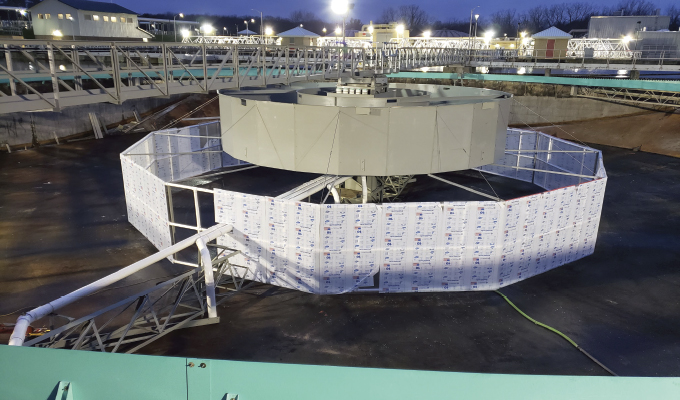

Every wastewater treatment facility eventually faces the challenge of aging and deteriorating equipment, affecting operational efficiency. Drives struggle to keep up their power, skimmers deteriorate and break, and corrosion wears away at crucial components. Not only do these factors demand additional maintenance and labor from employees, but also pose a threat of critical failure. To avoid a complete shutdown, plant managers may turn to new equipment purchases. However, replacing the old with the new isn’t always the best decision.

MORE THAN ONE SOLUTION

While purchasing new equipment is often an obvious solution to increasing power, identifying repair and retrofit services offers distinct, cost-effective advantages over new capital expenses. A common misconception about repair and retrofit services is that this option is only reserved for minor, more contained maintenance concerns. However, repair and retrofit services can be applied to equipment across an entire project, restoring integrated systems to their maximum efficiency and, in some cases, even better than their original condition.

Repair and retrofit services can offer a wide variety of solutions, but why is this path becoming a popular option over a new equipment purchase?

PRICE ALWAYS MATTERS

In the initial construction of wastewater treatment facilities, several factors are considered when purchasing original equipment. Life-cycle, replacement, and historical costs are considered carefully when planning a construction budget. However, equipment corrosion and, ultimately, machine failure are challenging to plan for. Numerous external variables can skew the expected equipment lifecycle and the efficiency of components in a wastewater treatment facility, throwing budgets out of whack and sticking decision-makers in an undesirable financial situation.

In the right applications, repair and retrofit services are budget-friendly options to help restore underperforming or deteriorating equipment to excellent condition, preventing the chance of critical equipment failure in the long run. Repair and retrofit service providers can also access equipment conditions across entire integrated systems, identifying underlying potential risks that pose a future threat to operations efficiency. The short-term cost to long-term benefit ratio of repair and retrofit services cannot be understated; extending the life of equipment gives facilities more time to accrue funds and restructure budgets for new equipment purchases and future growth.

SEAMLESS INTEGRATION

A wastewater treatment facility can consist of equipment from several different manufacturers. When initially constructed, careful consideration is given to ensuring that the interplay and interdependence of this equipment are at their most harmonious. However, replacing any one of these equipment pieces can throw off this ecosystem. New advancements in technology are constantly being made, and with this comes the challenge of compatibility. Now, the purchase of new equipment must hinge on budgetary restrictions and the availability of compatible equipment.

Repair and retrofit services help plant operators bypass the problem of finding compatible equipment. In almost every scenario, repair and retrofit service providers can modify and restructure the existing equipment to increase its resilience, power, and efficiency while maintaining its already established role in operation. Many service providers are well-versed in specs and maintenance across all major equipment manufacturers, allowing them to find solutions quickly. Removing the concern of compatibility from the equation makes solving issues with damaged equipment much less invasive and disruptive to project flow.

EMPLOYEE LABOR AND TRAINING

While new equipment can be exciting, it can also be a pain point for employees. With any new equipment installation comes different maintenance protocols, lengthy training on features and specs, and overall comfortability with the latest equipment. While equipment manufacturers provide the necessary tools for proper integration and training, the process of learning new equipment can sometimes be a drawn-out experience that impacts the efficiency of both employees and the operation.

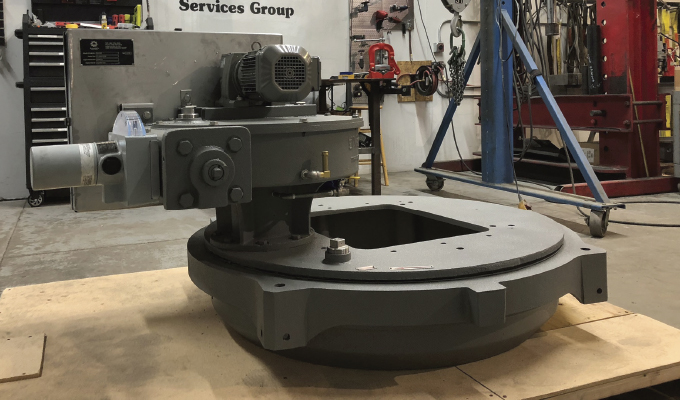

With repair and retrofit services, there is rarely an interruption in protocols or training. In many cases, service providers will simply take a piece of equipment that’s corroded or damaged and add anti-corrosion coatings, improve connection points, and reinforce with appropriate materials. Because the vital structure and functionality is left virtually untouched, employees spend minimal time learning how to properly use the repaired equipment. For larger repair and retrofit projects like a clarifier drive, most repair and retrofit service providers will also provide a monitoring panel. Some key features include a torque display and torque alarms for real-time data, running lights for easy monitoring of equipment, and a control knob for fine-tuning of clarifier speed. An integrated control panel can make the already minimal learning process even easier.

Some learning is required, whether purchasing new equipment or performing a repair and retrofit service. However, repair and retrofit services are the least invasive and rarely interrupt the normalcy of maintenance and monitoring tasks.

CHOOSING THE RIGHT PROVIDER

Building a long-lasting and trusting partnership with a repair and retrofit service provider is critical, just as it is with building a relationship with a supplier. Many of the same key qualities of equipment suppliers apply to repair and retrofit service providers: response time, honesty, adaptability, etc. However, one key quality of a repair and retrofit service provider stands above the rest: speed and efficiency.

Project turnaround time is the number one factor that decision-makers should consider when choosing a service provider, especially for emergency repair situations. A valuable repair and retrofit service provider should be able to make almost immediate site visits for evaluation and consulting, be composed of a team of veteran engineers, and have minimal installation time.

A relationship with a repair and retrofit service provider is much more involved than a supplier manufacturer’s. These teams aren’t just experts in one piece of equipment – they are prepared to perform a comprehensive deep dive into an entire facility and learn projects to provide the best solution. However, once this relationship is built, repair and retrofit service providers are an incredibly valuable asset. As previously mentioned, these partners can respond to immediate concerns and evaluate and identify potential problems before they cause emergency action. A strong partnership with a repair and retrofit service provider can significantly impact the long-term health of the facility.

Ultimately, every facility and project has unique needs, and there’s never an easy answer for finding solutions to problems. But, when it comes time to add more life to motors and drives or give your equipment extra life, repair and retrofit services might be the best answer.

Sentry Equipment is a global provider of sampling and process improvement technologies, combining proven abilities in engineering and manufacturing to help customers maximize their process efficiencies in a variety of markets and applications worldwide. With a process monitoring and service team dedicated to supporting operations large and small with highly skilled technical services and products, Sentry Equipment is peerless. What we do with engineering, we do with ourselves. We make things better together. For more information, visit www.sentry-equip.com.