Since the beginning of time, people have had the need to treat the water they consume, and use for cooking, bathing and washing their homes and cooking utensils. They have also needed to find ways to properly treat and dispose of the water that has been fouled through the course of its use—in latter centuries most commonly during industrial production activities. This need helped the water/wastewater-treatment industry grow to billions in revenue in the United States, and to an annual rate of growth anywhere between 3.0 and 4.5 percent.

When people hear the phrase “water treatment,” however, the first thought that comes to mind is taking water that will be used in domestic settings and removing any impurities, in the process making it safe to drink, cook with, bathe in and wash clothes with; in other words, “municipal” water treatment. But from a broader perspective, the term water treatment can have a number of completely different meanings.

In industrial applications, for instance, water can be taken from a nearby river and used for boiler or cooling-tower makeups. In the oilfield, water that is used or produced during the drilling and recovery process can be treated and sold to farmers for use in field-irrigation activities. In other words, there’s a whole lot of water being treated at all times, and not just so a loving parent can whip up a pitcher of lemonade for the kids.

This article will illustrate how an integrated wastewater treatment system, with many different types of equipment working hand-in-hand—specifically metering and peristaltic (hose) pumps, and polymer makedown systems—can be used in a straight-line treatment process. This will deliver the most cost-effective and efficient way to treat industrial wastewater, all while making it safe for disposal or reuse in any number of additional activities.

THE CHALLENGE

Most of the water used or produced in industrial applications contains some level of solid particles. It goes without saying that these particles should not be consumed, but particle-laden water also can’t be used, for example, in a boiler that provides steam to a turbine during power generation, lest the turbine become fouled and damaged.

Recognizing the presence of particulates in water and successfully removing them, however, are two different things. Some of the particles—which can be anything from bacteria and plant material to dirt or minuscule pieces of crushed stone—are so small that their response to gravity is very low. In other words, they don’t fall through water at a consistent rate because their mass is so small and not impacted by gravity. This means that it may take many hours, days or even weeks for the particles to settle as little as a foot. This is an unacceptable, and unpredictable, settling rate for a water or wastewater treatment system, so the particles need some help in settling or clumping.

To speed along the settling or clumping process, the water treatment facility must turn to the introduction of a coagulant or flocculant that helps the tiny particles clump together in a mass that is called a “floc,” which is easier to remove. Two of the more popular types of coagulants/flocculants that are used in water/wastewater treatment are:

- Alum: A more economical way to say “hydrated potassium aluminum sulfate,” alum has been used since Roman times to aid in the purification of drinking and industrial-process water. Alum coaxes negatively charged colloidal particles to clump together so they will be able to be more easily removed from settling basins.

- Ferric chloride: Another name for Iron (III) chloride, ferric chloride undergoes hydrolysis when dissolved in water, which gives it the ability to sufficiently form suspended solid particles into flocs.

While quite effective in creating flocs, the flocs that are formed by alum and ferric chloride are held together rather loosely, which means that they can break apart if agitated as they settle in the clarifier or settling basin. Eliminating this break-up potential requires the introduction of a polymer solution that helps form more efficient flocs. The polymer takes the neutralized solid particle clumps and binds them together more tightly.

Removing the sludge from the water requires a pump that can run dry and won’t be bothered by abrasive materials. In other words, a pump that has the capability to take whatever flows into it—no matter its makeup—and deliver it out the discharge side in that same form.

THE SOLUTION

Industrial water or wastewater treatment, then, is a three- stage process that must work hand-in-hand: initial floc formation with alum and ferric chloride, clump-strengthening with polymer, and removal and disposal of the sludge. Not all manufacturers of wastewater-treatment equipment are able to offer full lines of pumping and polymer- blending technology for the required water- treatment applications.

However, Neptune®, a brand of PSG®, a Dover company, does feature full lines of pumping and polymer-blending technology for industrial water or wastewater-treatment applications. This allows the water-treatment facility access to a “One Company. One Source.” solution that covers its needs from start to finish. Specific water-treatment technology from Neptune includes:

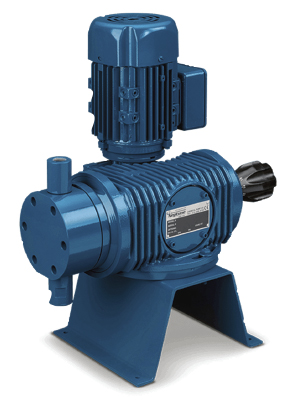

Neptune MP7000 Series Mechanical Metering Pumps

Ideal for dosing alum and ferric chloride, these mechanically actuated pumps eliminate the use of contour plates on the liquid side of the diaphragm, resulting in a simple, straight-through valve and head design that allows improved flow characteristics.

