See Part 1 Here.

In the first half of this series, we explored how increasing use of above ground pump stations is transforming wastewater collection systems, a move that simplifies maintenance by making the equipment more accessible and eliminates the need for workers to enter dangerous, confined spaces, thus improving safety. Below, we’ll take a closer look at the history of above ground systems as well as delve into the technical reasons these advancements in lift station design have led to a track record of more economical costs, safer performance, and efficient operations for a variety of applications.

PUMP STATION PROGRESSION

A century ago, the original design of pump stations organized the placement of the pumps in a dry location. This led to the adoption of a “dry-well” or “dry-pit” arrangement, where the pumps were located in a separate chamber, adjacent to and isolated from, the wet well that collected the wastewater.

These pump stations were custom designed, constructed and assembled onsite, much like any traditional construction project. This process involved the contractor being responsible for procuring all necessary components to build the pump station at the location. Components such as pumps, valves, pipes, and control systems were sourced from specialized suppliers. This process was susceptible to delays due to supply chain issues and adverse weather conditions.

FACTORY BUILT AND TESTED PUMP STATIONS

The first major innovation in pump stations occurred in the late 1940s when Smith & Loveless introduced complete prefabricated pump stations. This packaged solution streamlined construction and operation, with the vendor assuming single-source responsibility and support throughout the product’s lifespan.

These prefabricated systems featured a steel structure, designed for continuous human occupancy, encompassing all the required components such as pumps, controls, valves, and piping. This integration significantly expedited the installation process for contractors. Additionally, factory-built and factory-tested solutions reduced project costs and timeframes by eliminating the need for designing and constructing subterranean spaces or basements. The pump station was shipped virtually complete and dropped into place and piped up.

SUBMERSIBLE LIFT STATIONS

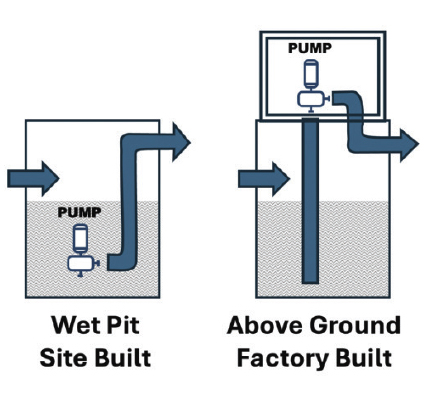

Later submersible wastewater pumps, initially developed in Europe, were introduced into the US in the 1960s and began achieving widespread adoption in the 1980s with the development and refinement of guide rail systems. Submersible lift stations employ sealed pumps that operate while fully submerged in the wet well. These pumps are periodically lifted to the surface for maintenance and reinstallation via guide rails and a hoist.

While submersible lift stations require only a single underground chamber to house the pumps, which minimizes excavation and construction costs, they still require a separate valve vault, usually placed a few feet away from the wet well. These sub-surface spaces are smaller and much shallower than an underground pump room chamber, but they are not always “designed for continuous human occupancy.”

This phrasing is a key aspect of determining whether entry into a given work area may be deemed a confined space per OSHA guidelines. These valve vaults can lessen the need for operators to have to access the wet well, the potential of hydrogen sulfide gasses and flooding create hazards that can classify them a confined space. Inside the wet well, the submersible pump components, including the motor and electrical connections, must be sealed to protect them from moisture penetration and corrosion.

Not only are the pumps constantly exposed to the raw sewage, but so too are operators when they perform inspections and maintenance. Paradoxically, while submerging pumps in wastewater increases the necessity for physical inspections, it simultaneously makes the inspection process more difficult and onerous. Handling equipment covered in raw sewage is not a pleasant or safe task!

The EPA advises that submersible pumps undergo inspections at least four times a year. This recommendation stems from the fact that sand, grit, and other abrasive and corrosive materials can wear down the pumps, creating gaps between the impeller and wear ring, significantly diminishing their performance.

ABOVE GROUND PACKAGED SYSTEMS

The third and final significant advancement in lift station design emerged when Smith & Loveless tackled the limitations associated with submersible pumps by pioneering the development of the above ground Wet Well Mounted Pump Station. This configuration strategically positioned all the mechanical equipment of the pump station outside and above the wet well, usually at ground level.

This innovation eliminates the need for a separate valve vault used in submersible lift stations, lessening excavation further while enhancing safety by eliminating the necessity of workers entering confined spaces.

Moreover, it overcomes the drawbacks of submersible pumps by situating the pumps in a dry environment. Positioning the pumps in a dry and safe location significantly increases their reliability and longevity and simplifies inspection and maintenance processes.

Pumps in state-of-the-art above ground lift stations operate reliably for more than twenty to thirty years, with basic maintenance. This durability stands in stark contrast to the typical lifespan of submersible pumps, which ranges from three to seven years.

Operations and maintenance are also radically streamlined. After opening the enclosure, a single operator can visually inspect pumps, valves, and other mechanical components in seconds and can access the impeller or mechanical seal in a few minutes, without the need to clean sewage off the equipment. And because of the vertical construction, there are no sewage spills when the pump is opened because the wastewater falls straight back into the volute and into the wet well.

