Ensuring optimal temperatures is paramount for many industries, from healthcare to food processing. It can help companies safeguard employees and comply with regulations. A wireless temperature monitoring system offers an efficient and advanced solution.

KEY TEMPERATURE REGULATIONS ACROSS INDUSTRIES

Healthcare

Medications require storage between 59 to 77 degrees Fahrenheit (15 to 25 degrees Celsius). Blood bank storage requires temperatures from 95 to 122 degrees Fahrenheit (35 to 50 degrees Celsius).

Production Facilities and Computer Rooms

Specific areas must be maintained at much cooler temperatures than other parts of a facility to prevent equipment overheating that can damage computer components. ASHRAE recommends 64.4 to 80.6 degrees Fahrenheit (18 to 27 degrees Celsius) or A1 to A4 class hardware.

Food Processing

The USDA demands precise temperatures for stored foods. Dry grains should be stored at temperatures of 50 degrees Fahrenheit (10 degrees Celsius), refrigerated foods between 32 to 40 degrees Fahrenheit (0 to 4 degrees Celsius) and frozen foods at 0 degrees Fahrenheit (-17 degrees Celsius)

THE INADEQUACY OF MANUAL TEMPERATURE TRACKING

Manual temperature tracking is not only time-intensive but also error-prone. Temperature discrepancies can result in product corruption or halted operations since they can take hours to identify.

And what happens if temperatures rise in a computer room or storage area after hours? Most likely, spoilage or equipment failures that result in thousands of dollars in lost revenue.

The answer? A wireless temperature monitoring system.

HOW WIRELESS TEMPERATURE MONITORING SYSTEMS EXCEL

These systems, compared to outdated manual methods, harness advanced technology to streamline and automate temperature management. They can be utilized in facilities or within transportation fleets holding chilled products.

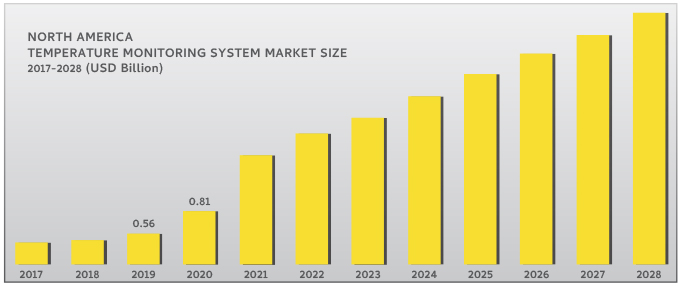

Their rising popularity is evident in the growth from $2.19 billion in 2021 to a projected $4.71 billion by 2028, per Fortune Business Insights.

WHY OPT FOR WIRELESS TEMPERATURE MONITORING SYSTEMS?

More companies are installing wireless temperature monitoring systems based on the many benefits derived from it. Here are five:

Real-time Monitoring

Facilitates 24/7 real-time tracking, regulation, and control, even remotely via smart devices. A remote temperature monitoring system streamlines operations by enabling operators to easily track, control, and regulate temperatures in different environments simultaneously in real-time on a 24/7 basis without even entering the facility.

Information is accessible from a control room or in the field from smart devices so personnel don’t have to be in the immediate vicinity to gather readings.

Configurable Alerts

Instant alerts for specific temperature thresholds to preemptively address changes. Systems are configurable to send an alarm when temperatures reach a specific threshold.

Assigned personnel automatically receive alerts to take immediate action. Even a slight change in temperature will prompt an alert that gives enough time to make corrections or identify any equipment failures that may contribute to varying temperature levels.

Customizable Thresholds

Adapt temperature settings based on distinct operational needs. Users can set minimum and maximum thresholds for specific areas to customize operations. Some operations can handle larger temperature deviations while others can only tolerate minor changes so having the ability to customize specific thresholds for each application is important.

Data Logging

Oversee temperatures over durations for compliance and quality control. Analyze data for system reliability. Companies can monitor temperatures over time for compliance reporting or to gain a better understanding of what temperatures products have experienced over time to make informed decisions about quality control. Analytic reports also provide information on spikes, anomalies, and failures to evaluate the reliability of a refrigerator, HVAC, or other system that serves to cool the environment.

Convenient Installation

Compared to hard-wired systems, wireless systems are easier to install and more adaptable. A wireless temperature monitoring system simplifies operations over hard-wired installations as it eliminates the need run cables from sensors and the remote monitoring system. In addition, cables may present tripping hazards in a facility or require building modifications to run them through walls, floors, and ceilings. Hardwired systems also may not be feasible in monitoring different assets in large-scale environments such as greenhouses. Installation of wireless systems also may be cheaper and faster.

WIRELESS TEMPERATURE MONITORING PRODUCTS

The Sensaphone WSG30 is an efficient wireless system, especially tailored for monitoring refrigerators and freezers housing valuable items like vaccines. It can support up to thirty wireless sensors and alert up to thirty individuals about any irregularities.

Also, the Sentinel PRO Monitoring System with Cellular Modem is a cloud-integrated option ideal for locations without a conventional internet connection. It offers cloud storage for sensor readings, ensuring data protection, and infinite storage capacity.

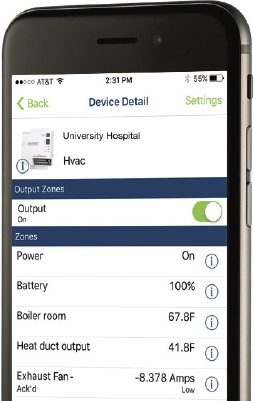

The cloud-based Sentinel allows you to monitor remote facilities and environments. Users can check the status of critical equipment with the same degree of certainty as if you were at the device.

Sentinel’s mobile app offers immediate access to your readings. Monitor your environment from anywhere using a simple, powerful web-based interface and mobile app. If there’s a disruption, you’ll be the first to know. Alerts can be sent straight to your mobile device—keeping you updated and giving you peace of mind wherever you are.

FOR MORE INFORMATION

Rob Fusco is director of business development with Sensaphone, a developer and manufacturer of remote monitoring and alerting systems. He can be reached at rfusco@sensaphone.com or 877.373.2700. For more information, visit www.sensaphone.com.

MODERN PUMPING TODAY, February 2024

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!