By Heinz Woldering, Lewa GmbH

Digitalization means growing opportunities for augmenting reality virtually. This is becoming particularly evident from looking at Industry 4.0 trends, which are opening up new options in the field of human/machine interfacing. As a specialist in pump and metering systems, Lewa GmbH has come up with two independent solutions to counteract problems that are common in everyday applications. The company based in Leonberg, Germany, has developed an app that presents a virtual, freely scalable ecoflow process diaphragm pump on an iPad and allows malfunctions to be simulated.

This makes it unnecessary to provide a demo model at trade shows, for example, and technicians at the customer’s facility can be trained more effectively. And augmented reality smart glasses have been available from Lewa for remote maintenance and initial diagnostics of malfunctions in operation since 2018. With the smart glasses, a connection to a service technician can be established to support the on-site employee with their repair and maintenance work.

Every day, advancements in the digital world are making new opportunities possible in both industry and daily life. Augmented reality, the concept of superimposing virtual images onto the real world, is an important cornerstone of the process. Especially in pump technology, where units often weigh several tons and have huge dimensions, and where a high degree of expertise is required for operating and maintaining the machines, technological options for making handling and demonstration easier are in demand.

Until now, for example, demo exhibits with plexiglass heads and pipeline models had to be designed for trade shows to explain how pumps work or to simulate malfunctions. This took lots of time and effort. This is why Lewa has developed an innovative app for training and demonstration purposes in collaboration with a digital agency. Lewa also offers a solution from augmented reality to improve servicing for the users of complex units: “Smart Glasses” allow service technicians to support on-site employees remotely during repair or maintenance work.

GROUND PLANE DETECTION EMBEDS A VIRTUAL PUMP MODEL IN ANY ENVIRONMENT

Lewa first developed an application with the goal of making it possible to present the interior of a pump in a physical exhibit. The application was originally intended for trade show presentations. In the past, we exhibited pump models with a plexiglass head to make it possible to view the inner working of the pump. But since not all of the interior components could be viewed and potential malfunctions could only be simulated to a limited extent, we collaborated with a digital agency in Munich to develop a suitable application for this purpose. The first version was released in 2018. It was capable of taking an ecoflow pump model on an iPad screen and superimposing a virtual interior view over the pump, providing an in-depth look into the processes and functional principles.

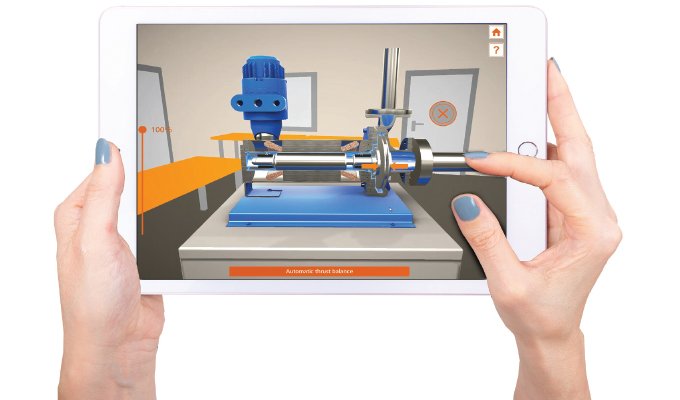

After numerous inquiries from customers, Lewa decided to embed this application into an app that could present a visualization without a physical model. Using ground plane detection, a method of placing digital content on horizontal surfaces such as floors or tabletops, the “orange showroom” app was launched in April 2019. The app makes it possible to visualize a completely virtual model of the ecoflow on a tablet: a model that is embedded in the physical space and freely scalable. This method of visualization allows the unit to be demonstrated in its entirety, and malfunctions in the operational sequence can be simulated for training purposes. It is the optimal way to make sure that technical personnel are prepared for commissioning.

We have added two more models to the app: the NIKKISO Non-Seal canned motor pump and the Lewa triplex, which features a visible crank drive in a mono-block design as well as a homogenization valve. Their functional principles can be visualized digitally.

REMOTE TROUBLESHOOTING

To extend the application of augmented reality to service and maintenance, Lewa took measures to launch an additional device: smart glasses. Thanks to the bi-directional smart glasses a service technician can simply connect through shared vision to see the plant through the eyes of the on-site technician when a malfunction occurs. As a result, malfunctions can often be remedied right away. The service technician gives verbal directions or uses the glasses to show the on-site technician instructions for action, documents, and drawings.

The service technician no longer needs to travel to site for minor problems and the unit’s downtime is significantly reduced. The smart glasses Lewa uses have been specially designed for industrial use. They are certified for ATEX zones, can be operated by voice control (“hands free”) and do not get in the way of the wearer’s full view of his or her environment.

FOR MORE INFORMATION

Lewa GmbH was founded as a family company by Herbert Ott and Rudolf Schestag in 1952. Today, it is the world’s leading manufacturer of metering pumps and process diaphragm pumps as well as complete metering packages for process engineering. The Leonberg, Germany-based company developed into an international Group within a few decades and saw further improvement in its position on the world market as part of integration into Japanese Nikkiso Co. Ltd. in 2009. As a research and production-oriented company, Lewa develops technologies and provides solutions for the vast array of applications among its customers. Its products are used mainly in the oil and gas industry, in gas odorization, in refineries and petrochemicals, as well as in the production of plastics, detergents, and cleaners. Additional application areas include the chemical industry, cosmetics industry, pharmaceuticals, and biotechnology, food and beverage industry, and energy utilities. For more information, visit www.lewa.com.

MODERN PUMPING TODAY, April 2020

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!