To mark the new year, Wanner International has announced that it can reduce the total energy usage by up to a half for some industries that rely heavily on pumps for their processes. The company is focusing on the importance of reducing energy consumption in the wake of COP26, and wants to highlight that it is playing its part in making a more sustainable future a reality.

Wanner provides pumps for a range of industries across the globe, from oil and gas, through to food production, chemical, and pharmaceutical production. Of course, it can’t on its own solve the carbon crisis, but what it is doing is examining every pump it manufactures, helping customers reduce energy usage by careful placement of Hydra-Cell® pumps, and squeezing carbon out of the system.

THE RIGHT PUMP FOR ENERGY EFFICIENCY

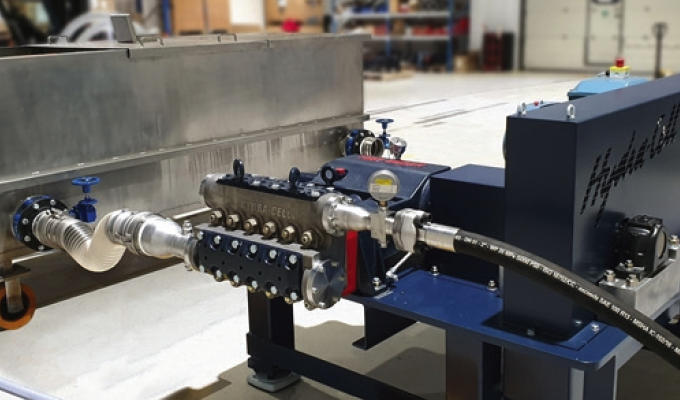

Choosing the right pump technology can have an effect on energy usage. The Hydra-Cell pump’s true positive displacement action and minimal internal losses achieve high efficiencies from pump shaft to hydraulic power; this combined with the wide range of flow rate controllability ensures optimum energy usage. Alternative pump technologies with inherent internal losses, which get larger as internal parts wear, start to become lower in efficiency as the discharge pressure goes above 10 bar and only gets worse with increasing pressure.

Some of Wanner’s Hydra-Cell pumps have been reliably operating in the field for a quarter of a century plus, which again frees resources that can be devoted into improving sustainability. Considering that some industries in which Wanner operates, such as oil and gas, are shifting heavily into renewables, the flexibility of the Hydra-Cell pump to handle many different liquids coupled with its high energy efficiency and reliability has a large role to play in reducing the carbon footprint.

Switch on your TV and you will see climate disasters around the world taking lives, homes, livelihoods, and destroying ecosystems. From soaring temperatures causing wildfires that ravaged Greece and Australia to unprecedented levels of rainfall that led to severe flooding in Germany and South Asia—around the world, everyone is being affected by climate change.

And everyone needs to be part of the solution. We are dedicated to enabling our customers to save energy, to save resources and we hope that with our leadership, they will follow this example across the whole of their supply chains.

LOW ENERGY CONSUMPTION FOR LOW CARBON FOOTPRINT

Globally pumps in the industrial sector represent approximately 25 percent of the energy usage, and in pump intensive industries as much as 50 percent. Choosing the right pump technology to optimize energy usage is critical. The environmental issue is now very important to all; optimizing energy usage has never been as important.

Compared to other technologies, the Hydra-Cell pumps true positive displacement pumping action and minimal internal losses achieve high efficiencies as measured from pump shaft to hydraulic output power. This combined with the wide range of flow rate controllability ensures optimum energy usage.

CONSTANT FLOW RATE INDEPENDENT OF DISCHARGE PRESSURE

The Hydra-Cell pumps minimal internal losses ensure a consistent flow rate. With no dynamic seals or packing these internal losses stay minimal during use, unlike pumps with internal dynamic seals. This is especially important when pumping liquids with suspended micron size solids.

Many industrial processes require a consistent and controllable flow rate to ensure the quality of the product produced and to optimize cost of production, especially with expensive chemicals. The steady state accuracy of the chosen pump must be very good and be consistent from day 1 to day 100.

FOR MORE INFORMATION

Paul Davis is Wanner International’s managing director. Wanner International prides itself in supporting customers, personally. With many years of pump and application experience, there is extensive knowledge available in the Wanner technical pump engineers and support network here to help customers at the end of the phone, no matter where they are in the world. For more information, visit www.hydra-cell.co.uk.

MODERN PUMPING TODAY, March 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!