Whether it’s at product launches, factory tours, or trade shows, the staff at MPT is afforded an up-close look at the newest offerings for our industry, and each December, we look back on the year that was and present our choices for the Top Products spanning the industrial pump and rotary equipment markets.

In the pages that follow, MPT shares its selections for the products that speak to the industry’s needs for efficiency, reliability, and innovation. Each of our Top Products was chosen through submissions from our staff, advertisers, and readers like you. The products range from large multinationals you’re likely familiar with to smaller, regional suppliers worthy of your attention. Regardless of their size or reputation, they all offer value you can take into the new year.

CONTINENTAL ULTRA PUMP: CP Progressive Cavity Pump

Discover the power of precision and reliability with Continental Progressive Cavity Pumps. Continental pumps are engineered to handle a wide range of fluids including, but not limited to, abrasives and slurries to sewage and industrial waste. The Continental CP Model is designed for low flow and viscous applications. The simple design provides a compact pump that is light in weight with extended pump life and minimal routine maintenance. It’s a low-cost pump with specific construction materials that are based off application requirements and many drive options making this model a versatile solution. With customizable options and proven performance, Continental offers the perfect solution for your specific application. For more information, visit www.continentalultapump.com.

NETZSCH: Tornado T1 Generation F Rotary Lobe Pump

The Tornado T1 Generation F pump can handle a wide range of viscosities, solids, temperature, abrasion, and corrosive/acidic process fluids, and environments. The Tornado T1 Generation F pump is extremely versatile for just about any orientation and installation. Its robust design offers longevity, operational flexibility, and dry-run capabilities. It allows the pump to operate and handle many upset process conditions without causing harm to the pump. The pumps are available up to over 4,000 gallons per minute and up to 145 psi. This new Generation F series is the new, improved T1 design that offers up to 25 percent more efficiency. For more information, visit www.netzsch.com.

VAUGHAN COMPANY: Rotomix

Hydraulic mixing is a dirty job that requires a durable pump to keep things flowing smoothly. The Vaughan Rotamix system is the world’s most cost-effective and durable means of mechanical hydraulic mixing for sludge tanks, digesters and other high-volume applications. Cutting-edge and American-made, the Vaughan Rotamix pairs the original Vaughan Chopper Pump with a set of high-velocity nozzles to mix the tank, handling any tough solids. For federally funded projects, Vaughan’s pumps and pumping equipment meet all requirements to receive federal aid under the Build America, Buy America (BABA) act. For more information, visit www.chopperpumps.com.

MASS-VAC, INC.: MV Multi-Trap Vacuum Inlet Trap

The MV Multi-Trap Vacuum Inlet Trap combines several trapping methods and multiple stages to condense, absorb, and neutralize process byproducts that generate particulates, volatiles, organic solvents, and acids. Ideally suited for silicon solar cell processing equipment, the trap’s first stage is a 200 square inch baffle shield surrounded by 3/8 inch I.D. cooling coils for condensing volatile solvents and chemicals on a large cooled surface. Featuring user-selectable filter elements to address specific processes, the MV Multi-Trap Vacuum Inlet Trap is capable of up to 2,500 cubic inches of solids accumulation and is offered with a solid stainless steel knock-down stage instead of a water cooled baffle shield. For more information, visit www.massvac.com.

RUSSELECTRIC: ATS Remote Annunciator

The remote annunciator is designed to be configured by the customer. It allows monitoring of the position and status of up to eight Russelectric ATS types RTSCD and RPTCS, as well as viewing power data for each ATS and accessing current alarms and logged historical alarms. Users can initiate load tests and set timers remotely using the RS-422/485 Protocol to ATS. In addition, there is the ability to configure email alerts for alarms. An Ethernet connection is available for exchanging data via the OPC UA protocol to another SCADA or building management system. For more information, visit www.russelectric.com.

ATLAS COPCO: LRP 700-1000 VSD Vacuum Pump

The next big step in liquid ring technology, the LRP 700-1000 VSD series is perfectly suited to wet, humid, and dirty applications with high temperatures and extreme vapor loads. Atlas Copco’s liquid ring vacuum pumps are designed for energy and water efficiency. In addition to the high, stable vacuum performance, the liquid ring pumps are energy-efficient and ensure low operating and maintenance costs. Equipped with two variable speed drives (VSD: Variable Speed Drive Technology) the vacuum system saves energy and water: The first of the VSD twins maintains the required vacuum level by precisely controlling the operating speed of the pump, which ultimately reduces power consumption. For more information, visit www.atlascopco.com.

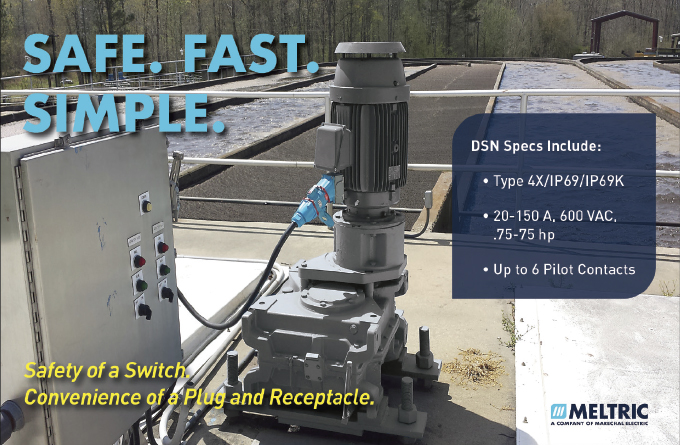

MELTRIC: DSN Series of Switch-Rated Devices

In the world of industrial electrical plugs and receptacles, MELTRIC DSN Series of plugs and receptacles redefine standards for electrical safety, efficiency, and innovation. Crafted with user safety and operability in mind, MELTRIC Switch-Rated devices are the go-to solution for eliminating downtime and safely conducting operations in varied pumping industries. MELTRIC plugs and receptacles simplify the complex task of motor and pump changeouts. What once took hours can now be accomplished in a mere fifteen minutes. Intuitive and revolutionary Push Button Disconnection made possible by DECONTACTOR technology ensures a swift and secure disconnection with proprietary Spring Loaded, Silver-Nickel Butt Style Contacts. For more information, visit www.meltric.com.

HYDRO-THERMAL: Non-Obstructing Heaters

Hydro-Thermal Non-Obstructing Heaters (NOH) are emerging as a superior alternative to traditional heat exchangers for sludge heating in anaerobic digestion. By maintaining optimal digester temperatures, these heaters increase biogas production, shorten detention times, and improve process efficiency, contributing to cost savings and sustainability. As industries prioritize efficient resource utilization and environmental responsibility, innovation and progress in wastewater treatment are paramount. Precise temperature control isn’t just about microorganism survival; it’s about maximizing their performance. It’s about converting waste into valuable resources like biogas, reducing the environmental impact of waste disposal, and contributing to a more sustainable future. For more information, visit www.hydro-thermal.com.