIONS

These extensive NSF material additions include new mechanical seal options, expanded wear ring choices such as 17-4PH for bowls and impellers, and carbon steel alternatives for bowl components supporting both fabrication and machining from round stock. National Pump Company has also substantially broadened its supplier base for many of these options.

WHAT IS NSF INTERNATIONAL?

NSF International is an independent, non-governmental, non-profit public health and environmental organization that serves the public globally, by testing products for health and safety. The organization develops public health standard and certification programs that designed to protect our global resources and environments. The standards for drinking water systems have been specifically developed to protect our greatest resource, water.

GREATER CHOICE ACROSS THE ENTIRE SUPPLY CHAIN

More suppliers have been qualified for key components like coated column pipe, mechanical seals, tube assemblies, and marine bearings, ensuring greater availability, procurement flexibility, and responsiveness to customer preferences.

Enhanced supplier variety also applies to packing materials, valves, fittings, tubing (including PVC), and fastening methods such as rivet nuts and pop rivets for securing submersible screens. These changes allow customers expanded selection based on material performance, cost and availability considerations, while preserving full NSF 61 certification integrity.

MEET YOUR PERFORMANCE NEEDS

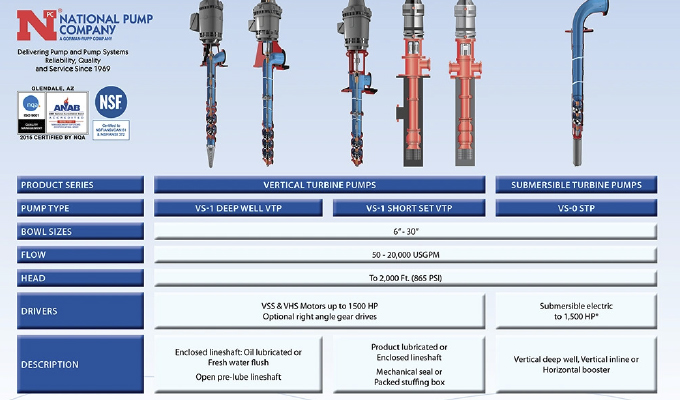

National Pump Company’s certified pumps include both vertical and submersible turbine pumps. The deep-set Vertical Turbine Pumps are available in configurations that include either oil-lubricated or fresh water flushed enclosed lineshaft or pre-lubricated open line shaft. The short-set vertical turbine pumps are available in either product lubricated or enclosed lineshaft configurations.

NPC has certified many optional materials to allow our customers the ability to choose the best materials for their specific application. Whether its standard materials, stainless steel or aluminum bronze, National Pump can meet your needs. Bearings options also include bronze, neoprene, marine or Vesconite. Wear rings are available in stainless steel or aluminum bronze. Seal options include mechanical seals in split or single cartridge configurations or expanded PTFE yarn packing. Standard coating is Tnemec N-140 Pota-Pox Plus to provide long-lasting protection of the steel components.

Expanding our NSF-certified material catalog allows us to provide customers with more choices and more ways to achieve their performance objectives. Every expansion reflects our commitment to engineering excellence, continuous improvement, and meeting the evolving needs of the markets we serve.

National Pump Company is a leading manufacturer of vertical lineshaft turbine, submersible, and booster pumps, serving a wide range of markets, including industrial, municipal, and API applications. Headquartered in Glendale, Arizona, at an ISO 9001:2015 certified facility, National Pump operates six strategically located build and service centers across the United States, ensuring responsive customer support and rapid product delivery. The company’s complete pump line is NSF certified, and standard products are available for quick shipment with off-the-shelf components to meet diverse customer needs. National Pump Company’s vision is to be a leading fluid pumping solutions provider in the global water and energy markets through collaboration, innovation and engineering excellence. For more information, visit www.nationalpumpcompany.com.