They have been designed to handle clear liquids with viscosities ranging from water-like to 2,500 cPs, making them ideal for use in industrial water and wastewater treatment applications. The capacity of the MP7000 and MP7100 Series pumps is manually adjustable via micrometer dial while the pump is running. This allows the pump to produce flow rates ranging from 2 to 300 gallons per hour at head pressures up to 235 psi (16 bar). The pump’s liquid ends are constructed of PVC, 316 stainless steel or Kynar. Washdown-duty and explosionproof motors, as well as variable frequency drive options, are also available. The pumps are also self-priming.

Neptune Polymaster Polymer Activation and Blending System

The Neptune Polymaster is a simple, automatic and economical solution for effectively diluting, mixing and thoroughly activating emulsion, dispersion and solution polymers, including new-high-molecular-weight products. With the patented, motorized Gatlin Mixer and Distribution Head, Polymaster provides better mixing capabilities and a higher degree of activation compared to similar machines.

By hydraulically segmenting the polymer into ultra-thin film platelets, the polymer surface area exposed to the dilution water is maximized without affecting the degree of activation. Offering manual stroke length control, automatic 4-20 mA speed control and models available for up to 50 gallons per minute dilute solution at concentrations from 0.1 to 2.0 percent, Polymaster provides a dynamic solution for polymer activation and blending without any blades to damage the fragile polymer chains. With a compact, lightweight design, accessible front panel components and automatic shutdown and alarm prompted by the loss of dilution water, the Polymaster is designed for easy installation, operation and maintenance.

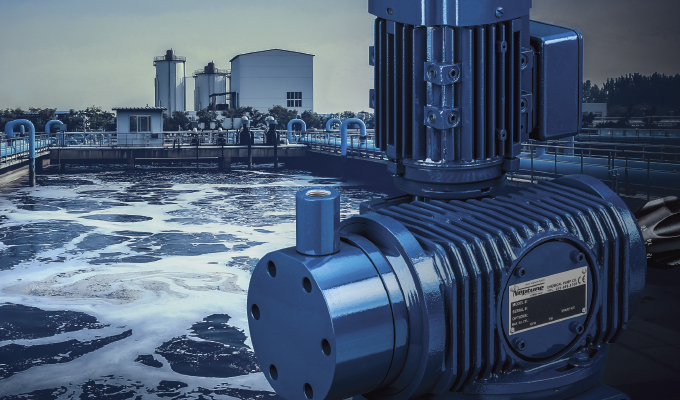

Abaque Series Peristaltic (Hose) Pumps

Featuring a design that ensures that “whatever goes into the pump comes out of the pump,” Abaque pumps can handle solid particles up to 0.59 inches and soft particles as large as 0.98 inches, making them a top choice for sludge removal. They feature a seal-free design that eliminates leaks, which enables them to handle the wastewater industry’s toughest pumping applications, from abrasive and aggressive fluids to shear-sensitive and viscous materials. The pumps, which can run in either forward or reverse, are self-priming, dry-running and offer suction-lift capabilities to 30 feet, as well as the ability to run dry continuously without adversely affecting the pump’s performance. Ductile-iron and steel construction lets the pump produce discharge pressures as high as 217 psi (15 bar). The Abaque’s pump hoses are available in four materials of construction: natural rubber, EPDM, Buna N, and Hypalon.

CONCLUSION

A wide variety of industries use untold millions of gallons of water and produce untold millions of gallons of wastewater each and every day. Properly handling and disposing (or reusing) this wastewater requires a number of stages that must work together seamlessly, from alum and ferric chloride introduction, to polymer injection, to sludge removal. Each stage requires a different type of technology, which can often have the wastewater-plant operator moving in many different directions to identify a solution. Neptune offers a one-stop shop for industrial wastewater treatment, with a ready supply of metering pumps, polymer makedown systems and peristaltic pumps, all of which have been designed to work in hand- in-hand to create the most efficient and cost-effective industrial wastewater-treatment process.

FOR MORE INFORMATION

Siemens Digital Industries Software, a business unit of Siemens Digital Industries, is a leading global provider of software solutions to drive the digital transformation of industry, creating new opportunities for manufacturers to realize innovation. With headquarters in Plano, Texas, and over 140,000 customers worldwide, we work with companies of all sizes to transform the way ideas come to life, the way products are realized, and the way products and assets in operation are used and understood. For more information, visit www.sw.siemens.com.

MODERN PUMPING TODAY, June 2024

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!