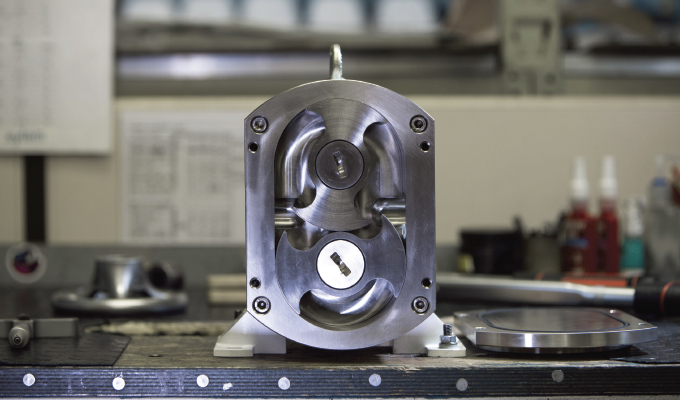

Xylem’s Jabsco brand has launched an update to its iconic Hy-line series of hygienic rotary lobe pumps, an enhanced redesign based on eleven years of research and development. The newly improved Hy-Iine Plus pump is the first update to the series since 2007 and features enhanced stability when in operation, a tri-lobe rotor design, ideal for high viscosity liquids, or Jabsco’s renowned single scimitar design, as well as the brand’s much-loved front-loaded mechanical seal system. Jabsco boasts a forty-year legacy in developing rotary lobe pumps, widely used by world-leading producers and brands in the food and beverage, dairy, personal care, and health care industries.

CHOCOLATE MEANS SWEET BUSINESS

The global confectionery market is one of the strongest performing sectors globally, expected to reach $232 billion by 2022, according to Allied Market Research. In Europe, chocolate confectionery specifically, showed the highest growth rate in recent years, accounting for more than one-third of the market.

When one of Europe’s leading chocolate confectionery companies needed to find an innovative and hygienic solution for a challenging glucose pumping application, the company turned to Xylem. Pumping delicate, viscous fluids can be a daily challenge for confectionery producers if an ill-performing pump is used, the effects on productivity and product quality can be costly.

THE PROJECT

Many confectionery manufacturers use high quantities of glucose, transporting it from tankers to internal canisters for use in the production processes. The company in question had been using a legacy gear pumping system for this purpose which they wanted to upgrade to a more reliable, efficient, and hygienic solution.

External gear pumps are widely used in hydraulic fluid power applications as well as in chemical installations to pump high viscosity fluids. These pumps use two meshing and contacting gears to pump fluid by displacement—one gear in the pump head turns the other gear. Despite their popularity, gear pumps can have a downside: the potential wear of gear material into pumped media.

THE SOLUTION

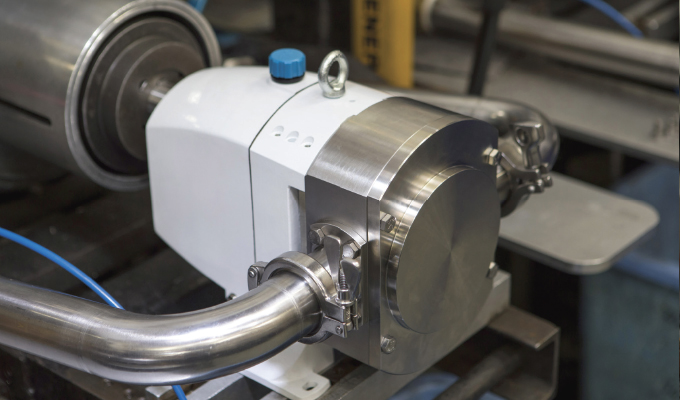

The new solution features two Xylem Jabsco Hy-Line+ hygienic rotary lobe pumps, specifically designed for the food industry and ideal for tank filling and emptying. Unlike external gear pumps, the lobes do not make contact and their gentle pumping action preserves the quality of ingredients, while the AISI 316 stainless steel construction makes them durable and food grade compliant.

Unlike most rotary lobe pumps on the market, Jabsco Hy-Line pumps including the new Hy-Line Plus, boast a front-loaded mechanical seal system. This delivers significant time and cost savings if maintenance on the pump is required; changing a seal on a front-loaded pump can be completed within fifteen minutes, compared to three to four hours on a non-front-loaded seal pump.

MEETING CUSTOMER NEEDS

Jabsco hygienic rotary lobe pumps are used by leading global manufacturers for ingredient unloading and transfer, tank filling and emptying, recirculation and mixing, portion and container filling, and sampling and filtration. Jabsco Hy-Line pumps are used in one of the world’s largest corn flake manufacturing plants as well as a leading international wafer and snack producer. World-leading brewers and dairy and confectionary producers rely on Jabsco rotary lobe pumps for efficient and reliable food production.

Xylem’s Jabsco brand is committed to swift order fulfilment with lobe pump orders completed and shipped to customers within five days. Xylem met the customer’s expectations by providing the perfect, cost-effective solution for the application, all within a short timeframe.

The customer is now also considering using Xylem technology for its chocolate processing applications, using the packed gland version of the Jabsco Hy-Line+ lobe series. The packed gland is a popular, convenient, and cost-effective sealing used in chocolate manufacturing. It is ideal for processing chocolate in its thick liquid form, and transferring it throughout the whole production process—from chocolate liquor to the conching process, down to the molding of chocolate bars.

While there’s no one-size-fits-all pumping solution in the food industry, the packed gland version of Jabsco Hy~Line+ lobe series is extremely flexible and makes it easy for Xylem to adapt it to the varying needs of customers, and to the different production processes and phases.

ENHANCEMENTS FOR NOW AND THE FUTURE

The new Jabsco Hy-line Plus is based on years of considered R&D investment, enhancing one of the most popular and successful rotary lobe pumps on the market. It’s not easy to better an icon but we’ve done it! The Hy-line Plus features a more stable operating design as well as a tri-lobe rotor option. This tri-lobe design improves inlet suction making it an ideal choice for pumping high viscosity materials such as chocolate and syrup.

FOR MORE INFORMATION

Peter Wright is director of engineering and product management at Xylem Specialty Flow Control Founded in Burbank, California, by Jack Streeter and Art Briggs in 1938, Xylem’s Jabsco brand boasts a rich heritage. From the outset, the brand was focused on solving customer challenges; the first Jabsco pump, featuring the world’s first flexible impeller, was designed in response to a customer requirement for condensate removal from air conditioning systems. For more information, visit www.xylem.com.

MODERN PUMPING TODAY, May 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!