MORE ECONOMICAL OPTIONS

Above ground packaged lift stations have proven to be more economical than submersible pump systems because of lower installation costs, reduced operation and maintenance expenses, and a longer system lifespan.

Installation Costs

Consider the full scope of installation expenses. Unlike submersibles, above ground pump stations are fully pre-assembled and rigorously tested as complete systems before shipment. This advantage significantly cuts down on the time and labor required for on-site piping, electrical work, and testing.

Furthermore, procurement expenses are notably lower with packaged systems, as they come equipped with many components that would otherwise have to be acquired separately. In contrast, submersible pump systems necessitate additional elements such as a guide rail assembly, pump lifting gantry, lifting chains or cables, suction pipes, power cables, control panel, and the wet well cover. Moreover, the installation of discharge piping and valves, not to mention a valve vault and its cover to encase them, further escalates the costs.

Operations and Maintenance Costs

The full life-cycle expenses of lift stations encompass time and materials for maintenance and repairs, energy efficiency, downtime impact, externally contracted services, and depreciation based on the anticipated lifespan of the equipment. Routine tasks like pulling a pump to change a seal or impeller can be completed in minutes by a single operator, without the use of multiple operators, outside contractors or pricey pump maintenance centers. This contributes significantly to lower parts and O&M costs when compared to submersibles.

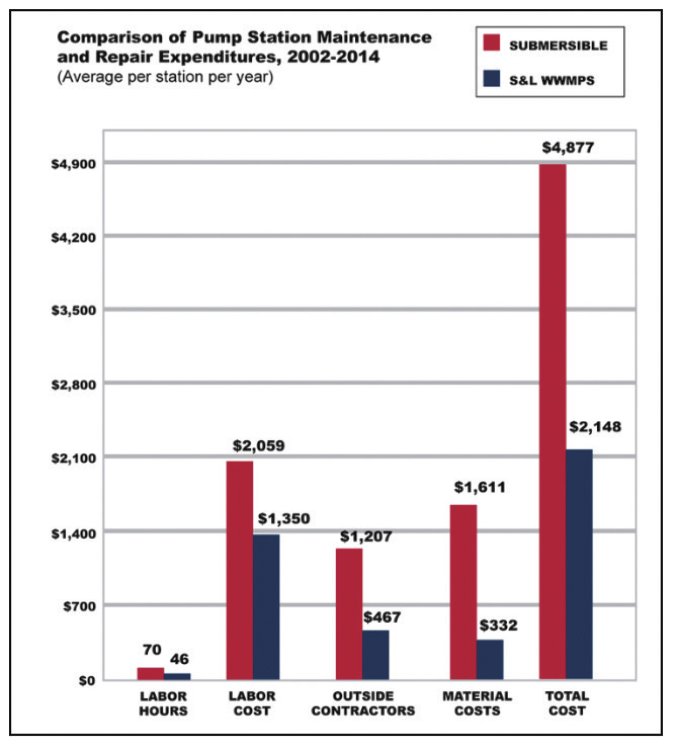

A published, comprehensive twelve-year side-by-side study by one municipal-county utility demonstrated the life-cycle cost advantages of above ground lift stations compared to their submersible pump counterparts. Utilizing asset management software, the study meticulously recorded all maintenance and repair expenses for fifty-three duplex pump stations within Wyandotte County’s (Kansas) wastewater collection system. This enabled a comprehensive analysis of the operational and maintenance costs between twenty-one submersible pump stations and thirty-two above ground packaged systems from Smith & Loveless, all functioning under similar conditions and applications.

The findings revealed that the above ground systems yielded nearly 56% in total cost savings. This translated to an average annual saving of over $2,700 per station, culminating in almost $400,000 in savings for the city during the span of the study. Perhaps the single most dramatic part of the study’s findings revealed that in the twelve-year period, not one pump of the thirty-two above ground pump stations required replacement, whereas forty pumps needed replacement in the county’s twenty-one submersible stations during the same time period.

A SENSIBLE CHOICE

Above ground lift stations are a sensible choice for many small and medium-sized pump station applications. These systems position the pump in a conveniently accessible and dry area to simplify design, prolong lifespan, and ease inspection and maintenance. By using a pre-assembled, factory-tested solution, above ground lift stations also guarantee straightforward, economical installation. Moreover, the single chamber design ensures a compact footprint, minimizing excavation costs, and the above ground stations remove the risks and inefficiencies associated with entering confined spaces for inspection and maintenance.

By improving the accessibility of equipment, significant safety challenges are eliminated, and costs are drastically reduced without compromising the integrity of the pump system. Increased reliability, efficiency, and longevity provided by above ground systems guarantee improved performance and operator safety, and reduced financial spending.

As a pioneer of pumping systems for seventy-five years, Smith & Loveless has spearheaded the innovation for above ground pump systems, with continuing advancements in the design and production of these stations. Designed with a focus on robustness and a keen awareness of the most pressing industry challenges, above ground lift stations protect both operators and employers, and offer lifespans that are significantly longer than submersible pumps. It is, therefore, no surprise that operators facing workforce challenges, flushables, and economic pressures are increasingly turning to above ground pump stations over conventional submersible pumps to meet current and future demands. For more information, visit www.smithandloveless.com.