MEGALERT: MotorGuard

MegAlert manufactures the MotorGuard patented testing and protection systems designed to detect insulation breakdown in critical motors. The system senses when the pump motor is offline and then performs a continuous dielectric test on the winding insulation until the equipment is started again. When an abnormal condition is detected the equipment can be locked out and a warning signal sent, indicating that the pump motor needs maintenance.

Reduce risk to save lives! The testing is done with a current limited non-destructive DC voltage from 500 to 5,000 VDC, which is safe for both personnel and the equipment. By automatically testing offline equipment customers can now predict and prevent impending failures, reduce unscheduled downtime repairs, and increase plant safety by not exposing maintenance personnel to dangerous Arc Flash conditions experienced when performing manual testing.

MotorGuard applies a current limited, fixed DC voltage to the motor windings during idle periods. A solid-state comparator circuit monitors measured leakage current to the ground. Two adjustable set points, factory preset to customer specifications, can be programmed to signal a pre-alarm, alarm, and lockout the equipment from operating if the low set point is exceeded. The manual reset feature enables a return to operational status only after the alarm condition has been corrected. MotorGuard will not impair normal operation of the equipment being monitored.

For over three decades, MegAlert has offered this patented, cost-effective, and proven technology with almost unlimited applications to multiple industries in both the private and government sectors.

For more information, visit www.megalert.com.

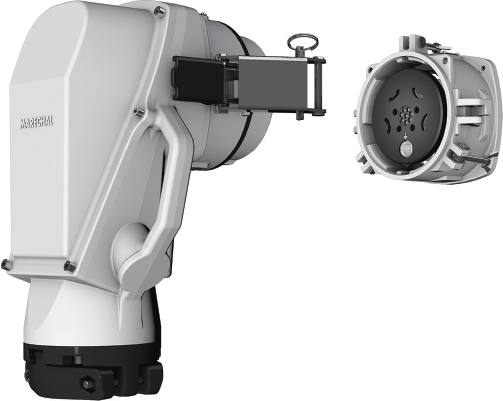

MELTRIC: P66 High-amp Industrial Plug and Receptacle

This year, Meltric, America’s leading manufacturer of switch-rated and standard-duty plugs and receptacles, launched the P66—a safe, high-powered, and highly durable electrical connection engineered for mobile electrification in harsh and demanding industrial environments.

Rated to deliver up to 660 amps at 1,100 volts alternating current and 1,500 volts direct current, P66 features IP66/IP67 ingress protection, IK10 impact resistance, and multiple built-in safety and control options, along with flexible installation configurations, making it one of the most rugged and versatile electrical connection solutions in the MELTRIC product portfolio.

For more information, visit www.meltric.com.

VAUGHAN COMPANY: Rotamix

Hydraulic mixing is a dirty job that requires a durable pump to keep things flowing smoothly. The Vaughan Rotamix® system is the world’s most cost-effective and durable means of mechanical hydraulic mixing for sludge tanks, digesters and other high-volume applications. By combining exceptional technology with a history of unmatched pump reliability and customer support, the Vaughan Rotamix® is engineered to handle whatever your job requires. Cutting-edge and American-made, the Vaughan Rotamix® pairs the original Vaughan Chopper Pump with a custom engineered layout of high-velocity nozzles to mix the tank, handling any tough solids.

For more information, call 360.249.4042, email info@chopperpumps.com, or visit www.chopperpumps.com.

PFANNENBERG: BABAA Thermal Management Products

Pfannenberg’s BABAA-approved portfolio includes a comprehensive range of thermal management solutions focusing on their DTS 3000 cooling units, available exclusively in 316 stainless steel configurations. These cooling units are engineered for durability, performance, and longevity in demanding environments, providing unparalleled protection and operational efficiency for sensitive electronics housed within electrical enclosures.

With this strategic expansion of its product lineup, Pfannenberg continues to lead the industry by aligning technological innovation with stringent compliance standards. By choosing Pfannenberg’s BABAA-approved products, customers can confidently participate in critical infrastructure developments, ensuring reliability, regulatory compliance, and supporting American industry.

For more information, visit www.pfannenbergusa.com/thermal-management/babaa-build-america-buy-america.

GRUNDFOS: DDA SMART Digital Dosing Pump

The new DDA brings next level safety and ease of use while keeping the accuracy for which it is renowned. The DDA is designed to help industries, building owners and utilities create a more sustainable future, providing steady, consistent chemical dosing for even the toughest applications. Grundfos-patented Digital Dosing continues to lead the way with many innovative technologies. This has resulted in the new DDA SMART Digital, which ensures the highest performance and accuracy for complex and demanding dosing applications. With its powerful variable-speed stepper motor and a turn-down ratio of up to 1:3000, the DDA ensures precise, smooth and continuous dosing in chemical treatment application across the full range.

For more information, visit www.grundfos.us.